cnc machine installation and commissioning In this section, we will consolidate the key takeaways from the entire blog post and provide a comprehensive list of best practices for CNC machine installation and commissioning. These . The Federal Group USA is one of the leading precision machined parts contract manufacturers in the country. As a metal fabricator with more than four decades of experience, TFG USA offers expertise and reliable solutions for simple or complex machined parts.

0 · W12 Hydraulic CNC Rolling Machine Installation Tutorial

1 · Unlocking Success: A Comprehensive Guide to CNC Machine

2 · Installation, commissioning and acceptance of CNC machine to

3 · Installation and Commissioning New CNC Machines

4 · Installation and Commissioning New CNC Machines

5 · How to Set Up a CNC Milling Machine: A Step

6 · How to Set Up CNC Machine for Beginners?

7 · CNC Commissioning: NC, PLC, Drive

8 · CNC Commissioning Guide

9 · A Step

Turn any grill into an outdoor smoker with our extra-large smoker box. Sized to fit inside a grill, the large, lidded box houses a solid tray for aromatic wood chips or fragrant herbs, with a perforated tray stacked on top to circulate heat and smoke.

By following this step-by-step guide, you can ensure a smooth and successful CNC machine installation and commissioning process. Remember that proper installation and regular maintenance are key to maximizing the performance and longevity of your CNC machine.

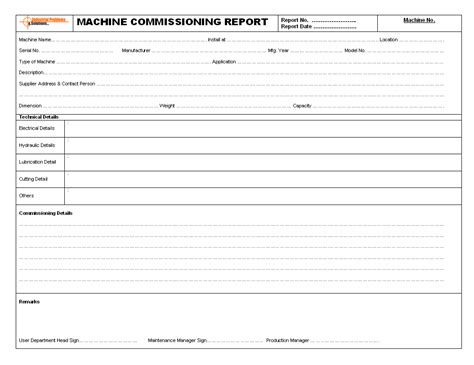

The CNC Commissioning Guide is the Step between having your machine built and having it running its first job. It is important to read carefully through this guide to avoid machine inaccuracy, poor performance, damaged .

W12 Hydraulic CNC Rolling Machine Installation Tutorial

Unlocking Success: A Comprehensive Guide to CNC Machine

For newcomers to CNC machinery, installation and commissioning are critical stages that lay the foundation for efficient operation. This process encompasses workshop preparation, professional machine installation, .In this section, we will consolidate the key takeaways from the entire blog post and provide a comprehensive list of best practices for CNC machine installation and commissioning. These . By the end, you’ll have the confidence to install your W12 hydraulic CNC rolling machine correctly, setting the stage for successful operations. Installing and commissioning a .Before the arrival of the CNC machine tool, the user should prepare for installation according to the machine tool foundation drawing provided by the machine tool manufacturer, and make .

Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems. The permissibleBy following this step-by-step guide, you can ensure a smooth and successful CNC machine installation and commissioning process. Remember that proper installation and regular maintenance are key to maximizing the performance and longevity of your CNC machine. The CNC Commissioning Guide is the Step between having your machine built and having it running its first job. It is important to read carefully through this guide to avoid machine inaccuracy, poor performance, damaged parts and the most important, your time trying to troubleshoot all possible issues just mentioned. For newcomers to CNC machinery, installation and commissioning are critical stages that lay the foundation for efficient operation. This process encompasses workshop preparation, professional machine installation, calibration, testing, and operator training.

In this section, we will consolidate the key takeaways from the entire blog post and provide a comprehensive list of best practices for CNC machine installation and commissioning. These guidelines will serve as a valuable reference for both beginners and experienced operators. By the end, you’ll have the confidence to install your W12 hydraulic CNC rolling machine correctly, setting the stage for successful operations. Installing and commissioning a four-roll plate bending machine requires careful planning, attention to detail, and adherence to safety protocols.Before the arrival of the CNC machine tool, the user should prepare for installation according to the machine tool foundation drawing provided by the machine tool manufacturer, and make reserved holes at the location where the anchor bolts are installed.

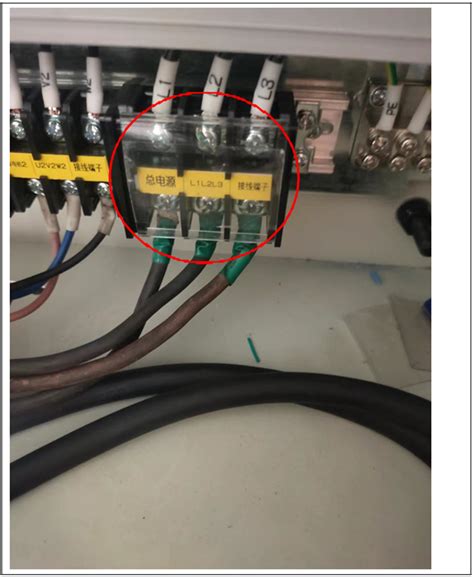

Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems. The permissibleProper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems. The permissible ambient The following is the correct steps for installing CNC machine. 1. Appearance Inspection Before Power On. (1) Machine tool electrical inspection: Open the machine tool electric control box, check whether the relay, contactor, fuse, servo motor speed, control unit socket, spindle motor speed control unit socket are loose.

Here I’ll share a handy checklist you can use whenever you’re bringing a new Okuma CNC machine into your shop. Check Electrical Requirements: Find out how much current your new CNC machine will draw so you can prepare your electrical for it.By following this step-by-step guide, you can ensure a smooth and successful CNC machine installation and commissioning process. Remember that proper installation and regular maintenance are key to maximizing the performance and longevity of your CNC machine. The CNC Commissioning Guide is the Step between having your machine built and having it running its first job. It is important to read carefully through this guide to avoid machine inaccuracy, poor performance, damaged parts and the most important, your time trying to troubleshoot all possible issues just mentioned. For newcomers to CNC machinery, installation and commissioning are critical stages that lay the foundation for efficient operation. This process encompasses workshop preparation, professional machine installation, calibration, testing, and operator training.

Installation, commissioning and acceptance of CNC machine to

In this section, we will consolidate the key takeaways from the entire blog post and provide a comprehensive list of best practices for CNC machine installation and commissioning. These guidelines will serve as a valuable reference for both beginners and experienced operators. By the end, you’ll have the confidence to install your W12 hydraulic CNC rolling machine correctly, setting the stage for successful operations. Installing and commissioning a four-roll plate bending machine requires careful planning, attention to detail, and adherence to safety protocols.Before the arrival of the CNC machine tool, the user should prepare for installation according to the machine tool foundation drawing provided by the machine tool manufacturer, and make reserved holes at the location where the anchor bolts are installed.Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems. The permissible

Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems. The permissible ambient The following is the correct steps for installing CNC machine. 1. Appearance Inspection Before Power On. (1) Machine tool electrical inspection: Open the machine tool electric control box, check whether the relay, contactor, fuse, servo motor speed, control unit socket, spindle motor speed control unit socket are loose.

Installation and Commissioning New CNC Machines

Installation and Commissioning New CNC Machines

How to Set Up a CNC Milling Machine: A Step

How to Set Up CNC Machine for Beginners?

{Universal Compatibility} This junction box round fits most surveillance cameras, including bullet cameras and solar panel types. Also compatible with REOLINK, HEIMVISION, ZOSI, HISEEU, ring,wyze cameras. {IP66 Waterproof} Made of aluminum with IP66 waterproof rating, this junction box protecting security cameras and cables from harsh elements.

cnc machine installation and commissioning|Unlocking Success: A Comprehensive Guide to CNC Machine