sheet metal bending bar There are lots of different paths to find your way around a bend, by using either the included or complementary angles. We can easily calculate these values; it is the applicationof the . See more One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing valuable insights for DIY enthusiasts.

0 · solid steel round bar bender

1 · sheet metal bending allowance chart

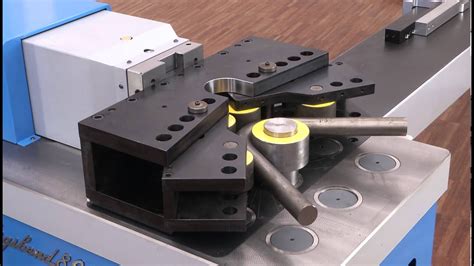

2 · machine for bending steel bar

3 · best steel rod for bending

4 · bending stainless steel flat bar

5 · bending metal rods by hand

6 · bending flat bar 90 degrees

7 · basics of bar bending schedule

USS Gold Star metal boxCondition: It is in Used Condition showing some light normal use.Description: This is a very nice vintage WWII metal box noting the USS Gold Star. It will come exactly as shown..from

Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary The length of the neutral axis is calculated as a bend allowance, taken at 50 percent of the material thickness. In Machinery’s Handbook,the K-factor for mild cold-rolled steel . See moreThere are two basic ways to lay out a flat blank, and which to use will depend on the information that you are given to work with. For the first method, . See more

There are lots of different paths to find your way around a bend, by using either the included or complementary angles. We can easily calculate these values; it is the applicationof the . See more Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum. Learn how to accurately calculate bend allowance with our easy-to-understand formula. Improve your sheet metal bending operations and achieve precise results every time.

How sheet metal bends, k factor, bend allowance explained and more. This video includes drawings, animations, formulas and press brake bends.It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet .

Max Weiss can perform bending on all types of metal for all your custom metal and steel bending needs. Inquire now! About; News; Resources; . Bar Bending. We bend round, half-round, square, hexagonal and rectangular (flat) bars into rings and ring segments. . Alloy Steel Aluminum Brass Carbon Alloys Copper Sheet Metal Stainless Steel. Max .Folding bars are a tool / piece of equipment, for working with sheet metal. They are placed in a vice and used to ‘fold’ the sheet metal, to a 90 degree angle. . ‘Folding’ is the correct term for bending or forming sheet metal to an angle. .Shape sheet metal using your bench vise as a sturdy base. Remove or slide the four dies along the clamping bar to form angles, channels, boxes, trays, and pans in a variety of widths. Unlike bench-top and floor-mount benders, these are not permanently mounted— pull them out when you need them and store them when you don’t.

VEVOR YP-9 Manual Bender, 1” - 2“ High Capacity Round Square Bar Metal Bender with 7 Bending Dies, Metal Rod Bar Bender Bending Tool for Construction Site Auto Repair KAKA INDUSTRIAL PR-3 Ring Roll Bender, 3inch Manual Roll Bender,Manual Sheet Steel Ring Roll Bender up to 1/4" round bar and 1" x 3/16" flat bar, easy to operate.

solid steel round bar bender

Sheet Metal Bending Calculator. Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal bending operations. This advanced calculator provides key insights into:Malco’s 12F, 18F, and 24F Sheet Metal Folding Tools offer a premium choice for bending and forming metal. Each model is made with superior design and includes handy sight holes to ensure proper depth alignment. Whether you are an HVAC or roofing pro, Malco offers you the right tool to get the job done.12 Inch Sheet Metal Folding Tool - Ultimate HVAC Sheet Metal Bender, Hand Seamer, Metal Forming Tool for Duct Work & Metal Roofing; Premier Sheet Metal Folding Bar & Bending Tool for Professionals 4.1 out of 5 starsKlein Tools 86532 Metal Folding Tool for Duct Bending 18 x 3-Inch Folds Up to 24 ga CRSM and 28 ga Stainless - Amazon.com. . SDSNTE 24 In 16 Ga Steel Sheet Metal Folding Tool with Grips for Creating Uniform Folds Fits HVAC Applications and Pipefitter, Red, Pack of 1.

Make smooth, precise bends in sheet metal up to 36 in. wide. The adjustable press plate lets you make sharp or round bends up to 0 - 120°. Rugged all-steel construction. Comes with a sturdy wide-base stand that is pre-drilled for bolting to your shop floor. Bends metal up to 36 in. wide; Makes bends to 0 - 120°Sheet Metal Brake: A sheet metal brake is a hand-operated tool that clamps the sheet metal between a bending plate and a clamping bar, allowing the user to apply force and create the desired bend. Seaming Pliers: These pliers have broad, flat jaws designed to grip and bend sheet metal along a straight edge, making them ideal for creating seams .

