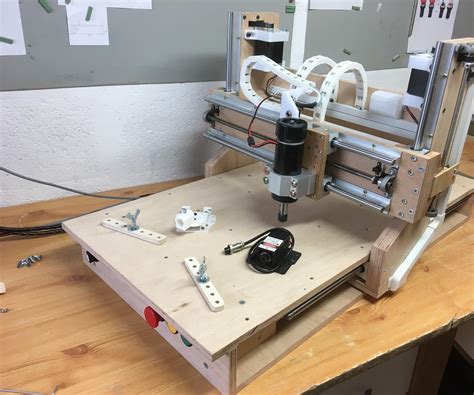

best cnc wood machines Whether you're creating intricate designs in wood, precise cuts in metal, or detailed engravings on glass and plastic, CNC routers offer unmatched versatility and accuracy. In the past, achieving such precision manually was . Search for used bunn, coffee makers. Find Bunn and Freightliner for sale on Machinio.

0 · hobby cnc machine for wood

1 · c&c machine for woodworking

2 · best woodworking cnc for hobbyists

3 · best rated cnc woodworking machines

4 · best hobby wood cnc machine

5 · best cnc woodworking machines

6 · affordable cnc machines for woodworking

7 · affordable cnc machine for wood

Our capabilities allows our fabrication shop to mill, weld, cut, assemble and kit metal components for globally recognized companies. 4020 Garner Road, Riverside, CA 92501 800-224-2611 AS9100 and ISO 9001 Certified

The Best CNC Routers for Woodworking. 1. Carbide 3D Shapeoko 4: Best Wood CNC Carving Machine for DIYers; 2. BobsCNC Evo 4: Best CNC Wood Router for the Money; 3. Axiom Iconic Series: User-Friendly Wood Carving Machine; 4. BobsCNC KL744: Best Large CNC Machine for Woodworking; 5. ZMorph . See more Best CNC Router Overall: MYSWEETY CNC Pro Engraver Machine Shop Now Runner Up: SainSmart Genmitsu CNC Router Machine Shop Now Honorable Mention: .

Whether you're creating intricate designs in wood, precise cuts in metal, or detailed engravings on glass and plastic, CNC routers offer unmatched versatility and accuracy. In the past, achieving such precision manually was . Here are the top wood CNC machines ideal for home projects: Genmitsu CNC 3018-PRO machine: The Genmitsu 3018-Pro machine is perfect for beginners, offering noiseless .0.00

9.009.999.99

9.999.00As professionals in the woodworking and metalworking industry, we understand the significance of precision and efficiency in CNC router machines. Take, for example, the Genmitsu CNC 3018-PRO Router Kit, which has garnered . We’re going to be taking a look at some of the best wood CNC machines out there. Using the right router, you can create anything with wood beautifully and accurately. But if you use a low-quality CNC router, you’re .

In this guide, we’ll reveal the very best 4×8 CNC routers available right now. We’ll start with the cheapest 4×8 CNC machine available right now and then work our way up to the best CNC machine for professional use, so that .

CNC technology revolutionizes the woodworking process by automating the cutting of various materials, notably wood, thus offering a streamlined and efficient approach. Looking for the right desktop CNC machine can be tricky. Here’s an overview of the best CNC routers big, small, multidimensional, and everything in between. Poplar is an OK wood - but on small and delicate - no. Maple - is a really dense and close grained wood and in my opinion is the best for small delicate stuff. I prefer Corian over wood for the stuff I am talking about. I don't really know what you are trying to do. Depending on the job - I will select different materials. Not always wood.

Re: New to CNC- Looking for best fonts and Bits Post by Adrian » Wed Feb 10, 2021 4:30 pm For very small letters like that you're nearly always going to be looking at the Single Line fonts (it's a choice in the Text Tool) and a profile toolpath set to be on the vector with a very fine tool like a 30 or 45 degree engraving bit.

