cnc machine used for which type of production In this article, different types of CNC machines based on different classifications were discussed, providing explanations of their functions, applications, limitations, how they are used in manufacturing, and how to select the most suitable CNC . We are sheet metal workers, service technicians, bus operators, engineers, conductors, sign workers, welders, production employees and more. With members in scores of different occupations, we advocate for fairness in the workplace, excellence at work and opportunity for all working families.

0 · what is a cnc mill

1 · types of cnc milling machine

2 · types of cnc machines pdf

3 · technical descriptions of cnc machine

4 · specification of cnc machine

5 · how cnc machine is controlled

6 · different types of cnc machines

7 · computer numerical control cnc machines

$10.68

What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, . CNC Fabrication Machines: These include machines used for bending, punching, or shearing metal sheets, often used in structural metal fabrication. There are seven main types of CNC machines: milling machines, lathes, routers, plasma cutters, laser cutting machines, drilling machines, and grinding machines. CNC technology combines computer control with .CNC technologies are widely used in modern manufacturing and mainly include the following six types of machines: 1. Vertical Milling Machine. (Image from the Internet) The spindle of a .

In this article, different types of CNC machines based on different classifications were discussed, providing explanations of their functions, applications, limitations, how they are used in manufacturing, and how to select the most suitable CNC .Our guide covers everything you need to know about CNC machines, including uses, types, costs, and key buying considerations. Discover the ideal CNC machine for your needs. . Aaron Lichtig. 7 min read. Published October 4, 2022. Updated September 26, 2024. Learn more about the different types of CNC machines and how they are used in manufacturing. What is a CNC machine? A CNC . A CNC machine (Computer Numerical Control machine) is a computer-operated machine used to manufacture different parts and products. It works by executing pre-programmed commands from computer software, .

Here are 12 of the most common types of CNC machines. Each performs somewhat different machining operations with few human errors, high-speed processes, and high-quality results. 1. CNC Milling Machine. CNC . The 15 types of CNC machines listed above are machines that are widely used in manufacturing across several industries. Each CNC machine type has its own unique benefits and is typically application specific. Larger . 3 axis CNC machines are the most common type of CNC machines. They have 3 axes of movement – the X, Y, and Z-axis (depth axis) and can machine the basic parts in 2.5 dimensions. They can work on all six surfaces of a typically square or rectangular block of material, but the block requires repositioning.

Here’s a closer look at the primary types of CNC machines and their applications. CNC Machining Centers (Milling) CNC milling machines are among the most versatile and widely used in the industry. They operate by rotating a cutting tool against a stationary workpiece, allowing for intricate shapes and designs to be crafted with high precision . In this article, we'll explore the different types of CNC machines and how they're used to achieve high precision, increased productivity, enhanced design flexibility, reduced waste, and improved safety in modern manufacturing. . This makes CNC machining ideal for low-volume production runs and personalized products, giving businesses the . There are many different types of CNC machines, each with their own unique capabilities. In this guide, we'll take a look at the different types of CNC machines and what they're used for. . Typically, the CNC drilling machine is used for mass production. However, multi-function machining centers are frequently twisted and mixed in drilling .

How CNC machining works. Though many types of CNC machine exist, all of them work by transforming a piece of material into a finished product by subtractive manufacturing techniques. In layman’s terms, this means that CNC machines work by removing material from the initial piece, rather than adding new material to it. The Different Types of CNC Machines. In advanced composite manufacturing, different types of CNC machines are used to meet diverse production needs. These include milling machines, turning machines, router machines, plasma cutters, laser cutters, electrical discharge machines and 3D printing machines.Router CNC machines share similarities with CNC milling machines but are typically used for larger workpieces and softer materials such as wood, plastics, and soft metals. CNC routers excel in applications requiring large-scale engraving, cutting, and shaping, making them a favorite in industries like signage, cabinetry, and prototyping. In manufacturing and engineering, CNC machines have changed how we make detailed and accurate parts. These machines use computers to control cutting tools, making production precise and efficient. This article will look at 12 types of CNC machines that are crucial in different industries. But before we begin, What is a CNC Machine?

