electric iron box circuit diagram as linear feedback When current passes through the coil or heating element of an electric iron. It starts getting hot. in this video , we are trying to explain the complete working of a electric iron . To weld thin metal, choose an appropriate process (TIG or MIG with low amperage), use a smaller diameter wire or filler rod, and adjust travel speed to prevent burn-through. Employ a pulsing technique, stitch welding, or .

0 · iron box wiring types

1 · iron box wiring diagram pdf

2 · iron box circuit diagram

3 · electric iron box wiring

4 · electric iron box diagram

There are several types of welding, including: autogenous, homogeneous, heterogeneous, brazing, soldering, gas and torch welding, and pressure or cold welding. Explore more about this area of knowledge by taking a look at our more than 20 books on welding in PDF format.

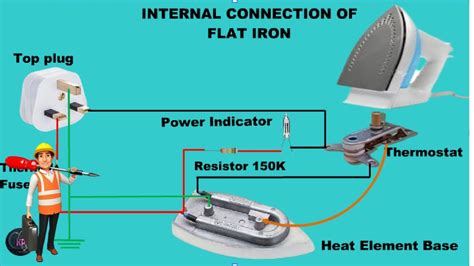

The circuit diagram of an electric iron box can be helpful when troubleshooting problems and diagnosing any potential issues with the appliance. It can also be useful for .A circuit diagram of an electric iron is a simplified representation of the .Working of Iron Box: A simple wiring diagram of electric iron has been given below. The single phase AC supply is connected to the heating element . A circuit diagram of an electric iron is a simplified representation of the components used to power and operate the device. It includes all the wiring, switches, and connectors that make up the power supply and circuitry, as well .

When current passes through the coil or heating element of an electric iron. It starts getting hot. in this video , we are trying to explain the complete working of a electric iron . Specific topics that will be covered include the working principles, types, parts and specifications of an electric iron. Diagrams and details are provided about the sole plate, pressure plate, heating element, thermostat and .Here we will discuss the detailed operation of an automatic electric iron and a temperature control system. 1. Automatic Electric Iron. Consider an example of automatic electric iron which acts as a closed-loop system. The figure below . The working of an electric iron is very simple – it draws electricity from the mains and heats a coil inside. This heat is then transferred to the bottom plate, which is pressed against the clothing to remove wrinkles.

Quick-access build box lets you draw basic circuit primitives quickly, while allowing access to a wide assortment of non-linear elements, feedback elements, digital / mixed-mode components, and custom drawing tools. Easy-wire mode .This paper presents how we can introduce a modification to the conventional electrical irons so that the handling of iron boxes becomes easier with minimum manual intervention. While . Reference:- - http://hyperphysics.phy-astr.gsu.edu/hbase/thermo/thexp.html- https://www.engineeringtoolbox.com/linear-expansion-coefficients . The circuit diagram of an electric iron box can be helpful when troubleshooting problems and diagnosing any potential issues with the appliance. It can also be useful for wiring new electric irons, as well as understanding the basics of how electricity works.

iron box wiring types

Working of Iron Box: A simple wiring diagram of electric iron has been given below. The single phase AC supply is connected to the heating element through thermostat. Working principle of the heating process in electric iron is briefed below. Fig. Wiring diagram of electric iron

A circuit diagram of an electric iron is a simplified representation of the components used to power and operate the device. It includes all the wiring, switches, and connectors that make up the power supply and circuitry, as well as the safety features.When current passes through the coil or heating element of an electric iron. It starts getting hot. in this video , we are trying to explain the complete working of a electric iron with the help.

Specific topics that will be covered include the working principles, types, parts and specifications of an electric iron. Diagrams and details are provided about the sole plate, pressure plate, heating element, thermostat and other parts of an electric iron.Here we will discuss the detailed operation of an automatic electric iron and a temperature control system. 1. Automatic Electric Iron. Consider an example of automatic electric iron which acts as a closed-loop system. The figure below represents the block diagram with major components: The working of an electric iron is very simple – it draws electricity from the mains and heats a coil inside. This heat is then transferred to the bottom plate, which is pressed against the clothing to remove wrinkles.Quick-access build box lets you draw basic circuit primitives quickly, while allowing access to a wide assortment of non-linear elements, feedback elements, digital / mixed-mode components, and custom drawing tools. Easy-wire mode lets you .

iron box wiring diagram pdf

This paper presents how we can introduce a modification to the conventional electrical irons so that the handling of iron boxes becomes easier with minimum manual intervention. While ironing clothes, the most important thing we focus on is not to .

Reference:- - http://hyperphysics.phy-astr.gsu.edu/hbase/thermo/thexp.html- https://www.engineeringtoolbox.com/linear-expansion-coefficients-d_95.html- https. The circuit diagram of an electric iron box can be helpful when troubleshooting problems and diagnosing any potential issues with the appliance. It can also be useful for wiring new electric irons, as well as understanding the basics of how electricity works.

explosion proof junction box with terminals

Working of Iron Box: A simple wiring diagram of electric iron has been given below. The single phase AC supply is connected to the heating element through thermostat. Working principle of the heating process in electric iron is briefed below. Fig. Wiring diagram of electric iron A circuit diagram of an electric iron is a simplified representation of the components used to power and operate the device. It includes all the wiring, switches, and connectors that make up the power supply and circuitry, as well as the safety features.

When current passes through the coil or heating element of an electric iron. It starts getting hot. in this video , we are trying to explain the complete working of a electric iron with the help. Specific topics that will be covered include the working principles, types, parts and specifications of an electric iron. Diagrams and details are provided about the sole plate, pressure plate, heating element, thermostat and other parts of an electric iron.Here we will discuss the detailed operation of an automatic electric iron and a temperature control system. 1. Automatic Electric Iron. Consider an example of automatic electric iron which acts as a closed-loop system. The figure below represents the block diagram with major components:

The working of an electric iron is very simple – it draws electricity from the mains and heats a coil inside. This heat is then transferred to the bottom plate, which is pressed against the clothing to remove wrinkles.Quick-access build box lets you draw basic circuit primitives quickly, while allowing access to a wide assortment of non-linear elements, feedback elements, digital / mixed-mode components, and custom drawing tools. Easy-wire mode lets you .This paper presents how we can introduce a modification to the conventional electrical irons so that the handling of iron boxes becomes easier with minimum manual intervention. While ironing clothes, the most important thing we focus on is not to .

iron box circuit diagram

electric iron box wiring

electric iron box diagram

How Do You Use a Stick Welder to Weld Thin Metal? The other name for the stick welding procedure is SMAW (Shielded Metal Arc Welding). This welding technique is older as compared to other types. However, it’s an easy procedure that guarantees you potent welds. Image Credit: vespaburoks, Pixabay

electric iron box circuit diagram as linear feedback|iron box wiring types