how many axis in cnc lathe machine While the number of axes can vary depending on the specific machine and its purpose, typically, a CNC lathe will have two to four axes. The most common configuration for a CNC lathe is two-axis, known as X-axis and . The iPhone XR display has rounded corners that follow a beautiful curved design, and these corners are within a standard rectangle. When measured as a standard rectangular shape, the screen is 6.06 inches diagonally (actual viewable area .

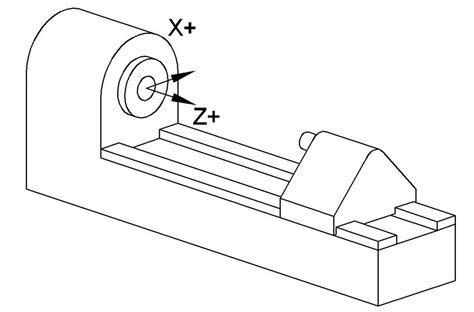

0 · machining lathe axis diagram

1 · lathe axis diagram

2 · cnc xyz axis chart

3 · cnc machine axis locations diagram

4 · cnc machine axis direction

5 · cnc lathe axis directions

6 · cnc axis chart

7 · axis identification in cnc machine

Looking at the tag bracket front side, there is an arrow cast into the middle bar; Arrow needs to point up when properly installed. To install, with bracket arrow up, insert the 2 upper brackets (hooks no holes) into the matching slots on the steel bumper, centered 6” .

How Many Axes in CNC Lathe Machines? CNC lathe machines vary in the number of axes they use, which significantly affects their capabilities and the complexity of parts they can produce. . While the number of axes can vary depending on the specific machine and its purpose, typically, a CNC lathe will have two to four axes. The most common configuration for a CNC lathe is two-axis, known as X-axis and . In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various .

CNC lathe machines typically have three axes: X, Y, and Z. The X axis is the primary axis and is used to control the position of the cutting tool. The Y axis is used to control the feed rate of the cutting tool, and the Z axis is used . CNC mills are usually 3 axis machines and lathes are 2 axis. Both types of machines can have more axes but let’s keep things simple. Less axes are usually easier to understand so let’s start with 2 axis coordinates. Whether you are shopping for a manual engine lathe or power lathe, a mini-lathe that fits on your workbench, or a multi-axis CNC lathe for large-scale projects, you’re making a substantial investment, and there are things . The number and type of axes dictate the complexity of parts the machine can produce. Here’s a quick look into the most common CNC machine axis layouts—3-axis, 4-axis, and 5-axis—and see how they stack up. The 3 .

A CNC lathe machine typically has two primary axes: the X-axis, which runs horizontally, and the Z-axis, which runs vertically. However, some machines may also have a third axis, the Y-axis, which runs perpendicular to .If we speak in general terms, a CNC machine has a minimum of 2 axes which operates along the X, Z plane. X axis denotes the vertical plane and Z axis represents depth. But 3-axis CNC lathes are more versatile. Find out below .A 5-axis CNC lathe adds an additional turret, enabling two tools to work simultaneously. Applications: Increased Speed: Drastically reduces machining time by using two tools at once. Complex Geometries: Can handle very intricate shapes and designs. 6 or More Axis CNC Lathe. Machines with 6 or more axes offer even greater flexibility and . Even basic CNC lathes will be fully capable of 3-axis movement; many will be four-axis, and some – the most powerful machines – will be able to rotate on 5 or even 6 axes. These machines take the traditional 3 axes – X, Y, and Z – and add rotational axes. The A-axis rotates around the X, the B-axis around the Y, and the C-axis around the Z.

Traditionally, lathes have only the X and Z axes for linear movement. However, with the addition of the C-axis, lathes can perform multi-axis machining operations. In this article, we will explore the capabilities of the C . The various axes determine how the workpieces can be positioned, rotated, and handled during the machining process. 2-Axis CNC Lathe. This CNC lathe is the most basic type, containing two linear axes, X and Z axes. It can be used for OD and ID machining of workpieces, face machining, or drilling and tapping in the center of the part. .

I'm trying to figure out exactly how much can be run from a 200amp(160 amp at 100%duty) single phase service. In reality I'd see myself more likely to have a smaller cnc lathe along the lines of a 5 or 7.5hp gangtool lathe and maybe a robodrill type mill. Would be ideal to run both at the same time, and perhaps even a 3hp manual machine. 2-Axis CNC Lathe. A 2-Axis CNC Lathe is the fundamental model in CNC machining. It operates on two linear axes, X and Z. The X-axis controls the diameter, moving the tool inwards and outwards, while the Z-axis controls the length, moving the tool back and forth along the workpiece. This setup is ideal for simple and symmetrical parts. I can't find a placard on my CNC lathe. 240V, 3 phase, 7.5 KW (10 HP) spindle motor, 0.75 KW hydraulic pump Test Conditions: Run from a homebrew 15 HP rotary phase converter 85% spindle load Hydraulic pump on Four 1.8 KW Axis servos on, but not moving Results, single phase feed measured at the input to the RPC disconnect: 239V, panel gauge .