30" Steel Bending Brake Our 30" Sheet Metal Bending Brake is perfect for bench top use. This brake features: High quality steel construction, Easily makes up to 90 degree bends, Bends material up to 30", Bends material up to 17 gauge mild sheet steel, Designed for bench top mounting or mount using "C" clamps . Also, the steel bar that holds .

How sheet metal bends, k factor, bend allowance explained and more. This video includes drawings, animations, formulas and press brake bends.More On K Facto.Bend Radius - As a rule, inside bend radius should be equal to material thickness. When the radius is less than recommended, this can cause material flow problems in soft material and fracturing in hard material. Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part.VEVOR Box and Pan Brake, 48-Inch, 0-130 Degrees Sheet Metal Bending Brake, Portable Mini Metal Bender with 20 Gauge Low Carbon Steel 14 Gauge Aluminum Capacity Power Handle, for Metal Bending. 3.6 out of 5 stars. 24. 0.21 $ 160. 21. FREE delivery Thu, Nov 14 . Add to cart-Remove. Overall Pick. Your part is in the sheet metal environment, which is intended to work with uniform thickness materials (sheet metal, for instance). The Bend tool is in the normal modeling environment, and if you change over to that .

BAR BENDING MACHINE - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document provides guidelines for safely operating a bar bending machine. It lists 10 pre-operational guidelines including ensuring . This article dives into the essential techniques and precautions for Z and N bending in sheet metal fabrication. You’ll learn about critical procedures, positioning principles, and special processing methods to ensure accurate and .Torsion Bar Nc Press Brake Plate Bending Machine Sheet Metal Folding Factory Price, Find Details and Price about Bending Machine Nc Press Brake from Torsion Bar Nc Press Brake Plate Bending Machine Sheet Metal Folding Factory Price - Guangdong GSI Elevator Electromechanical Equipment Ltd . Torsion Bar Nc Press Brake Plate Bending Machine .Mini Metal Sheet Brake: Max. Bending width: 36 inches/910 mm; Max. Bending thickness: 0.04 inches/1 mm. Our metal sheet brake is a great tool to bend your metal sheets, with its extraordinary bending performance making itself quite a .

Sheet Metal Bending By- Prem Mahendranathan . BENDING ! Bending is a manufacturing process by which a metal can be deformed by . Prem Mahendranathan . PROFILES Prem Mahendranathan . BAR FOLDER ! Making bends or folds along the edges ! For folding small hems, flanges.. ! Set the machine before use Prem Mahendranathan . FLANGE . Brake Sheet Metal Tools 0-135° Degrees Sheet Metal Bending Brake Heavy Duty Sheet Metal Bender 24-Inch Bending Machine 1 offer from 577 $ 435 77 Greenlee EK50ML13811 Micro Crimping Tool Kit with 13.8mm JAW, 110V

Column 1: S = Sheet metal thickness; Column 2: A = flattening height; Column 3: Necessary force per metre to flatten sheet metal with 450N/mm 2 tensile strength (mild steel), 1 T = 9.8 KN; Column 4: flatten sheet metal with 700N/mm 2 tensile strength (stainless steel); There are four primary hemming bending solutions designed to accommodate various bending . VEVOR Box and Pan Brake, 24-Inch, 0-130 Degrees Sheet Metal Bending Brake, Portable Metal Bender with 20 Gauge Low Carbon Steel 14 Gauge Aluminum Capacity, 5 Adjustable Fingers for Metal Bending. dummy.This is 1” x 4” flat bar rolled to 180 degrees, making a U-bend. Rolling flat bar is one of our specialties at Jorgenson Metal Rolling & Forming, we also do heavy duty plate rolling to make things like pipe collars, pipe supports, pipe saddles, . Additional, this sheet metal bender can bend to 90 degrees by simply turing handle level until the desired angle is accomplished. . KAKA INDUSTRIAL PR-3 Ring Roll Bender, 3inch Manual Roll Bender,Manual Sheet Steel Ring Roll Bender up to 1/4" round bar and 1" x 3/16" flat bar, easy to operate. .

Bending and forming sheet metal is a process that is used to create duct work as well as metal enclosures such as electrical boxes. If you are looking for a metal manufacturer that can take care of all of your sheet metal bending and forming services, ABT Metals has your back! Our team of knowledgeable and professional engineers and technicians will work with you to help you . The folding of sheet metal is carried out using a cornice brake or a bar folder, and it comprises a clamping beam that helps to bend the metal sheet and achieve the desired shape. The metal sheet is bent in a V-shape with a positive or a negative angle.

sheet metal bending allowance chart

Utility Distribution Boxes (UDBs) provide safe power distribution in applications requiring feed-thru to larger areas; Advanced Mobile Electric Power Distribution System (AMEPDIS) is a digitally controlled, highly ruggedized power distribution unit

sheet metal bending bar|basics of bar bending schedule