That Amanda tool bit is mainly for surfacing, which I would only use very small amounts of DOC. Another factor is the type of wood you are carving/cutting. Softer wood like pine will easily create fuzzies and burrs. Again, you could try to reduce the pass depth, or run a finish carve over the last the carve.

scottp55 Vectric Wizard Posts: 4801 Joined: Thu May 09, 2013 11:30 am Model of CNC Machine: ShopbotDesktop 5.5"Z/spindle/VCP12.* Scott, I took all your suggestions and I'm amazed at the lettering detail I'm getting on bad wood, can't wait till I can get some maple to work with. I faced the wood on my CNC, marked location and orientation of the piece in the jig. I then took the piece off the CNC and sanded down the face to finished grade. For example I can clamp boards at 45 degrees inside my CNC frame and use a simple end mill to mill off the end at 45 degrees relative to the board. You could use the moulding toolpath, but must be prepared to let the ball nosed bit cut into the spoilboard a little.

What is really exciting is ripping the chuck right off the spindle, or the toolpost. Just so everyone knows, people get killed regularly by lathes. Usually it is the piece coming off and smashing them in the head. And no, a face shield does not protect anyone from a 50lb piece of wood going about 100MPH hitting a person in the face. I'm using V-Carve Dexktop 8.5 and a Shapeoko 3 XXL CNC with a 1/32nd ball nose mill. Even on large plaques certain letters do not carve well. It's very possible I'm trying to cut the letters too deep. I am currently using a 1/4" 60 degree V bit for inlays. I occasionally have tearout or chipping of the edges on my male parts. Often, these tearouts end up buried in the female part and cause no issues, but occasionally they do. Seems the harder the wood, the more prone it is to tear out. A recent piece of purpleheart was unusable due to the .

mtylerfl Vectric Archimage Posts: 5928 Joined: Thu Jan 29, 2009 3:54 am Model of CNC Machine:-CarveWright CNC -ShopBot Buddy PRSAlpha Poplar is an OK wood - but on small and delicate - no. Maple - is a really dense and close grained wood and in my opinion is the best for small delicate stuff. I prefer Corian over wood for the stuff I am talking about. I don't really know what you are trying to do. Depending on the job - I will select different materials. Not always wood. Re: New to CNC- Looking for best fonts and Bits Post by Adrian » Wed Feb 10, 2021 4:30 pm For very small letters like that you're nearly always going to be looking at the Single Line fonts (it's a choice in the Text Tool) and a profile toolpath set to be on the vector with a very fine tool like a 30 or 45 degree engraving bit.

hobby cnc machine for wood

That Amanda tool bit is mainly for surfacing, which I would only use very small amounts of DOC. Another factor is the type of wood you are carving/cutting. Softer wood like pine will easily create fuzzies and burrs. Again, you could try to reduce the pass depth, or run a finish carve over the last the carve.

scottp55 Vectric Wizard Posts: 4801 Joined: Thu May 09, 2013 11:30 am Model of CNC Machine: ShopbotDesktop 5.5"Z/spindle/VCP12.* Scott, I took all your suggestions and I'm amazed at the lettering detail I'm getting on bad wood, can't wait till I can get some maple to work with. I faced the wood on my CNC, marked location and orientation of the piece in the jig. I then took the piece off the CNC and sanded down the face to finished grade. For example I can clamp boards at 45 degrees inside my CNC frame and use a simple end mill to mill off the end at 45 degrees relative to the board. You could use the moulding toolpath, but must be prepared to let the ball nosed bit cut into the spoilboard a little.

What is really exciting is ripping the chuck right off the spindle, or the toolpost. Just so everyone knows, people get killed regularly by lathes. Usually it is the piece coming off and smashing them in the head. And no, a face shield does not protect anyone from a 50lb piece of wood going about 100MPH hitting a person in the face.

I'm using V-Carve Dexktop 8.5 and a Shapeoko 3 XXL CNC with a 1/32nd ball nose mill. Even on large plaques certain letters do not carve well. It's very possible I'm trying to cut the letters too deep. I am currently using a 1/4" 60 degree V bit for inlays. I occasionally have tearout or chipping of the edges on my male parts. Often, these tearouts end up buried in the female part and cause no issues, but occasionally they do. Seems the harder the wood, the more prone it is to tear out. A recent piece of purpleheart was unusable due to the .

63a distribution box hire

6.75-in steel window box brackets

Cadrex is the foremost sheet metal manufacturer in North America, offering custom sheet metal fabrication services at strategically located facilities in the United States and Mexico. We provide our customers with the speed to scale required to quickly introduce new products into the market.

best cnc wood machines|c&c machine for woodworking