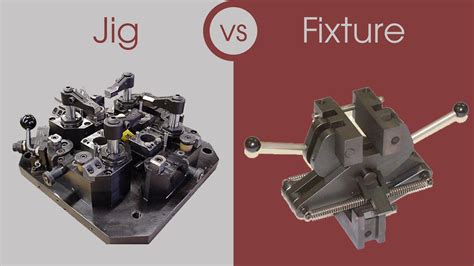

fixture and jig part cnc machining Jigs are mostly provided with extra parts to guide the cutting tools, but fixtures’ design aspects are broader to facilitate different workpiece shapes and sizes. . while fixtures are more universal and may be applied in several machining operations. Jigs and fixtures are two distinct and dissimilar types of manufacturing tools and . $298.43

0 · what is jig & fixture

1 · types of jigs and fixtures

2 · jigs and fixtures diagram

3 · jig and fixture examples

4 · jig and fixture difference

5 · functions of jigs and fixtures

6 · differentiate between jigs and fixture

7 · differences between jigs and fixtures

Accu-Router, Inc. has a mission to provide high-performance, CNC routers designed to significantly reduce user processing costs to manufacture and assemble non-metallic materials.

what is jig & fixture

Discover CNC jigs, fixtures and workholding solutions for milling machines. Get tips and ideas to optimize your machining process at CNCCookbook.

types of jigs and fixtures

Jigs and fixtures facilitate the machining of parts with complex shapes and geometries, as tools and workpieces can be manipulated accurately across different angles and directions. With jigs and fixtures, one or more tool . In CNC machining, jigs are readily accessible tools, manifesting in a variety of types. Below are some common types of jigs employed in machining processes: . Machinists can effortlessly manufacture heavy and intricately .

Jigs are mostly provided with extra parts to guide the cutting tools, but fixtures’ design aspects are broader to facilitate different workpiece shapes and sizes. . while fixtures are more universal and may be applied in several machining operations. Jigs and fixtures are two distinct and dissimilar types of manufacturing tools and . Without a milling fixture, it would be difficult to produce accurate and repeatable parts with a CNC mill. Milling fixtures are typically made from hardened steel or aluminum and can be custom-designed to fit the specific . A third jig chuck grasps the workpiece for rotation. 3-jaw jig chucks are versatile but lack accuracy. 4-jaw jig chucks provide precise clamping but setup takes longer. . When you install a fixture on the CNC machine, you have to measure its exact position and enter those measurements into the CNC control. . This allows the CNC machine to .

Be sure to check out the brand new series on our FREE CNC Academy here: https://academy.titansofcnc.com/category/the-art-of-fixturingCNC Machining is what we.

Highturn is a full service manufacturer offering value added services, such as machining parts and jig & fixtures operations. Our tool room is equipped with CNC machining facilities which are supported by skilled toolmakers and CAD/CAM software.What started as a CNC machine shop in tamilnadu focused on making the most difficult parts in aerospace, has transitioned into a massive reality TV series and a tamilnadu -first CNC educational platform recognized and utilized by a global network of engineers, machinists, hobbyists, students, and educators.

jigs and fixtures diagram

jig and fixture examples

cnc deep hole drilling machine

They are used for machining parts that require low clamping force and speed. • Magnetic fixtures. These are fixtures that use magnetic force to clamp the workpiece. They are used for machining parts that are made of ferromagnetic materials. Advantages of Jigs and Fixtures • Increased precision: Both jigs and fixtures improve overall precision.

C&C Tool & Machine. Specializing in Design and Manufacturing of Fixtures, Gages, Jigs, Dies, CNC 3 and 4 Axis Milling and CNC Turning, and Machine Parts. We are also very proud to introduce our new equipment our WaterJet Machining Center. Please view the OMAX WaterJet page to see our equipment and find out more about the performance. Combining .

Purchase Jig and fixture components online from stock. Visit WDS Components for Jig and Fixture Components at great prices from a UK supplier. . CNC Fixtures. Mitee-Bite. Shaft Collars. Location Pins. Clamps. Magnets. MicroLoc. Profiles. Toggle Clamps. . Steel pin quarter turn clamp locks with Plastic wing nut rotary knob 2 parts in this . jigs and fixtures are the devices that help increase the rate of identical parts and reduce the human efforts required for producing these parts.. It has already been emphasized earlier that a center lathe is a suitable machine tool for producing individual parts of different shapes and sizes, but for producing similar articles in great numbers its use will not be .

