is a 3d printer a cnc machine Is 3D printing or CNC machining better for your custom part applications? Learn the practical differences between CNC machining and 3D printing and how to select the right technology for manufacturing prototypes, end-use parts and . Steel Tool Roller Cabinet: 26-1/2" Wide, 31" High, 5 Drawer MSC# 45706512 Mfr# WS-MH-TSTOR-007

0 · snapmaker official website

1 · convert 3d printer to cnc

2 · best 3d printer for cnc

3 · best 3d laser printer engraver

4 · 3d printing and cnc machining

5 · 3d printer with laser etching

6 · 3d printer cnc mill combo

7 · 3d printed cnc mill

$451.99

metal boxing levius

3D printing delivers parts quickly, whereas CNC machining requires individual setup and (generally) manual programming plus supervision. 3D printing is generally a lower-cost method than other ways of making . CNC machines come in all sorts of guises, even 3D printers. Read on to learn the differences between CNC vs. 3D printers!

Is 3D printing or CNC machining better for your custom part applications? Learn the practical differences between CNC machining and 3D printing and how to select the right technology for manufacturing prototypes, end-use parts and .The key difference is that 3D printing is an additive manufacturing process, while CNC machining is subtractive. But what does that even mean? Read on to know what these two processes are, as well as their differences. 3D Printing vs. .Material removal is typically faster than deposition, making machining faster than printing. However, CNC machining requires more setup times to prepare the tooling and programming. .CNC machines are known for their accuracy and precision, making them ideal for high-precision applications. 3D printing, on the other hand, is ideal for prototyping and for creating complex shapes and geometries quickly and inexpensively.

metal bracket attach to shelves

3D printing and CNC machining are both capable of producing parts in metals and polymers, so the choice will revolve around which process is more readily available for forming the material that you need. 3D Printing vs. CNC Machining: Understanding the Differences Between These Technologies. By Protolabs. Manufacturing methods abound these days. Product designers and engineers have a stunning range of . The Snapmaker 2.0 also works as a laser cutter as well as a 3D printer. The CNC machine can carve designs on walnut, PCB woods, as well as carbon fiber sheets, acrylic and hardwood. A key upgrade on the 2.0 is the increased speed, meaning that larger projects can be created in record time.Any geometry you can design, can be 3D printed. CNCs, you need to think about DFM (design for manufacturing), for instance, I can make a perfectly square hole that bends 90 degrees at the bottom on a 3D printer, but not on a CNC. 3D .

Open source large format CNC-machine & 3d-Printer For a schoolproject we decided to build this CNC-machine. For those, wanting to view the files (with a PDF-Version of . - An optional glass bed for using the machine as a 3D-printer The nuts we used to connect the trapezoidal screw with the C-beam gantry plate also went up significantly in .A subreddit for enthusiasts of Hobbyist CNC machines like the Shapeoko, X-Carve, 6040, etc . If you are into 3D printing and like to tinker/build you will love it. If you want to plug in and get going, this may not be what you want. Best of luck & Enjoy! Reply reply

CNC to 3D Printer Conversion : This instructable is for the people who have their own desktop CNC machine and wish to use it as a 3D printer. . If we compare a desktop CNC machine to a 3D Printer it can be seen that the only real differences are in the tool head and the heated build platform. CNC machines uses spindles but 3D printers use . CNC machines often involve the use of multiple tools, such as drills and saws, to make the needed cuts. . CNC and 3D printers work with mostly different materials, so the materials you need will sometimes determine which technology you must use. CNC can work with a wider range of materials, including high-density metals, wood, wax and plasticIf you have experience with 3d modeling and have done CNC programming with something like masterCAM or visual mill, you will find printing to be quite easy. For machines that take nonproprietary code, you can use something like slic3r or kisslicer to create code. CNC machines come in all sorts of guises, even 3D printers. Read on to learn the differences between CNC vs. 3D printers!

The CNC Machine and the 3d Printer are compatible with multiple materials such as plastic and metals. They are both limited by the tool size. They both have service temperature limits. Differences between CNC Machine and 3d Printer. 3D printing is a form of additive manufacturing, whereas CNC machining is subtractive. That means the CNC .A subreddit for enthusiasts of Hobbyist CNC machines like the Shapeoko, X-Carve, 6040, etc . But the workflow for CNC is not the same as 3D printing. From STL you have to create paths and then GCODE. While in 3D printing it can be done with a slicer, for CNC it's a bit more complex and you'll have to find the tool(s) that work for you. .

In this comprehensive guide, we will walk you through the process of converting your Ender 3 3D printer into a CNC machine. Table of Contents: 1. Understanding the Basics of CNC Machines . 2. Assessing the Feasibility of Converting the Ender 3 . 3. Gathering the Necessary Materials and Tools . 4. Preparing the Ender 3 for the Conversion .

