advantages and disadvantages of cnc milling machine CNC Milling or manual milling is a precision machining process used to process prismatic parts. A milling cutter with a rotating cylindrical tool head and multiple flutes is usually called an end mill. It can move along different axes and is . Experience unparalleled precision with ProtoEdge's sheet metal fabrication services. We specialize in crafting custom-built components, focusing on delivering the highest quality parts for low to mid-volume production runs and prototype machinery components.

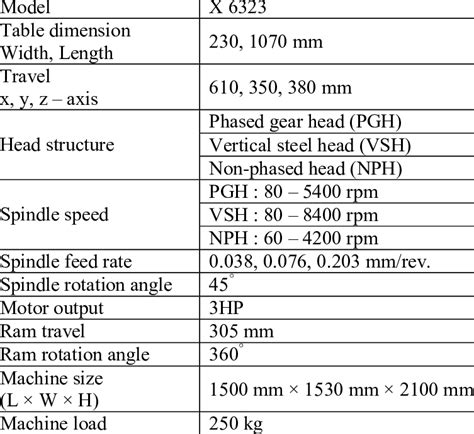

0 · specifications of cnc milling machine

1 · pros of cnc machining

2 · limitations of cnc milling

3 · cnc milling pros and cons

4 · cnc milling advantages and disadvantages

5 · cnc machine pros and cons

6 · cnc machine advantages and disadvantages

7 · advantages and disadvantages milling process

As a professional stamping part factory, we stock more than 30 engineering-grade plastic and metal materials that are suitable for various OEM sheet metal stamping parts applications and industries. Materials range from plastics like ABS, polycarbonate, nylon, and PEEK to aluminum, stainless steel, magnesium, and copper.

Some of the key advantages of CNC milling include: The precision and consistency of it machines contribute significantly to enhancing your efficiency and productivity. With reduced errors and faster task completion of . CNC machining has revolutionised manufacturing with its numerous CNC machine advantages when compared to conventional machining. By replacing manual processes with computer numerical control, it offers . Unlike other manufacturing methods, CNC milling allows machine shops to produce large quantities or a single model. CNC machines don’t limit you to how many parts you can have manufactured at once, allowing you to .CNC Milling or manual milling is a precision machining process used to process prismatic parts. A milling cutter with a rotating cylindrical tool head and multiple flutes is usually called an end mill. It can move along different axes and is .

CNC milling boasts a plethora of advantages, rendering it a compelling choice for diverse manufacturing applications. Let us delve deeper into these benefits, examining the specific mechanisms and quantifiable outcomes .

Here CNClathing.com presents the CNC milling advantages & disadvantages, benefits, applications, materials, types, definition and more. What is CNC Milling? CNC milling is a machining method that uses the multi-point . CNC milling machines are advantageous due to their unmatched precision in producing specific and highly resilient parts. They can provide high levels of accuracy, making . CNC machining significantly improves material utilization by optimizing cutting paths and minimizing waste. The precision of CNC machines allows for tighter tolerances, .In this article, we will explore the advantages and disadvantages of using CNC milling machines, helping you understand the impact they can have on your business. Advantages of CNC .

CNC milling is a machining process that uses computerized controls and cutting tools to selectively remove material from a workpiece and produce a custom-designed part. A CNC milling machine features a table that automatically moves (or rotates) the workpiece on different planes so the cutting tool can work on it. Some of the key advantages of CNC milling include: The precision and consistency of it machines contribute significantly to enhancing your efficiency and productivity. With reduced errors and faster task completion of cnc milling operations, . CNC machining has revolutionised manufacturing with its numerous CNC machine advantages when compared to conventional machining. By replacing manual processes with computer numerical control, it offers precision, consistency, . Unlike other manufacturing methods, CNC milling allows machine shops to produce large quantities or a single model. CNC machines don’t limit you to how many parts you can have manufactured at once, allowing you to use your money and resources more efficiently.

metal fabrication company cardiff limited

CNC Milling or manual milling is a precision machining process used to process prismatic parts. A milling cutter with a rotating cylindrical tool head and multiple flutes is usually called an end mill. It can move along different axes and is used to machine long . CNC milling boasts a plethora of advantages, rendering it a compelling choice for diverse manufacturing applications. Let us delve deeper into these benefits, examining the specific mechanisms and quantifiable outcomes that . Here CNClathing.com presents the CNC milling advantages & disadvantages, benefits, applications, materials, types, definition and more. What is CNC Milling? CNC milling is a machining method that uses the multi-point rotary milling cutter to remove materials from the workpiece making feed motion on the CNC milling machine, to create a broad .

CNC milling machines are advantageous due to their unmatched precision in producing specific and highly resilient parts. They can provide high levels of accuracy, making them ideal for unique designs and critical components. One of the most important advantages of CNC milling machine is its power to operate with unmatched speed and efficiency. CNC machining significantly improves material utilization by optimizing cutting paths and minimizing waste. The precision of CNC machines allows for tighter tolerances, enabling manufacturers to maximize the use of raw materials.In this article, we will explore the advantages and disadvantages of using CNC milling machines, helping you understand the impact they can have on your business. Advantages of CNC Milling Machines. 1. Increased Efficiency: One of the biggest advantages of CNC milling machines is their ability to work at high speeds while maintaining accuracy.

CNC milling is a machining process that uses computerized controls and cutting tools to selectively remove material from a workpiece and produce a custom-designed part. A CNC milling machine features a table that automatically moves (or rotates) the workpiece on different planes so the cutting tool can work on it.

Some of the key advantages of CNC milling include: The precision and consistency of it machines contribute significantly to enhancing your efficiency and productivity. With reduced errors and faster task completion of cnc milling operations, . CNC machining has revolutionised manufacturing with its numerous CNC machine advantages when compared to conventional machining. By replacing manual processes with computer numerical control, it offers precision, consistency, . Unlike other manufacturing methods, CNC milling allows machine shops to produce large quantities or a single model. CNC machines don’t limit you to how many parts you can have manufactured at once, allowing you to use your money and resources more efficiently.CNC Milling or manual milling is a precision machining process used to process prismatic parts. A milling cutter with a rotating cylindrical tool head and multiple flutes is usually called an end mill. It can move along different axes and is used to machine long .

CNC milling boasts a plethora of advantages, rendering it a compelling choice for diverse manufacturing applications. Let us delve deeper into these benefits, examining the specific mechanisms and quantifiable outcomes that . Here CNClathing.com presents the CNC milling advantages & disadvantages, benefits, applications, materials, types, definition and more. What is CNC Milling? CNC milling is a machining method that uses the multi-point rotary milling cutter to remove materials from the workpiece making feed motion on the CNC milling machine, to create a broad . CNC milling machines are advantageous due to their unmatched precision in producing specific and highly resilient parts. They can provide high levels of accuracy, making them ideal for unique designs and critical components. One of the most important advantages of CNC milling machine is its power to operate with unmatched speed and efficiency.

specifications of cnc milling machine

pros of cnc machining

CNC machining significantly improves material utilization by optimizing cutting paths and minimizing waste. The precision of CNC machines allows for tighter tolerances, enabling manufacturers to maximize the use of raw materials.

metal fabrication cutting tools making sparks four wheeler

China Junction Box Cover wholesale - Select 2024 high quality Junction Box Cover products in best price from certified Chinese Electric Box manufacturers, Power Distribution suppliers, wholesalers and factory on Made-in-China.com

advantages and disadvantages of cnc milling machine|pros of cnc machining