CNC Milling. 3-axis , 4- axis and 5-axis milling; Complex contours and pocketing; High-speed machining; CNC Turning. Precision turning for cylindrical parts; Threading, grooving, and facing; Multi-axis live tooling; Press Components. Jigs and Fixtures. Moulds and Dies. Press Tools. Product PrototypesHow to Manufacture Jigs and Fixtures. CNC machining is the most common manufacturing process for creating jigs and fixtures since volumes are typically low. In some cases, 3D printing is the most logical process when the geometry is too difficult or costly to machine. . For a handful of parts, we recommend our CNC machining capabilities for .

Our tooling, jig and fixture CNC machining services _____ Penta has many years of experience manufacturing precision tooling, jigs and fixtures and prototype development. This means we can offer a comprehensive service offering a range of secondary processes including plating, specialist coatings and wire inserts.Services Jig & Fixture Jigs & Fixtures Ensuring Precision and Efficiency in Your Manufacturing Process Precision Engineering Malaysia | 5-Axis CNC Machining Boost your manufacturing efficiency and accuracy with LBC Engineering’s . 1. Milling Fixtures. The plain milling fixture is a versatile tool that offers flexibility and precision. It securely holds the workpiece, offering three degrees of freedom, ensuring that it is milled accurately regardless of its .

If you were faced with a simple bolt pattern with +/-.005 tolerances on a large, awkward or hard to fixture part, would you use a drill jig to put those holes in? Example, 4x 1/4-20 threaded holes on a large 2" thick steel plate cut in a funny . Fixtures that reduce setup time include SMED (single-minute exchange of die), Milling Fixtures, soft jaws, hex milling fixtures, and many others. Parts Protection. Jigs and fixtures play a crucial role in safeguarding workpieces during machining, aiding in the maintenance of desired surface finishes and proper runout. How to Make Jigs and Fixtures. CNC machining and 3D printing are the two major ways of making a jig and fixture. However, both processes depend heavily on complexity, volume to be produced, and difficulty making them. . Their major difference is in their main functions. A jig works by guiding the machine part, e.g., a cutter while doing its .

For the most part, yes. You could always bolt on sections of hardened material in critical areas like locating surfaces. The main argument for using aluminum is weight. If you're loading/unloading parts on the fixture plates outside of the machine, the 2/3 weight savings can make a huge difference if you don't have a crane.The company has more than 50 high-precision CNC machine tools for machining parts. This includes Brother CNC machine tools imported from Japan, Mazak brand five-axis VARIAXIS i-700 machine tools, Mazak brand QTE-200L CNC lathes, Taikan brand T-500B machine tools and other precision machining equipment from China.In CNC manufacturing, precision and efficiency are paramount. Whether you’re producing complex aerospace components or assembling consumer electronics, the role of jigs and fixtures cannot be overstated. These unassuming tools serve as the backbone of modern production, streamlining processes, enhancing quality, and ultimately contributing to the bottom line. .

Offers higher durability and strength, especially in heavy-duty applications; CNC machining produces robust jigs and fixtures for high-load environments. Surface Finish and Size Constraints: Good for smaller, intricate fixtures; post-processing may be needed for smoother finishes; larger parts may suffer from warping

CNC milling fixtures are devices used in CNC (Computer Numerical Control) milling machines to hold, support, and position a workpiece securely during the machining process. In this manufacturing process, rotary table fixtures, vise fixtures, fixture plates, T-slot, and indexing fixtures are common types of CNC milling fixtures.These fixtures ensure precision, .

OEM CNC Machining Aluminum Parts for Robot Spare Parts US CNC fixture, also called jig, is a kind of device used to clamp workpiece and guide cutting tool on CNC machine tool. CNC fixture can adapt to the high precision, high efficiency, multi-directional processing simultaneously, digital program control and single piece small batch production of computer numerical control machine tools..50-35.00 / Piece OEM Custom High Precison Mould Parts Core Insert ProcessingFixturing is an art. In many cases, it's the most important aspect of making a part or making money on your parts and not everyone can do it. Experience is.

jig and fixture difference

functions of jigs and fixtures

CNC-Shopping offers spare parts and CNC machine tools for assembly lines, robotics and controllers. We specialize in reconditioned CNC parts that are hard to find or obsolete. Find name brands like Fanuc, Mitsubishi, Mazak, Siemens, .

fixture and jig part cnc machining|functions of jigs and fixtures