build a cnc machine from scratch quotes Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine.

Our brand-new USA-made Wi-Fi ready plastic enclosures now feature specific design enhancements to help save you valuable time and money all while still providing a clean, centralized location for the home’s wired and wireless services.Read up on slot antenna's, and cut a hole in the conductive metal box of the appropriate size for the WiFi band of interest. (Hole can be weather sealed by something non .

0 · how to make a cnc machine

1 · how to build a cnc

2 · diy cnc milling machine

3 · diy cnc machine kit

4 · diy cnc machine

5 · diy cnc lathe machine

6 · build your own cnc machine

7 · build a cnc machine from scratch

Because WiFi does not penetrate metal walls, what is needed is the equivalent of an ethernet cable from one of the Orbi units inside the house to the Orbi satellite inside the .

how to make a cnc machine

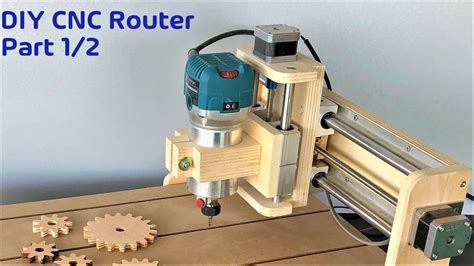

Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, .

This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal .

To build a CNC machine, it's essential to have a solid understanding of how they work. In this section, we will explain the basic principles of CNC machines, including the role of stepper .Building a CNC machine requires careful planning and design. In this section, we will discuss the essential components you'll need, such as stepper motors, controller boards, power supplies, .

Building a CNC Router: Need parts for your project? Check out my Amazon Affiliate link below, thanks!: http://amzn.to/2mVlbnl This instructable will show you how I built my CNC router. I hope you can draw some inspiration from my . Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine.Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. ThisThis Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine.

how to build a cnc

To build a CNC machine, it's essential to have a solid understanding of how they work. In this section, we will explain the basic principles of CNC machines, including the role of stepper motors, linear motion systems, and control software.Building a CNC machine requires careful planning and design. In this section, we will discuss the essential components you'll need, such as stepper motors, controller boards, power supplies, and more.Building a CNC Router: Need parts for your project? Check out my Amazon Affiliate link below, thanks!: http://amzn.to/2mVlbnl This instructable will show you how I built my CNC router. I hope you can draw some inspiration from my build and that this instructable will be h.

In this instructable, we'll be exploring how to build your own CNC (Computer Numerical Control) machine from scratch. With a CNC machine, you can automate the process of cutting, drilling, and carving various materials, such as wood, plastic, or metal, with high precision and repeatability.Learn the basics and follow my process to come up with your own CNC router design that meets your goals and budget. Follow my carefully engineered plans to build this high performing, affordable CNC router. Full set of detailed drawings, instructions, and Bill of Materials. Fastest path to ownership.In this blog post, we will walk you through the step-by-step process of building a CNC machine, starting from selecting the right components to assembling and programming the machine. So let's dive in! 1. Understanding CNC Machines: Before we begin the building process, it's crucial to have a clear understanding of CNC machines.

Explore the world of DIY CNC routers with our comprehensive guide. Learn how to build, optimize, and use your own CNC machine from scratch.

Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine.Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. ThisThis Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine.

To build a CNC machine, it's essential to have a solid understanding of how they work. In this section, we will explain the basic principles of CNC machines, including the role of stepper motors, linear motion systems, and control software.Building a CNC machine requires careful planning and design. In this section, we will discuss the essential components you'll need, such as stepper motors, controller boards, power supplies, and more.

Building a CNC Router: Need parts for your project? Check out my Amazon Affiliate link below, thanks!: http://amzn.to/2mVlbnl This instructable will show you how I built my CNC router. I hope you can draw some inspiration from my build and that this instructable will be h.In this instructable, we'll be exploring how to build your own CNC (Computer Numerical Control) machine from scratch. With a CNC machine, you can automate the process of cutting, drilling, and carving various materials, such as wood, plastic, or metal, with high precision and repeatability.

Learn the basics and follow my process to come up with your own CNC router design that meets your goals and budget. Follow my carefully engineered plans to build this high performing, affordable CNC router. Full set of detailed drawings, instructions, and Bill of Materials. Fastest path to ownership.

diy cnc milling machine

In this blog post, we will walk you through the step-by-step process of building a CNC machine, starting from selecting the right components to assembling and programming the machine. So let's dive in! 1. Understanding CNC Machines: Before we begin the building process, it's crucial to have a clear understanding of CNC machines.

diy cnc machine kit

how to cap loose wires in junction box

Tracki works in 185 countries. Tracki comes with a built-in SIM and the device is working out-of-the-box within 5 minutes. No need for a local SIM card and you cannot change the SIM. It will work anywhere that you have a GSM cellular signal. What is GPS?Do not use sheet-metal screws. However, this may not be necessary. The device has metal tabs (ears) where you screw it into the box. Pay close attention - if the ears "bottom out" on the metal of the box, you do not .

build a cnc machine from scratch quotes|diy cnc machine