what is a cnc mill

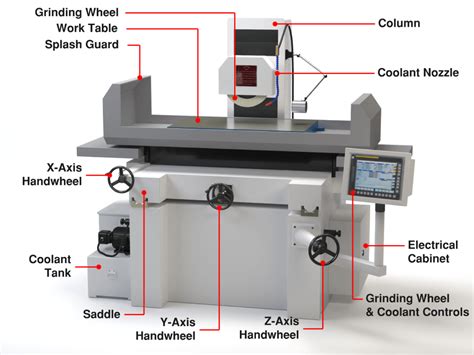

Delve into the types and capabilities of CNC machines, empowering engineers with a comprehensive understanding of their diverse applications. . and centerless grinding for continuous production. These machines use abrasive wheels to precisely shape and finish materials, ensuring high surface quality and dimensional accuracy. Wheel Types .Our guide covers everything you need to know about CNC machines, including uses, types, costs, and key buying considerations. Discover the ideal CNC machine for your needs. . By reducing errors and increasing production speed, CNC machines offer long-term savings for both hobbyists and businesses. Buy a CNC Machine at Onefinity CNC. Batch production is a method whereby the components of an item are produced in separate stages on separate machines to create different batches of products. Using CNC machines for batch production can streamline the workflow because of the reliability, accuracy, and speed of CNC-based manufacturing. The Benefits CNC machining offers immediate cost .There are various types of CNC machine tools available, each designed for specific manufacturing tasks. These machines differ in terms of operations, processes, and applications, allowing manufacturers to choose the best tool based on their production needs. Below, we explore the most common CNC machine tools used in CNC machining factories .

CNC engraving machine is widely used in the fields of woodworking, furniture manufacturing, advertising signs and model making. 9. CNC EDM Machine. CNC EDM machines are capable of machining very hard metals or complex shapes by eroding the material through electrical discharge.

Learn about the different types of CNC machines, the pros and cons of each, and a comprehensive guide to the CNC machining process. Close; . CNC machine tools for machining can accurately calculate the working .

The initial stage in CNC machine design is to determine the type of machine required based on the materials and components that will be processed. This step involves evaluating the production requirements, the types of materials to be worked on, and the desired output. Based on these considerations, a suitable CNC machine type can be selected. 2. The most complex device in the manufacturing industry is a 12-axis CNC machine. It has two cutting heads that can move along all six axes (X, Y, Z, A, B, C). 12-axis CNC machine improves precision and production rates. Types of CNC Machines Based on the Control System. The following are types of CNC machines based on the control system.

Small batch production is a type of production that refers to the high-quantity manufacturing of goods and products, . There are multiple types of CNC machines that are used for small batch manufacturing and production. Here at HDC Manufacturing, we take advantage of our conspired knowledge, skill, and experience in the field of industrial . The following three types of CNC machine tools and fixtures are recommended for priority use in small batch production: ① Combined fixture Modular fixtures, also known as “building block fixtures,” are comprised of a series of standardized machine tool fixture elements with different functions and sizes.

Repetition: As expected, CNC machines also do well when it comes to producing closely related or identical machine parts. For mass production, you can rest assured that any of the different types of CNC machines will easily come in handy. At the end of the day, efficiency and precision are the goals of CNC machines.

Study with Quizlet and memorize flashcards containing terms like Why were many companies slow to develop numerical control technology in the 1950s?, The development of the minicomputer converted numerical control technology to ______. A. punched paper tape B. automated numerical control C. computer numerical control D. programmed codes, A major .

The marine industry relies on CNC machines for the production of highly precise parts that are essential for the smooth operation of ships and vessels. CNC technology enables the manufacturing of propellers, valves, pump components, and other critical marine parts, ensuring reliability and efficiency in maritime operations. Different types of CNC machines are employed to handle various tasks, each offering unique capabilities suited to specific applications. Some common types of CNC machines used are: 5-Axis CNC Mills. 5-axis CNC milling machines are widely used in aerospace manufacturing due to their ability to move a tool or part along five different axes . Types of CNC Machine – In the Computer Numerical Control (CNC) machining process, production equipment and tools are moved according to pre-programmed computer software. The procedure may be used to operate a variety of complicated machinery, including mills, CNC routers, lathes, and grinders.

Types of CNC machines. Machining with a CNC machine is usually connected with a numerically controlled mill. . Due to high production capacity and control modern CNC machines can be found in almost every industry. CNC mills. Just like traditional mills (manual, automatic) are used for chip processing and their principle is almost the same .

sheet metal fabricators san antonio tx

types of cnc milling machine

Lunch Box: Made of superior food-grade stainless steel, material thick texture hard, no distortion, excellent durability. Perfect for putting salads, sandwiches, snacks. Lunch Bag: Felt + foil design provides insulation. With the lunch bag, this set keeps hot food warm for 1-2 hours.

cnc machine used for which type of production|how cnc machine is controlled