about cnc machines in pdf The multi-axis CNC machining family includes three processes: Indexed 5-axis CNC milling: During indexed 5-axis milling operations, not only can the cutting tools move along the three . $329.99

0 · types of cnc machines PDF

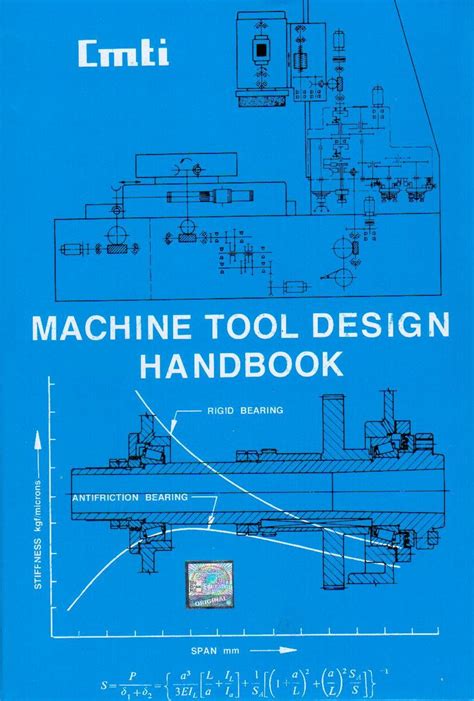

1 · cnc machine tool design PDF

2 · cnc machine manual PDF

3 · cnc machine drawing PDF

4 · cnc machine codes list PDF

5 · cnc machine books free download PDF

6 · cnc machine basic knowledge PDF

7 · cnc machine PDF download

Learn why MIG, pulsed MIG, TIG and pulsed TIG are the ideal choices when welding sheet metal. When welding thin metal, the main objective is to avoid warping, burn-through and excessive heat-affected zones while still ensuring the weld has enough mechanical strength for the application.

The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC electrical discharge machining .Explain what computer numerical control (CNC) is and what basic components comprise CNC systems. State the objectives, advantages, and special requirements concerning CNC use. .What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the .

The multi-axis CNC machining family includes three processes: Indexed 5-axis CNC milling: During indexed 5-axis milling operations, not only can the cutting tools move along the three .CNC Motion Control • Machine locates axes from programmed commands • Components: drive screws, CNC guideways, servo motorsCNC Machining . Intro to CNC Machining • CNC stands for computer numeric controlled. It refers to any machine tool (i.e. mill, lathe, drill press, etc.) which uses a computer to electronically .

Featuring hundreds of color images and schematic diagrams, CNC Handbook explains machining fundamentals and shows you how to build and safely operate fully automated, technically sophisticated mechatronic equipment.CNC is an acronym for Computer Numerical Control, where a computer is connected to the mill, along with electrical drives and sensors for a complete system. This computer controls the .

Computer Numerical Control (CNC) machines have become a major part in almost all types of manufacturing processes and is used in a wide range of applications. From aerospace applications to the manufacturing of energy .This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional prototypes are made from materials like aluminum, steel and polycarbonate that cannot be produced with widely available additive RapidThe machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC electrical discharge machining (EDM) CNC grinding machines CNC cutting machines (laser, plasma, electron, or flame) CNC fabrication machines (sheet metal punch press,

types of cnc machines PDF

Explain what computer numerical control (CNC) is and what basic components comprise CNC systems. State the objectives, advantages, and special requirements concerning CNC use. Identify the different media used to input and store CNC programs. Describe the two different punched-tape formats used with CNC machines.What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.The multi-axis CNC machining family includes three processes: Indexed 5-axis CNC milling: During indexed 5-axis milling operations, not only can the cutting tools move along the three linear axes, but between operations, the machining table and tool head can swivel in two directions.CNC Motion Control • Machine locates axes from programmed commands • Components: drive screws, CNC guideways, servo motors

CNC Machining . Intro to CNC Machining • CNC stands for computer numeric controlled. It refers to any machine tool (i.e. mill, lathe, drill press, etc.) which uses a computer to electronically control the motion of one or more axes on the machine. • The development of NC machine tools started from a task supported Featuring hundreds of color images and schematic diagrams, CNC Handbook explains machining fundamentals and shows you how to build and safely operate fully automated, technically sophisticated mechatronic equipment.

CNC is an acronym for Computer Numerical Control, where a computer is connected to the mill, along with electrical drives and sensors for a complete system. This computer controls the movement of the machine axis. CNC machines are very precise, with precision and repeatability that can exceed what is possible through manual movements.

Computer Numerical Control (CNC) machines have become a major part in almost all types of manufacturing processes and is used in a wide range of applications. From aerospace applications to the manufacturing of energy systems and medical robots, we see a major reliance on CNC machines.This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional prototypes are made from materials like aluminum, steel and polycarbonate that cannot be produced with widely available additive RapidThe machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC electrical discharge machining (EDM) CNC grinding machines CNC cutting machines (laser, plasma, electron, or flame) CNC fabrication machines (sheet metal punch press,

Explain what computer numerical control (CNC) is and what basic components comprise CNC systems. State the objectives, advantages, and special requirements concerning CNC use. Identify the different media used to input and store CNC programs. Describe the two different punched-tape formats used with CNC machines.What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.

The multi-axis CNC machining family includes three processes: Indexed 5-axis CNC milling: During indexed 5-axis milling operations, not only can the cutting tools move along the three linear axes, but between operations, the machining table and tool head can swivel in two directions.CNC Motion Control • Machine locates axes from programmed commands • Components: drive screws, CNC guideways, servo motors

cnc machine tool design PDF

CNC Machining . Intro to CNC Machining • CNC stands for computer numeric controlled. It refers to any machine tool (i.e. mill, lathe, drill press, etc.) which uses a computer to electronically control the motion of one or more axes on the machine. • The development of NC machine tools started from a task supported Featuring hundreds of color images and schematic diagrams, CNC Handbook explains machining fundamentals and shows you how to build and safely operate fully automated, technically sophisticated mechatronic equipment.CNC is an acronym for Computer Numerical Control, where a computer is connected to the mill, along with electrical drives and sensors for a complete system. This computer controls the movement of the machine axis. CNC machines are very precise, with precision and repeatability that can exceed what is possible through manual movements.

electrical wiring metal boxes

electricity circuit box

In this comprehensive guide, we delve into the nuanced techniques and best practices that elevate your sheet metal welding projects to new heights. Whether you are tackling automotive repairs or creating custom metal fabrications, the finesse of stick welding can make all the difference in achieving durable and seamless results.

about cnc machines in pdf|cnc machine basic knowledge PDF