aluminum fabrication process Aluminum fabrication is an important manufacturing process you can use to make many parts. Whether you want to make aluminum profiles, aluminum enclosures, or aluminum automotive parts – you will adopt efficient .

Jun 30, 2023 - Explore Beth Ellis's board "white house metal roof" on Pinterest. See more ideas about house exterior, farmhouse exterior, house design.

0 · where does aluminium come from

1 · when was aluminum first made

2 · how is aluminum produced

3 · how is aluminum obtained

4 · how is aluminium made simple

5 · how is aluminium currently produced

6 · how do you mine aluminum

7 · aluminium manufacturing process flow chart

Metal roofs offer some compelling advantages over traditional roofing materials, including a unique blend of style and durability. But are they worth the investment? We’ll break down the pros and cons of metal roofs to help you make an informed decision.

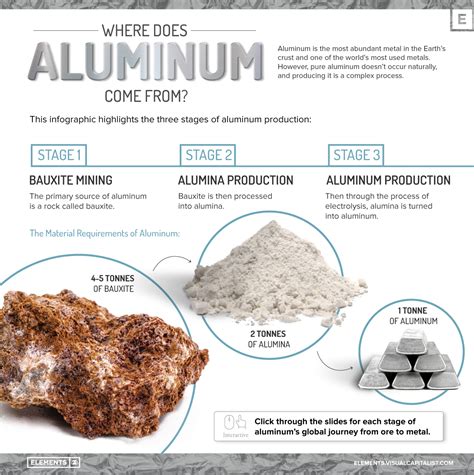

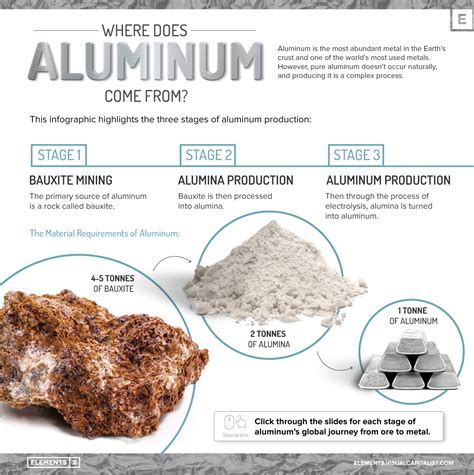

In general, the aluminum-making process involves three steps: mining for bauxite, extracting alumina from the mined bauxite and turning the alumina into aluminum. In this guide, we’ll look at each step of the aluminum production process from .Primary production involves mining bauxite deposits from the earth, chemically refining it into pure aluminum oxide and performing electrometallurgical processing to ultimately form aluminum. Secondary production makes new . Aluminium fabrication is the process of creating custom aluminum products. This can be done through a variety of methods, including welding, bending, and cutting. Aluminium fabrication is used in a variety of industries, .Major types of aluminum processing include: Casting is the original and most widely used method of forming aluminum into products. Technical advances have been made, but the principle .

Our guide will walk you through the entire process of how aluminium is made, from extracting the raw materials to turning it into the finished product. Aluminum fabrication is an important manufacturing process you can use to make many parts. Whether you want to make aluminum profiles, aluminum enclosures, or aluminum automotive parts – you will adopt efficient .

The art of aluminum fabrication involves aluminum bending, cutting, and assembling to create various products. This is an art-science combination that requires both advanced machines and skilled workers. Aluminum fabrication is the process of transforming raw aluminum into components, parts, or end products through various techniques and methods. This process involves . In the simplest terms, aluminum fabrication is the process of shaping aluminum into a finished design or product. From intricate aerospace parts to everyday household items — aluminum fabrication can do it all. Its . Beginning with bauxite extraction, we explore the transformation into alumina via the Bayer process, and subsequent conversion into aluminum through the Hall-Héroult .

In general, the aluminum-making process involves three steps: mining for bauxite, extracting alumina from the mined bauxite and turning the alumina into aluminum. In this guide, we’ll look at each step of the aluminum production process from .Primary production involves mining bauxite deposits from the earth, chemically refining it into pure aluminum oxide and performing electrometallurgical processing to ultimately form aluminum. Secondary production makes new aluminum from recycled scrap that for many products, like cans, is completely suitable for the same high quality.Aluminium fabrication is the process of creating custom aluminum products. This can be done through a variety of methods, including welding, bending, and cutting. Aluminium fabrication is used in a variety of industries, including aerospace, automotive, and construction.Major types of aluminum processing include: Casting is the original and most widely used method of forming aluminum into products. Technical advances have been made, but the principle remains the same: Molten aluminum is poured into a mold to duplicate a desired pattern.

Our guide will walk you through the entire process of how aluminium is made, from extracting the raw materials to turning it into the finished product.

where does aluminium come from

when was aluminum first made

Aluminum fabrication is an important manufacturing process you can use to make many parts. Whether you want to make aluminum profiles, aluminum enclosures, or aluminum automotive parts – you will adopt efficient and cost-effective techniques to fabricate aluminum.The art of aluminum fabrication involves aluminum bending, cutting, and assembling to create various products. This is an art-science combination that requires both advanced machines and skilled workers.

Aluminum fabrication is the process of transforming raw aluminum into components, parts, or end products through various techniques and methods. This process involves multiple stages, from designing and cutting to forming, machining, and finishing.

In the simplest terms, aluminum fabrication is the process of shaping aluminum into a finished design or product. From intricate aerospace parts to everyday household items — aluminum fabrication can do it all. Its extreme versatility and durability have caused aluminum to become increasingly popular in creative design and engineering applications. Beginning with bauxite extraction, we explore the transformation into alumina via the Bayer process, and subsequent conversion into aluminum through the Hall-Héroult process. We delve into the creation of aluminum alloys and their various applications, and the techniques employed in aluminum shaping.In general, the aluminum-making process involves three steps: mining for bauxite, extracting alumina from the mined bauxite and turning the alumina into aluminum. In this guide, we’ll look at each step of the aluminum production process from .

Primary production involves mining bauxite deposits from the earth, chemically refining it into pure aluminum oxide and performing electrometallurgical processing to ultimately form aluminum. Secondary production makes new aluminum from recycled scrap that for many products, like cans, is completely suitable for the same high quality.Aluminium fabrication is the process of creating custom aluminum products. This can be done through a variety of methods, including welding, bending, and cutting. Aluminium fabrication is used in a variety of industries, including aerospace, automotive, and construction.Major types of aluminum processing include: Casting is the original and most widely used method of forming aluminum into products. Technical advances have been made, but the principle remains the same: Molten aluminum is poured into a mold to duplicate a desired pattern.

Our guide will walk you through the entire process of how aluminium is made, from extracting the raw materials to turning it into the finished product. Aluminum fabrication is an important manufacturing process you can use to make many parts. Whether you want to make aluminum profiles, aluminum enclosures, or aluminum automotive parts – you will adopt efficient and cost-effective techniques to fabricate aluminum.The art of aluminum fabrication involves aluminum bending, cutting, and assembling to create various products. This is an art-science combination that requires both advanced machines and skilled workers.

Aluminum fabrication is the process of transforming raw aluminum into components, parts, or end products through various techniques and methods. This process involves multiple stages, from designing and cutting to forming, machining, and finishing. In the simplest terms, aluminum fabrication is the process of shaping aluminum into a finished design or product. From intricate aerospace parts to everyday household items — aluminum fabrication can do it all. Its extreme versatility and durability have caused aluminum to become increasingly popular in creative design and engineering applications.

how is aluminum produced

big steel box hours

$45.77

aluminum fabrication process|how is aluminum obtained