programmable manufacturing automation cnc machine tools Programmable automatic bandsaw with intelligent CNC performance CNC-530 is a high-end machine developed for cutting hard materials with tungsten carbide sawbands. Hard materials like Inconel, Titanium, and Stainless Steel are . An underground electrical pull box provides another access point in long runs of cable to make it easier to pull the conductors from one end of the run to the other.

0 · what is programmable automation

1 · programmable automation process

2 · numerical control machine parts

3 · numerical control machine

4 · milling machine cnc systems

5 · cnc machine tool systems

6 · best cnc for machine tools

7 · automated cnc machine tools

Reflective material refers to fabric that’s built to reflect sunlight, UV light, or any light that falls on it back to the eye of the observer. Such material is built for increasing the visibility of the wearer and is typically used on safety wear clothing, athletic or casual wear.

what is programmable automation

This blog post will explore the key aspects of programmable manufacturing automation within CNC machine tools, touching on their benefits, the future prospect, and the optimization of . Programmable automation utilizes an assortment of CNC (Computer Numerical Controlled) machine tools, industrial robotic applications .Programmable automatic bandsaw with intelligent CNC performance CNC-530 is a high-end machine developed for cutting hard materials with tungsten carbide sawbands. Hard materials like Inconel, Titanium, and Stainless Steel are . Numerical control (NC), commonly known as computer numerical control (CNC), is a technology that allows the automation of machine tools. It uses programmable machine controller units and software to efficiently produce .

Study with Quizlet and memorize flashcards containing terms like Originally, the field of mechatronics was intended to be a combination of __________., CNC (Computer Numerical Control) refers specifically to a computer that controls what aspect of the machine?, VFDs have become so inexpensive that they are replacing __________ for many constant-speed .defined here, programmable automation in-cludes computer-aided design (CAD); comput-er-aided manufacturing tools—e.g., robotics, numerically controlled (NC) machine tools, flexible manufacturing systems (FMS), and automated materials handling (AMH); and computer-aided techniques for management— e.g., management information systems (MIS)1. What is a Programmable CNC Machine? A Programmable CNC (Computer Numerical Control) machine is a sophisticated piece of equipment used in manufacturing processes. It is capable of automatically executing pre-programmed instructions to control the movement and actions of various cutting tools or drills.

The three basic types of automated systems used in manufacturing are fixed automation, programmable automation, and flexible automation. . A CNC machine can be designed with have multiple axes. Conventionally we consider the X, Y, and Z axes as the primary axes. . The three basic types of automated systems used in manufacturing are fixed . Mitsubishi Electric Automation, Inc. to Celebrate 50 Years of Supporting the Machine Tool Industry in North America at IMTS 2024 . Mitsubishi Electric Automation, Inc. is celebrating 50 Years of “The Difference in Your Machining” at the International Manufacturing Technology Show (IMTS) from Sept. 9-14 in Chicago.One crucial element of CNC machine automation is the use of programmable logic controllers (PLCs). In this blog post, we will explore the significance of PLC control in CNC machines and how it enhances their performance and functionality. Introduction to CNC Machines and PLC Control . CNC machines are computer-controlled systems that use pre . For individual machine automation, CNC is generally preferred. Where PLC is used, it does better with specialized machine tools that regularly perform the same task. PLC in action – the Summit HBM-110H. Boring mills, like Summit’s HBM 110H, are a good example of the utility of PLC for high-end machine tools.

Fixed Automation- The sequence of processing (or assembly) operations is fixed by the equipment configuration Programable automation- It is designed with the capability to change the sequence of operations to accommodate different product configurations. Flexible automation- •An extension of programmable automation in which the system is capable of changing over from .Directory. CNC’s directory of Resources, join together all of the companies, and associations that are useful to individuals concerned with finding information about CNC’s (computer numerical control) & NC, PLC’s (programmable logic controller), Machining companies, Robotics, Factory Automation from scada to complete project planning, installation and management.Programmable automation utilizes an assortment of CNC (Computer Numerical Controlled) machine tools, industrial robotic applications and programmable logic controllers (PLC) that work in real time. Operational efficiency is accomplished through the application of logical programming commands with automation technologies that power equipment and .

