cnc lathe machine standard operating procedure During operation, keep hands a safe distance away and only use adjustment tools on lathe to maneuver work piece. Know the location of start and stop switches or buttons and keep the . well in that case then I think I would go with an 18 gauge sheet metal and make some stiffeners by bending strips into angles to be tacked to the underside of the floor..be sure and put some reinforcing in way of the seat belt attachments and at the points where the cab bolts down..if you can maintain the rockers on the cabs as they provide good strength to the cab .

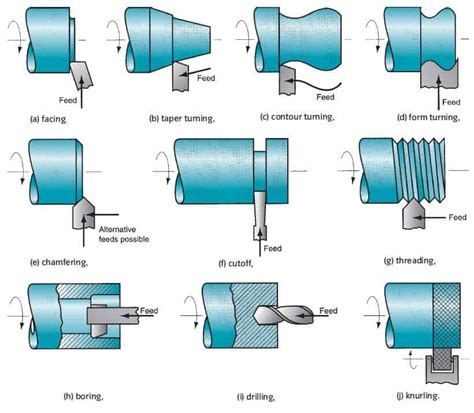

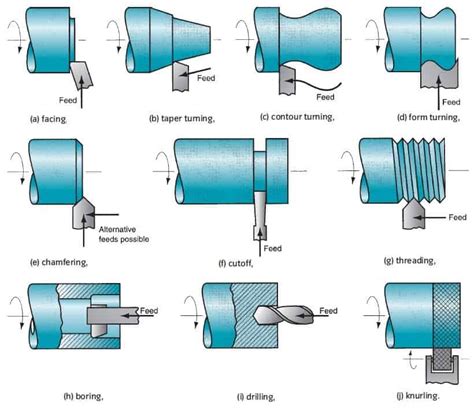

0 · turning operations on lathe machine

1 · turning operation lathe

2 · turning lathe diagram

3 · cnc turning lathe machine

4 · cnc lathe setup

5 · cnc lathe machine operations

6 · basic turning operations

7 · application of cnc lathe machine

$34.95

Operating a CNC lathe machine requires precision, expertise, and adherence to standard operating procedures (SOPs). To ensure your team operates the machine safely and .All stock must be properly secured in the lathe chuck or mounted prior to the machining process taking place. Use the correct sized clamp or vise for the stock being machined. Turn the chuck .

Locate and ensure you are familiar with the operation of the ON/OFF start and E-Stop. Ensure all guards are in place. Check that the job is clamped tight in the chuck. Remove all tools from the .

This standard operating procedure (SOP) provides comprehensive guidelines for operating a CNC machine and outlines the key steps to be followed during machine setup, programming, and .During operation, keep hands a safe distance away and only use adjustment tools on lathe to maneuver work piece. Know the location of start and stop switches or buttons and keep the .

Though the CNC lathe machine’s operations are mechanical, it’s designed for automated precision machining. The primary CNC lathe machine operations are: Cutting involves separating large amounts of material from a .tools or pieces of equipment: Mill, Lathe, Planer, Drill Press, Pedestal Grinder, & Band Saw. GENERAL SAFETY TIPS • Safety glasses with side shields must be worn at all times.

turning operations on lathe machine

Ever wondered how to safely and efficiently operate a lathe? This article breaks down the essential procedures and precautions every operator must follow. From pre-operation inspections to precise shutdown protocols, it covers all .

Operating a CNC lathe machine requires precision, expertise, and adherence to standard operating procedures (SOPs). To ensure your team operates the machine safely and efficiently, ClickUp's CNC Lathe Machine SOP Template is here to help!All stock must be properly secured in the lathe chuck or mounted prior to the machining process taking place. Use the correct sized clamp or vise for the stock being machined. Turn the chuck or faceplate by hand to ensure there is no binding or danger of the work striking any part of the lathe.

Locate and ensure you are familiar with the operation of the ON/OFF start and E-Stop. Ensure all guards are in place. Check that the job is clamped tight in the chuck. Remove all tools from the bed slides of the machine. Ensure correct speed machining process is selected. Remove the chuck key before starting the lathe.

This standard operating procedure (SOP) provides comprehensive guidelines for operating a CNC machine and outlines the key steps to be followed during machine setup, programming, and maintenance. Step 1: Machine Setup. 1. Ensure a clean .

turning operation lathe

During operation, keep hands a safe distance away and only use adjustment tools on lathe to maneuver work piece. Know the location of start and stop switches or buttons and keep the drill and other materials. Use only properly sharpened drill bits, sockets and chucks in good condition.

Though the CNC lathe machine’s operations are mechanical, it’s designed for automated precision machining. The primary CNC lathe machine operations are: Cutting involves separating large amounts of material from a workpiece with a sharp-edged cutting tool.The document provides standard operating procedures for using a lathe. It outlines several safety steps: [1] securely clamp stock before machining, [2] check for binding or risk of contact, [3] ensure the tool will not hit the chuck, [4] check clearances before starting.

With a CNC lathe, the tooling operates according to a program written and uploaded to the machine, allowing for highly precise and repeatable production. How does a CNC lathe work? Read on to learn the answer — as well as some tips for operation in the process.tools or pieces of equipment: Mill, Lathe, Planer, Drill Press, Pedestal Grinder, & Band Saw. GENERAL SAFETY TIPS • Safety glasses with side shields must be worn at all times.

Ever wondered how to safely and efficiently operate a lathe? This article breaks down the essential procedures and precautions every operator must follow. From pre-operation inspections to precise shutdown protocols, it covers all .Operating a CNC lathe machine requires precision, expertise, and adherence to standard operating procedures (SOPs). To ensure your team operates the machine safely and efficiently, ClickUp's CNC Lathe Machine SOP Template is here to help!

All stock must be properly secured in the lathe chuck or mounted prior to the machining process taking place. Use the correct sized clamp or vise for the stock being machined. Turn the chuck or faceplate by hand to ensure there is no binding or danger of the work striking any part of the lathe.Locate and ensure you are familiar with the operation of the ON/OFF start and E-Stop. Ensure all guards are in place. Check that the job is clamped tight in the chuck. Remove all tools from the bed slides of the machine. Ensure correct speed machining process is selected. Remove the chuck key before starting the lathe.This standard operating procedure (SOP) provides comprehensive guidelines for operating a CNC machine and outlines the key steps to be followed during machine setup, programming, and maintenance. Step 1: Machine Setup. 1. Ensure a clean .During operation, keep hands a safe distance away and only use adjustment tools on lathe to maneuver work piece. Know the location of start and stop switches or buttons and keep the drill and other materials. Use only properly sharpened drill bits, sockets and chucks in good condition.

turning lathe diagram

Though the CNC lathe machine’s operations are mechanical, it’s designed for automated precision machining. The primary CNC lathe machine operations are: Cutting involves separating large amounts of material from a workpiece with a sharp-edged cutting tool.The document provides standard operating procedures for using a lathe. It outlines several safety steps: [1] securely clamp stock before machining, [2] check for binding or risk of contact, [3] ensure the tool will not hit the chuck, [4] check clearances before starting.

electrical no junction boxes

electrical outlet box extensions at lowes

Your best course of action may be to excavate until you find the conduit from each light niche, cut it, thread it, and run more brass conduit to a location where you can stub up for a code compliant box.

cnc lathe machine standard operating procedure|cnc lathe setup