sheet metal fabrication meaning Definition: Sheet metal is a flat, thin piece of metal formed through an industrial process. It’s characterized by its high surface area to volume ratio, which allows it to be bent, cut, and shaped into various forms. For example, metal bed frames are better for those that prioritize affordability and low maintenance, while wooden bed frames offer more versatility and sustainability. Plus, other elements influence your choice of bed frame materials. That includes capacity for support, noisiness, adjustability, assembly, safety, and design options.

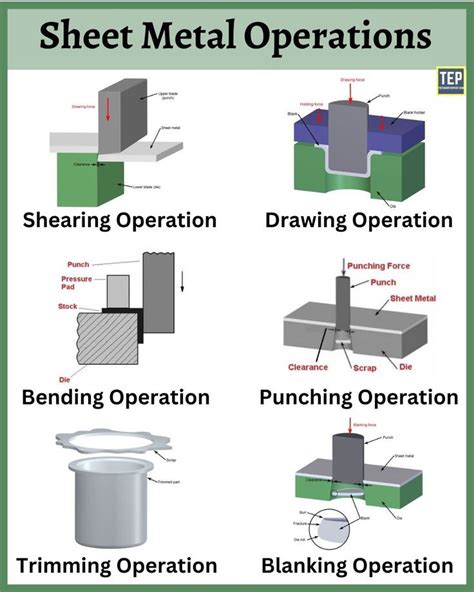

0 · various sheet metal processes

1 · types of sheet metal process

2 · types of sheet metal fabrication

3 · sheet metal manufacturing process types

4 · sheet metal manufacturing guide

5 · how to fabricate sheet metal

6 · how is sheet metal manufactured

7 · basics of sheet metal fabrication

CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or Computer Aided Design (CAD) software like .

Sheet metal fabrication is the process of turning flat sheets of steel, aluminum, titanium or other metals into metal structures or products. This transformation is achieved through a series of techniques such as cutting, .Sheet metal fabrication is a process of working with metal, used in various industries, ranging from construction and automotive to warehouse and electronics. It involves transforming flat sheets of metal into functional .

Definition: Sheet metal is a flat, thin piece of metal formed through an industrial process. It’s characterized by its high surface area to volume ratio, which allows it to be bent, cut, and shaped into various forms. Sheet metal fabrication refers to the turning of flat metal sheets into metal products and structures. Typically, this technique involves transforming different types of sheet metals .Sheet metal fabrication is the process of turning flat sheets of steel or aluminium into metal structures or products, by cutting, punching, folding and assembling. Sheet metal can be cut, bent or stretched into nearly any shape, which is .

What is sheet metal fabrication, exactly? It’s the process of transforming flat sheets of metal — like aluminum, steel or stainless steel — into desired shapes and forms. It involves a combination of cutting, bending, . Sheet metal fabrication is a manufacturing process that involves converting sheet metal into equipment parts and products. This technique is used across industries to produce components for machinery, vehicles, appliances . The definition of metal fabrication and types of fabricated products. As a process, metal fabrication is all about creating various metal structures using different processes using .Sheet metal fabricating is a service performed in the manufacturing industry that involves the creation of metal parts and components through cutting, bending, and shaping sheets of .

The fundamentals of sheet metal fabrication will be discussed in this piece. We will shed some light on this method of producing metal, which has many applications across different sectors. . Fabricating objects and . 12 Top Sheet Metal Fabrication Terms FAQ. 12.0.1 What does DFM stand for, and why is it important in sheet metal fabrication? 12.0.2 What is oil canning, and how can it be prevented in sheet metal parts? 12.0.3 How do I .

The significance of sheet metal fabrication extends across various industries, from automobile and construction to aerospace and energy. Essentially, What is sheet metal fabrication? It is the technique of sheet metal . Fabrication Meaning Fabrication refers to the process of creating products or components by assembling, shaping, or manipulating raw materials. . It’s more fascinating than you might think, and I’m here to break it down. Sheet metal fabrication is the process of transforming flat sheets of metal into specific shapes and structures through . Metal Fabrication Definition. Metal fabrication is the process of converting unfinished metal components or products into completed goods using a variety of methods, including cutting, bending, welding, and assembly. Metals are shaped and manipulated into desired shapes using specialized equipment and tools.

Understanding the nitty-gritty of tolerances in sheet metal fabrication is like holding the cheat sheet to a successful project. Whether you’re wrestling with wall thickness, nominal dimensions, or the mean value of a cross-section, getting the tolerance range right is crucial. The original definition of tolerance is the way of limit definition, which can not describe a distribution well. Two parameters are required to describe a distribution, mean value and standard deviation. . Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. To achieve the .