A CNC lathe is a machine that has a spindle that holds a workpiece. Lathes drive their set of cutting tools over two different axes. . This will command the machine to automatically jog each axis to its saved “set” 0.00 position according to the recorded coordinates at the first line of the program. Slide 1. 18. Create a “Home . The various axes determine how the workpieces can be positioned, rotated, and handled during the machining process. 2-Axis CNC Lathe. This CNC lathe is the most basic type, containing two linear axes, X and Z axes. It can be used for OD and ID machining of workpieces, face machining, or drilling and tapping in the center of the part. .For over 65 years, Star CNC machines set the standard for Swiss-type automatic lathes. Our customers trust us for uncompromising machinery performance. StarCNC. Open Menu. . The Star SX-38 Type A/B, a 12-axis compact Swiss-style machine with slant-bed construction, maximizes productivity for difficult-to-machine materials up to 42mm diameter. .

The 4 th axis denotes the inclusion of an A axis (rotation around the X axis), and the 5 th axis denotes the B axis (rotation around the Y axis). The number of axes on a CNC machine determines the type of work it can do, the level of detail it can cut, and the workpiece locations it can manipulate.

In conclusion, CNC lathe machines offer undeniable advantages. They contribute to increased productivity and efficiency, improved accuracy and precision, enhanced safety features, and flexibility and versatility in manufacturing processes. As industries continue to evolve and demand higher-quality products, CNC lathe machines will play a crucial role in meeting these . Recently, the CNC lathe machine, a precision machine tool machinists employ for various woodturning and metalworking projects, has become the go-to lathe for machining high-volume components that require accuracy and repeatability and the most complex projects. . Most two-axis lathes come with a spindle, chuck, lathe bed, and carriage, but .

You would mostly just use the machine in 2D with the mill moving in and out of the panel to cut in a binary fashion. 2.5D software is likely cheaper and simpler to use. I think a 2.5D CNC hardware would be one with very limited Z axis travel and limited rigidity in the Z dimension. I don't think it means how many axis can be used at the same time.

Study with Quizlet and memorize flashcards containing terms like The basic milling machine is capable of moving in how many directions?, When the machine moves, we describe the machine as moving in a specific axis. What direction .CNC machines have revolutionized the manufacturing industry with their precision and efficiency. These computer-controlled machines can produce complex parts and components with utmost accuracy. The role of the axis in CNC machines .What is a CNC Lathe and How Does it Work? Now that we know what a CNC lathe is, the next step is to discover some of its main parts. In this case we are talking about a basic CNC lathe. Main Spindle: The main spindle consists of a .

are metal houses safe

What is a 6 Axis CNC Router? Every CNC router, mill, and lathe use axes which are essential to the manufacturing process. This is because the axes determine how both the tools and workpieces move during production. 3 axis CNC machines are the simplest and have X, Y, and Z-axis which move left to right, front to back, and up and down. 4 axis machines add an . It operates exactly like any other 2-axis lathe. The second machine-tool-in-one is a four-axis machining center." Y-Axis And Job Shops. According to Mr. Venjara, 62 percent of turned workpieces have subsequent machining performed on them. They're all potentially turn/mill users. Of that 62 percent, 25 percent are candidates for Y-axis machining.Rownd CNC lathes and machines equipped with CNC lathe live tooling expand these capabilities even further. How Many Axes in a CNC Lathe Machine? Standard CNC lathes typically come with 2 axes, but advanced models, such as 5-axis CNC lathes or CNC mill lathe combos, are equipped with additional axes that allow for more complex and precise cuts .

Like three-axis machines, the four-axis design has specific uses, but the four-axis style requires more programming at the beginning to get the system set up to create the cuts. Four-axis CNC machines may cut along all four axes at the same time or along the x, y and z axes simultaneously and around the vertical axis separately. These two . An entry-level 3-axis vertical machining center for between ,000 and 0,000; fA production 5-axis CNC mill for 0,000 and up. For more information on the purchasing process, . As a production machine tool, many CNC lathe machines can produce thousands of machined parts in one shift. Other smaller machines are designated for machining . Five-Axis CNC Lathe. A five-axis CNC lathe adds two more axes, typically a tilting rotary axis known as the A-axis and a second tilting rotary axis known as the C-axis. With the additional axes, the five-axis CNC lathe can machine complex surfaces and contours that would be difficult or impossible to achieve with a lower axis machine. The more axes a CNC lathe has, the more complex the shapes it can create. Types of CNC lathe axes. There are several types of CNC lathe axes, including: 1. X-axis: This axis controls the horizontal movement of the cutting tool along the length of the workpiece. It is the primary axis of a CNC lathe and is used for most cutting operations. 2.

Here’s a quick look into the most common CNC machine axis layouts—3-axis, 4-axis, and 5-axis—and see how they stack up. 3-axis CNC machines ; The 3-axis CNC machine lays the foundation for most CNC machining. As the name suggests, it can operate along the three primary X, Y, and Z linear axes. This flexibility allows the tool to shift . I see listings that say "very low time" with 4,000 hours. I see some awfully new machines that say "new spindle". For an ordinary garden variety well maintained 8000 rpm spindle, what would one expect to get before a rebuild? . 5 axis selection tcncj; May 20, 2024; CNC Machining; 2. Replies 24 Views 2K. May 24, 2024. kwirk. K. R. 2006 VF4 .When talking about types of industrial machinery machining, we always refer to the most well-known ones: horizontal or vertical milling machines, 5-axis milling machineries or CNC lathes. Although the CNC lathe is the most popular, there are more types as we will see later. How many types of lathe machines are there?

machining lathe axis diagram

lathe axis diagram

A single gang box, or 1 gang box, is wide enough to enclose only one outlet or switch. Single gang electrical box dimensions vary by manufacturer and type, but are about 2″ wide by 4″ .

how many axis in cnc lathe machine|cnc xyz axis chart