In order to minimise tool change times, CNC machines are fitted with automatic tool changers that are also being pushed to the limit of performance. Currently, machine tools offer tool-to-tool time (tool changing time) within 10 s. In addition, the automatic pallet changer that comes as an additional feature on CNC machines is designed to . One of the most significant benefits of CNC is the automation of the manufacturing process. CNC machines can run 24/7, increasing productivity and reducing production time. Additionally, CNC is highly accurate, allowing for tight tolerances, precise cuts and holes, and consistent quality. Programmable Logic Control (PLC)

CNC Machines (1442) CNC Mill (798) Vertical Machining Center (646) CNC Lathe . The Mazak HV630's capacity to handle diverse materials and its strong automation features make it a powerful tool for modern manufacturing needs. . high-speed spindle options, and automation packages for increased productivity. Mazak HV630 Estimated New Price .

The Mikron X400-U facilitates the manufacturing of components with intricate geometries and stringent tolerances. It is well-suited for both high-volume and specialized production runs, leveraging its advanced features for optimal results. . The Mikron X400-U is a CNC milling machine known for its precision and adaptability across several .

Manufacturing processes -- Automation, Machine-tools -- Numerical control -- Programming, Robots, Industrial -- Programming, Programmable controllers Publisher New York, N.Y. : Industrial Press .

Bear Technology Group specializes in onsite retrofitting and rebuilding of all types of machine tool equipment. Retrofitting with newer style PLC's and CNC controls can greatly improve the efficiency, repeatability, and accuracy of your existing equipment, but without the large capital expense of purchasing new machine tools. Mitsubishi Electric Corporation, established in 1921, stands as a global leader in motor products and industrial automation solutions. With a workforce exceeding 100,000 employees worldwide, this Fortune Global 500 enterprise has consistently demonstrated its commitment to technological innovation and manufacturing excellence. Here, we delve into some common types of the automation tools used in the manufacturing sector. 1. Robotic Automation . CNC machines use computerized controls to operate and manipulate machine tools, including grinders, mills, and lathes. . Programmable Automation can perform several functions, producing multiple item types in a shorter .CNC Machines (1442) CNC Mill (798) Vertical Machining Center (646) CNC Lathe (498) Horizontal Machining Center (139) . The AL 303 is capable of producing engine parts and specialized tools efficiently. Its design enhances productivity, supporting a range of materials to meet industrial demands. . and automation integration. These .

Discover RoboWrench X5, the first fully programmable 5-axis CNC pneumatic vise. Engineered for unmatched precision and versatility, it integrates seamlessly with 5-axis CNC machines, offering infinite rotation and fully customizable jaw positioning. Perfect for automating complex tasks, RoboWrench X

programmable automation process

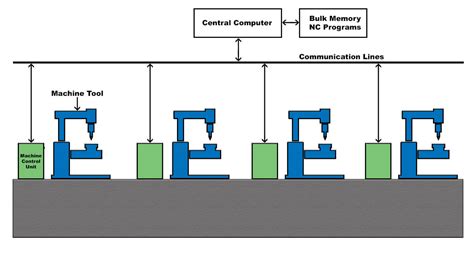

In 1996 Artran merged with Vector Inc., a PC-based, open-architecture machine tool control manufacturing company. Over the next year Artran increasingly redirected its vision toward the CNC machine tool market. By 1997 the company was completely focused on its own CNC control, the Contour, and its growing line of machine tools.In the 1970s, computer numerically controlled (CNC) machine tools were developed with minicomputers used as control units. With the advances in electronics and computer technology, current CNC systems use several high-performance microprocessors and programmable logical controllers that work in a parallel and coordinated fashion.

Numerical control (NC) is one of the greatest innovations in the achievement of machine tool automation in manufacturing. In this chapter, first a history of the development up to the advent of NC machine tools is briefly reviewed (Sect. 35.2).Then the machining centers and the turning centers are described with their key modules and integration into flexible .Manufacturing Robots. An automation system from Mills CNC can range from Doosan Collaborative Robots, . Machine Tool Automation. Mills CNC Automation Services. . programmable and capable of movement on three or more axes. Typical applications include machine tending, welding, painting, assembly, disassembly, pick and place operations .Rottler Manufacturing is the world's leading maker of CNC machines, software, and accessories for engine building, remanufacturing and OEM machine tools.

dominique perrault metal mesh or fabric ceiling

Galvanization (commonly referred to as galvanized) is a protective zinc coating applied to a steel or iron substrate through a hot-dip galvanizing process. Galvanized metals are used in many different industries for a range of products. For example, you can find galvanized steel used to make:Galvanizing, or galvanization, is a manufacturing process where a coating of zinc is applied to steel or iron to offer protection and prevent rusting. There are several galvanizing processes available, but the most commonly offered and used method is called hot-dip galvanizing.

programmable manufacturing automation cnc machine tools|automated cnc machine tools