What is sheet metal punching? Definition and Concept. Sheet metal punching, or subtractive manufacturing, creates holes, slots, or shapes by applying a mechanical punch through sheet metal. . I have over ten years of professional experience in sheet metal fabrication, specializing in laser cutting, bending, welding, and surface treatment . Sheet metal stamping is also a process that can be controlled as dimensional changes could be predicted based on die life time studies. The short term capability is very good but the long term looks horible because of die wear. The process variation is fairly small and one of the biggest factors is variation in sheet metal thickness. Sheet Metal fabrication is a manufacturing process where flat sheets of steel o. In this video, you'll learn what sheet metal fabrication is and how it works. Sheet Metal fabrication is a .

various sheet metal processes

Sheet metal fabrication is the process of transforming flat sheets of metal into specific shapes and structures through cutting, bending, and assembling techniques. It’s a crucial method in manufacturing, widely used across industries such as construction, automotive, aerospace, and electronics, to create durable and precisely engineered .In the broadest sense, sheet metal fabrication refers to the process of creating metal structures using various techniques including cutting, bending and assembly. August 2017. . The definition of fabrication specifically applies to the three processes described above. Other seemingly similar processes such as machining and stamping will .

18 x 24 electrical in ground pull box

Basics of Sheet Metal Dimensions Definition of tolerances in sheet metal fabrication. Tolerances are at the core of all our sheet metal fabrication work. What exactly are tolerances? Tolerances are the acceptable range of variations in the dimensions of sheet metal parts that we manufacture. Sheet metal’s recyclability also makes it a sustainable choice, further contributing to its long-term value and reducing waste in manufacturing processes. Challenges to Consider in Sheet Metal Fabrication. While sheet metal fabrication offers numerous advantages, it’s important to recognize the challenges that can arise. Understanding these .

This article will delve into the definition, processes, types of techniques, material selection, surface treatment options, design considerations, and DfM techniques in sheet metal fabrication, and explore why top-tier sheet . Welcome to our in-depth exploration of sheet metal fabrication. One may wonder, "what is sheet metal fabrication?" At its core, it's a collection of processes that manipulate sheet metal into different shapes and structures. By . Discover the meaning and definition of fabrication, with clear examples showcasing its importance in manufacturing and construction processes. . 2- Sheet Metal Fabrication: This involves cutting and shaping metal sheets into desired forms for various applications, such as HVAC systems, automotive parts, and appliance enclosures. . Bronze: This metal has high ductility, meaning it’s less likely to crack or break while you’re working with it. Copper: . Sheet metal fabrication is also convenient and cost-effective. It’s an affordable way to design and mass-produce high-quality products. And because of their light weight, sheet metal products are easier and less .

Definition of Fabrication in Construction. . Sheet Metal Fabrication: Sheet metal fabrication refers to the creation of components from thin metal sheets, such as steel, aluminum, or copper. This process involves cutting, bending, welding, and assembling the metal sheets to produce various components, including ductwork, enclosures, and . Metal Fabrication Categories. Let’s explore the four main categories of metal fabrication. Structural Fabrication. Structural fabrication is a specialized sub-category of metal fabrication that focuses on the creation of large-scale structural components and assemblies used in various industries, including construction, manufacturing, and infrastructure development. Practical issues for sheet metal fabrication. A number of important characteristics of a sheet metal product cannot yet be universally recorded in the STEP AP242 protocol. Dutch consultant Ton Derksen has conducted extensive research and concluded the following list of missing features. A STEP AP242 file cannot support standardized .Get an overview to sheet metal fabrication from the different types of sheet metal fabrication, to design best practices, materials, finishings and fastenings. 20% off your first order. Save up to ,000/€1,000. Ends 30 Nov 2024. . Inconsistent bend orientations and varying bend radii mean the part will be need to be reoriented more often .

Sheet Metal Fabrication: Sheet metal fabrication involves forming and manipulating thin sheets of metal, commonly used in various industries. HVAC Systems: Crafting ductwork and other components for heating, ventilation, and air conditioning systems. Automotive Parts: Manufacturing body panels, frames, and other parts for vehicles.In our last blog, Metal Construction Industry 101 looked at the fundamentals along with the current and emerging trends. Continuing the conversation now with metal fabrication, another key fundamental process in the metal construction industry. Globally it is valued at over 20 billion in 2022 and poised to grow to over 31 billion by 2031!. The metal fabrication industry is an .

My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals. I am constantly thinking, reading, and writing about these subjects, constantly striving to stay at the forefront of my field. Let my knowledge and expertise be an asset to your .

Sheet metal fabrication is an essential process for many industries, enabling the creation of complex and precise metal components. Understanding the various fabrication techniques is crucial for effective decision-making, cost optimization, and quality control. In this guide, we’ll explore the key sheet metal fabrication techniques, their .Meaning of Fabrication in Tamil language with definitions, examples, antonym, synonym. தமிழில் அர்த்தம் படிக்கவும். . 4. the sheet metal fabrication industry is closely related to our daily life. 1. 5. எஃகு உற்பத்தி பட்டறைகள். 5. steel fabrication .

types of sheet metal process

types of sheet metal fabrication

The industry standard for two-coat stucco underlayment, at least on the West Coast, is two layers of Grade D building paper. It’s also acceptable to place one layer of Grade D building paper or asphalt felt over a layer of Tyvek.

sheet metal fabrication meaning|sheet metal manufacturing guide