ceiling fixture box junction box insulate Even though light fixtures fasten tight to the ceiling, there’s enough of a gap to let air flow through the many holes in and around the electrical boxes they’re fastened to. In this video, Mike Guertin shows how to caulk these penetrations. Sheet metal screws come in various lengths, grades, drive types, thread types and materials (such as stainless steel). Uses of sheet metal screws include sealing panels, attaching hinges to cabinets and mounting decorative fixtures.Sheet metal fabrication transforms flat metal sheets into parts and components that have a specific shape and size. During this process, operators use different power tools to cut, bend, and roll sheet metal into functional forms ready for assembly.

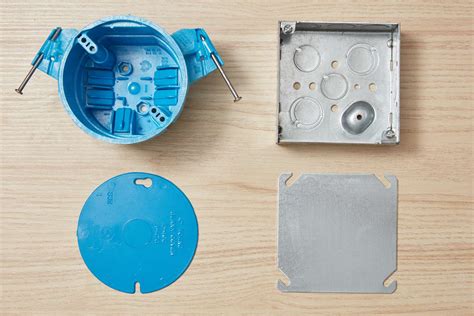

0 · types of ceiling junction boxes

1 · suspended ceiling junction box

2 · junction box wall mounted

3 · installing junction box in ceiling

4 · install ceiling fan junction box

5 · electrical junction box requirements

6 · electrical box for suspended ceiling

7 · ceiling mounted junction box

Launching a metal fabrication business involves both initial and ongoing costs, including rent, utilities, payroll, and equipment maintenance. A detailed budget and a clear.

Even though light fixtures fasten tight to the ceiling, there’s enough of a gap to let air flow through the many holes in and around the electrical boxes they’re fastened to. In this video, Mike Guertin shows how to caulk these penetrations. Here we have an electric box in a ceiling for a light fixture below. All of the knockouts in the sides of the box have little gaps, as well as where the wire itself goes .

if you have ceiling light fixtures like recessed light, adding insulation around them may create a fire hazard. The fixture must be rated to be in contact with insulation and many low cost are not. The junction boxes that contain splices and are not accessible from the ceiling below should be exposed - not covered by insulation. If enough slack is present in the cables .

Even though light fixtures fasten tight to the ceiling, there’s enough of a gap to let air flow through the many holes in and around the electrical boxes they’re fastened to. In this video, Mike Guertin shows how to caulk these penetrations. Here we have an electric box in a ceiling for a light fixture below. All of the knockouts in the sides of the box have little gaps, as well as where the wire itself goes through. We want to seal all of those knockouts up — both the ones that have wires running through them, and even the ones that don’t have wires running through them — so . In our personal opinion we would suggest that before you cover the junction box with insulation, you should considering installing access panels in the ceiling that open directly to these concealed boxes. You can cover those access panels .if you have ceiling light fixtures like recessed light, adding insulation around them may create a fire hazard. The fixture must be rated to be in contact with insulation and many low cost are not.

The junction boxes that contain splices and are not accessible from the ceiling below should be exposed - not covered by insulation. If enough slack is present in the cables between the boxes, you may be able to raise them up a bit and mount them on trusses or other exposed framing members without having to run new wire.

An alternative to filling the junction box with fiberglass insulation is foam insulation around electrical junction boxes. That way, you can prevent energy loss and still use your outlet.

Elevate attic safety with our guide on junction box in attic usage. Learn installation rules, NEMA categorizations, and crucial FAQs for a secure wiring setup. What Is A Junction Box? A junction box is an electrical enclosure that houses one or more wiring connections. We know that the covers for electrical boxes need to be accessible, but what if the box is located in an attic? Is it acceptable to bury the box in insulation? I said I’d research this info and get back to him, but I thought this might make for a good, short blog post topic. Thermal insulation must be installed a minimum distance of 3 inches from any recessed lighting fixture, wiring compartment or ballast. Additionally, the insulation cannot be installed above the fixture in a way that would trap heat and prevent air circulation. One of the suggestions was caulking around overhead light fixture junction boxes from the attic side. Seems like a lot of work for minimal gains. Does anyone think that's a significant source of heat loss? I have 12" of insulation in my attic and 5 overhead fixtures.

Even though light fixtures fasten tight to the ceiling, there’s enough of a gap to let air flow through the many holes in and around the electrical boxes they’re fastened to. In this video, Mike Guertin shows how to caulk these penetrations. Here we have an electric box in a ceiling for a light fixture below. All of the knockouts in the sides of the box have little gaps, as well as where the wire itself goes through. We want to seal all of those knockouts up — both the ones that have wires running through them, and even the ones that don’t have wires running through them — so . In our personal opinion we would suggest that before you cover the junction box with insulation, you should considering installing access panels in the ceiling that open directly to these concealed boxes. You can cover those access panels .if you have ceiling light fixtures like recessed light, adding insulation around them may create a fire hazard. The fixture must be rated to be in contact with insulation and many low cost are not.

The junction boxes that contain splices and are not accessible from the ceiling below should be exposed - not covered by insulation. If enough slack is present in the cables between the boxes, you may be able to raise them up a bit and mount them on trusses or other exposed framing members without having to run new wire. An alternative to filling the junction box with fiberglass insulation is foam insulation around electrical junction boxes. That way, you can prevent energy loss and still use your outlet.Elevate attic safety with our guide on junction box in attic usage. Learn installation rules, NEMA categorizations, and crucial FAQs for a secure wiring setup. What Is A Junction Box? A junction box is an electrical enclosure that houses one or more wiring connections.

We know that the covers for electrical boxes need to be accessible, but what if the box is located in an attic? Is it acceptable to bury the box in insulation? I said I’d research this info and get back to him, but I thought this might make for a good, short blog post topic. Thermal insulation must be installed a minimum distance of 3 inches from any recessed lighting fixture, wiring compartment or ballast. Additionally, the insulation cannot be installed above the fixture in a way that would trap heat and prevent air circulation.

types of ceiling junction boxes

suspended ceiling junction box

junction box wall mounted

installing junction box in ceiling

install ceiling fan junction box

Fabricators typically work with metal and shape products from raw materials. They shape, form, and join pieces through use of special tools like shears, lathes, and presses. There are many types of fabricators. Some of the main types include foundry workers, welders, pipefitters, and boilermakers.What does a metal fabricator do? Metal fabricators are the professionals responsible for the metal fabrication of various materials, machinery and other metal-made products. They often work for manufacturing and construction businesses and have daily duties that consist of using metals to . See more

ceiling fixture box junction box insulate|ceiling mounted junction box