The major difference between a 3D printer and a CNC machine is that 3D printing is a kind of additive manufacturing process while CNC is a subtractive manufacturing process. This implies that CNC machines start with a block of material called a blank and machines away parts of the material to produce the finished product whilst the 3D printer . Technically, almost any 3D printing technology could be combined with a CNC machine and there are a few upgrade kits to convert your existing machining units. However, the technology is still developing and the current options are limited to a few combinations. These include: DED/CNC: Directed energy deposition (DED) is a metal AM technology where the .To transform the 3D model into gcode (format that both CNCs machinery and 3D printers use) you need some program or plugin to "slice" the model. Fusion has tools for CNC machines (Autodesk HSM) directly on the software, but if you want to 3D print you need to extract the 3D model (as an .stl file ) and import on a Slicer.I assume you mean a CNC router (like an Omio), but any kind of machine tool (lathe, mill, bandsaw) can be a CNC machine.. CNC routers are very good at making flat sheet parts. You can print those things, but they're liable to warp, and nowhere near as strong as a solid sheet of plastic (like delrin or lexan), let alone aluminum.

A subreddit for enthusiasts of Hobbyist CNC machines like the Shapeoko, X-Carve, 6040, etc . Most 3D printer oriented boards will run just fine for a nema 17 based CNC, the typical "polulu style" stepper modules or the builtin chips they mostly come with are usually spec'd for 2 amps max (or 1 amp without forced ventilation and proper ./r/3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices. . A subreddit for enthusiasts of Hobbyist CNC machines like the Shapeoko, X .Compared to CNC machines, 3D printers are just not up to par when it comes to precision. However, you can tweak 3D printers to be very accurate. Speed. CNC machines can produce pieces and parts in an hour or less. If you work with a 3D printer, the same piece or part will take several hours to finish. It should be noted that these machines work .

There are however several machines that have sought to combine these two forms of manufacturing in one. Most notably of these, the ZMorph 2.0 SX, is marketed as a CNC mill which also functions as a 3D printer.This includes a CNC mill with 3 axes as well as a print head due to its interchangeable heads.This could be made on both a cnc and a 3D printer, using a STL file. because of the STL format , both machines would take hours to make the part. If you use a more CNC appropriate format the same part could be done on the CNC in less than a minute. The 3D printer would still take hours and hours and hours.

CNC machines can produce parts with smoother surfaces than 3D-printed parts, and you probably want to go with CNC machining if you want your components to fit together with precision. 3D printing yields excellent parts for finish and fit, though the quality of both also depend on which type of 3D printer you’re using.Siemens just successfully tested metal 3D printed turbine blades in an actual operating turbine. However where 3D printing is going to have a really hard time matching CNC technology is speed, quality, and consistency. The current generation 4/5 axis CNC machines can produce incredibly detailed parts, very quickly. This is because CNC machines carve out objects from solid blocks, whereas 3D printers build them layer by layer. If time is a critical factor for your project, a CNC machine may be the better choice. 5. Material Selection. Another important aspect to consider is the range of materials that can be used with 3D printers and CNC machines. 3D .

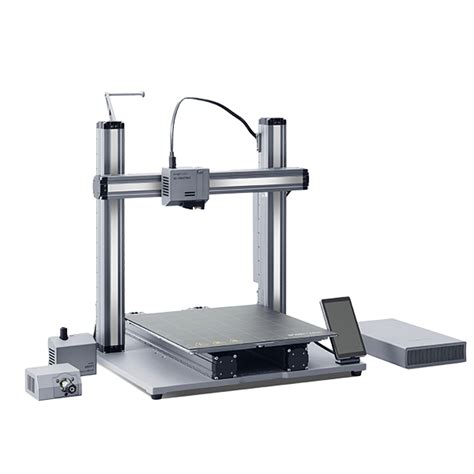

Carbide 3D is a manufacturer of CNC machines that are designed for precision cutting and milling of various materials, including the ever-popular Shapeoko CNC machine and the fully-enclosed Nomad CNC machine. Here are some key features of Carbide 3D CNC machines: Robust construction; User-friendly interface Snapmaker 2.0 A350T is a beautifully engineered all-in-one 3D printer, laser and CNC machine that takes a bit of time, and a good bit of money, to use.

snapmaker official website

Unlike additive manufacturing methods like 3D printing, CNC machining removes material from a solid block—referred to as the workpiece or blank—using a variety of cutting tools to achieve the required geometry. . CNC machines come in various forms to accommodate the diverse needs of the manufacturing industry. Boxzy CNC is a machine that is a CNC mill, a 3D printer and also a laser engraver. It is available in small sizes to easily place them anywhere you want. Purchasing a CNC machine could be a real pain if you are purchasing for the first time. To avoid this problem, you must buy from somewhere you can trust.

convert 3d printer to cnc

best 3d printer for cnc

This blog post will provide step-by-step instructions on how to attach flashing to wood so that anyone can easily learn how to attach flashing correctly—whether it’s for fresh eaves installation or preventing water damage in existing rooflines.

is a 3d printer a cnc machine|3d printed cnc mill