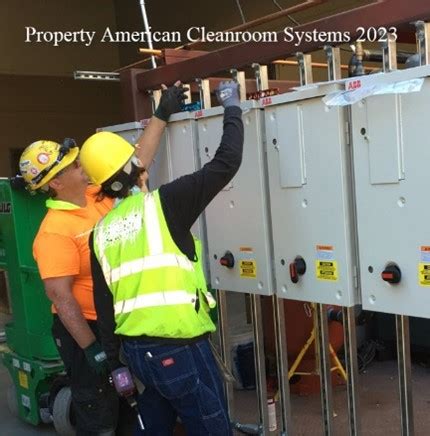

clean room electrical boxes We offer cleanrooms with the industry’s highest quality design to meet most cleanliness levels – from Class 10 to 100,000 and USP 797 – using the most cost-effective combination of construction materials. CNC, or Computer Numerical Control, machines utilize computerized programming to automate the movement of tools and machinery, enhancing precision and efficiency in manufacturing. .

0 · electrical considerations for cleanrooms

1 · cleanroom electrical

The light cord wires run in conduit (pipe) from the back of the light niche, to the junction box where the wires connect to the wires coming from the GFCI breaker. The junction box should be 18" above the water level, to keep pool water out.

We provide accessories and attachments for cleanroom systems. Support posts, electrical and monitoring systems complete your clean room installation. In addition, we offer a wide variety of anti-static vinyls, softwall curtains and .Discover our cleanroom pass through box range using HEPA-purge cycles for contamination control. Explore our pass boxes here.Choose from our selection of clean room boxes, including corrosion-resistant washdown enclosures, cardboard boxes, and more. In stock and ready to ship.

We offer cleanrooms with the industry’s highest quality design to meet most cleanliness levels – from Class 10 to 100,000 and USP 797 – using the most cost-effective combination of construction materials.

Terra Universal is the leading manufacturer of critical environment applications, with over 45 years of design and fabrication experience in cleanroom and laboratory-based industries. Terra manufactures comprehensive lines of .A comprehensive list of equipment going into the cleanroom along with electrical voltage and current requirements for each piece of equipment is critical to a good cleanroom electrical design. OSHA recommends that permanent equipment be hardwired.

We provide accessories and attachments for cleanroom systems. Support posts, electrical and monitoring systems complete your clean room installation. In addition, we offer a wide variety of anti-static vinyls, softwall curtains and strips, polypropylene sheets and aluminum framing options.

Electrical. The selection of the best methods or systems for electrical systems required for your Cleanroom can vary with the requirements. We can help you understand the various systems available, and choose the best solution for your project.Discover our cleanroom pass through box range using HEPA-purge cycles for contamination control. Explore our pass boxes here.Choose from our selection of clean room boxes, including corrosion-resistant washdown enclosures, cardboard boxes, and more. In stock and ready to ship.

We offer cleanrooms with the industry’s highest quality design to meet most cleanliness levels – from Class 10 to 100,000 and USP 797 – using the most cost-effective combination of construction materials.Terra Universal is the leading manufacturer of critical environment applications, with over 45 years of design and fabrication experience in cleanroom and laboratory-based industries. Terra manufactures comprehensive lines of modular cleanrooms, pass-through chambers, desiccator cabinets, glove boxes, laminar flow benches and furnishings.Mecart’s clean room wall panels are insulated (R-16 insulation) for easier climate control, energy savings and a better acoustical performance. Get a state-of-the-art, long-term asset that exceeds your requirements and expectations.

Are there any special clean room requirements for a Class 10,000 clean room where we are installing receptacles, conduit and wire? I have heard that you never want to put panelboards in a clean room, and that there are obviously clean room rated lighting fixtures. Discover cleanroom electrical maintenance tips, best practices, and the role of electrical systems in maintaining a sterile, airtight environment.A comprehensive list of equipment going into the cleanroom along with electrical voltage and current requirements for each piece of equipment is critical to a good cleanroom electrical design. OSHA recommends that permanent equipment be hardwired.

We provide accessories and attachments for cleanroom systems. Support posts, electrical and monitoring systems complete your clean room installation. In addition, we offer a wide variety of anti-static vinyls, softwall curtains and strips, polypropylene sheets and aluminum framing options.Electrical. The selection of the best methods or systems for electrical systems required for your Cleanroom can vary with the requirements. We can help you understand the various systems available, and choose the best solution for your project.

Discover our cleanroom pass through box range using HEPA-purge cycles for contamination control. Explore our pass boxes here.Choose from our selection of clean room boxes, including corrosion-resistant washdown enclosures, cardboard boxes, and more. In stock and ready to ship.We offer cleanrooms with the industry’s highest quality design to meet most cleanliness levels – from Class 10 to 100,000 and USP 797 – using the most cost-effective combination of construction materials.Terra Universal is the leading manufacturer of critical environment applications, with over 45 years of design and fabrication experience in cleanroom and laboratory-based industries. Terra manufactures comprehensive lines of modular cleanrooms, pass-through chambers, desiccator cabinets, glove boxes, laminar flow benches and furnishings.

Mecart’s clean room wall panels are insulated (R-16 insulation) for easier climate control, energy savings and a better acoustical performance. Get a state-of-the-art, long-term asset that exceeds your requirements and expectations. Are there any special clean room requirements for a Class 10,000 clean room where we are installing receptacles, conduit and wire? I have heard that you never want to put panelboards in a clean room, and that there are obviously clean room rated lighting fixtures.

electrical considerations for cleanrooms

cleanroom electrical

Fabricated metal products come in various shapes and sizes, including sheets, plates, bars, pipes, and tubes. They are customized to fit specific requirements. The most common metal materials used in fabrication are aluminum, .

clean room electrical boxes|cleanroom electrical