designing a box using sheet metal inventor 2019 I want to use Inventor to make a real sheet metal box. This box has a bottom, four sides, and folded over to the inside flanges along the four edges. Very standard. One of the most critical boxes is Box 1, labeled “Gross Distribution.” This box reports the total amount of money you withdrew from your HSA or MSA during the tax year, regardless of whether the distribution was for qualified medical expenses or other purposes.

0 · sheet metal simple box autodesk

1 · autodesk inventor sheet metal

2 · autocad inventor sheet metal

Location: Place junction boxes at strategic points where electrical connections are required, ensuring they are easily accessible for maintenance. Wiring: Follow electrical codes and guidelines when connecting wires within the junction box, ensuring a .

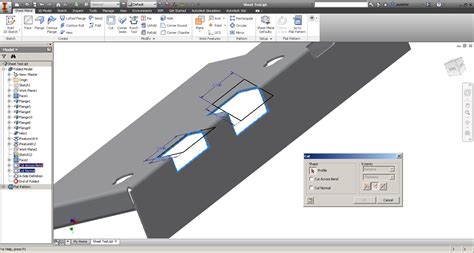

How to develop and fold sheet metal in Autodesk Inventor Sketch the lid, place it outside of the base. Then place a dimension of .25mm on each edge. So the lid is .25 mm outside the base. . I want to use Inventor to make a real sheet metal box. This box has a bottom, four sides, and folded over to the inside flanges along the four edges. Very standard. In this video we will create a box with the inventor's sheet metal module. If they want us to create another design, leave your comment in their section.

Apply the commands to sheet metal parts as well as standard parts and assemblies. Learn how to fold and unfold parts, create custom punches, K-Factors, Bend Tables, work with the Frame . I've modelled this box, and there must be a better sequence to follow than the one I used. How would you do it? What's the best route to get to this finished shape with better .

In this video, I demonstrate the creation of a sheet metal box that responds to changes in a single parameter (dimension) and automatically generates different .The Autodesk Inventor 2019: Sheet Metal Design student guide introduces the concepts and techniques of sheet metal modeling with the Autodesk Inventor software. The structure of the .

sheet metal simple box autodesk

Autodesk Inventor now has integrated sheet metal tools that make it easier to design with sheet metal. In this Inventor 101 video, we’ll take you through all of the sheet metal design basics you’ll need to know to get started .To set the parameters, click Sheet Metal > Setup > Sheet Metal Defaults on the ribbon; the Sheet Metal Defaults dialog appears. This dialog displays the default preferences of the sheet metal . How to develop and fold sheet metal in Autodesk Inventor

Sketch the lid, place it outside of the base. Then place a dimension of .25mm on each edge. So the lid is .25 mm outside the base. Create the face. Then when you place the flanges on the lid, it will always stay .25mm away from the base, even when you change size.

I want to use Inventor to make a real sheet metal box. This box has a bottom, four sides, and folded over to the inside flanges along the four edges. Very standard. In this video we will create a box with the inventor's sheet metal module. If they want us to create another design, leave your comment in their section.Apply the commands to sheet metal parts as well as standard parts and assemblies. Learn how to fold and unfold parts, create custom punches, K-Factors, Bend Tables, work with the Frame Generator, the Weldment environment, multi-body design methods, and much more! I've modelled this box, and there must be a better sequence to follow than the one I used. How would you do it? What's the best route to get to this finished shape with better reliefs?

In this video, I demonstrate the creation of a sheet metal box that responds to changes in a single parameter (dimension) and automatically generates different configurations of the box as the size increases or decreasesThe Autodesk Inventor 2019: Sheet Metal Design student guide introduces the concepts and techniques of sheet metal modeling with the Autodesk Inventor software. The structure of the student guide follows the typical stages of using the Autodesk Inventor software. Autodesk Inventor now has integrated sheet metal tools that make it easier to design with sheet metal. In this Inventor 101 video, we’ll take you through all of the sheet metal design basics you’ll need to know to get started with this type of material.

To set the parameters, click Sheet Metal > Setup > Sheet Metal Defaults on the ribbon; the Sheet Metal Defaults dialog appears. This dialog displays the default preferences of the sheet metal part such as sheet metal rule, thickness, material, and unfold rule. You can change these preferences as per your requirement. 2. How to develop and fold sheet metal in Autodesk Inventor Sketch the lid, place it outside of the base. Then place a dimension of .25mm on each edge. So the lid is .25 mm outside the base. Create the face. Then when you place the flanges on the lid, it will always stay .25mm away from the base, even when you change size.

I want to use Inventor to make a real sheet metal box. This box has a bottom, four sides, and folded over to the inside flanges along the four edges. Very standard.

In this video we will create a box with the inventor's sheet metal module. If they want us to create another design, leave your comment in their section.

Apply the commands to sheet metal parts as well as standard parts and assemblies. Learn how to fold and unfold parts, create custom punches, K-Factors, Bend Tables, work with the Frame Generator, the Weldment environment, multi-body design methods, and much more! I've modelled this box, and there must be a better sequence to follow than the one I used. How would you do it? What's the best route to get to this finished shape with better reliefs? In this video, I demonstrate the creation of a sheet metal box that responds to changes in a single parameter (dimension) and automatically generates different configurations of the box as the size increases or decreases

The Autodesk Inventor 2019: Sheet Metal Design student guide introduces the concepts and techniques of sheet metal modeling with the Autodesk Inventor software. The structure of the student guide follows the typical stages of using the Autodesk Inventor software. Autodesk Inventor now has integrated sheet metal tools that make it easier to design with sheet metal. In this Inventor 101 video, we’ll take you through all of the sheet metal design basics you’ll need to know to get started with this type of material.

autodesk inventor sheet metal

boxer metal parts

autocad inventor sheet metal

$14.99

designing a box using sheet metal inventor 2019|autodesk inventor sheet metal