punching holes in sheet metal Looking to create perfect holes during the sheet metal punching and drilling? This post discusses important guidelines for punching in sheet metal. Read here. What is an Electrical Box? An electrical box, often referred to as a junction box, is a container that houses electrical connections and wiring. These boxes protect electrical connections from .

0 · sheet metal punching techniques

1 · sheet metal hole punching machine

2 · sheet metal hole punch tool

3 · sheet metal hand punch tool

4 · punching square holes in metal

5 · punching operation in sheet metal

6 · punching holes in stainless steel

7 · hole punch for thick material

Western Metal Service has a 8kw high speed fiber laser with a 2 meter x 4 .

sheet metal punching techniques

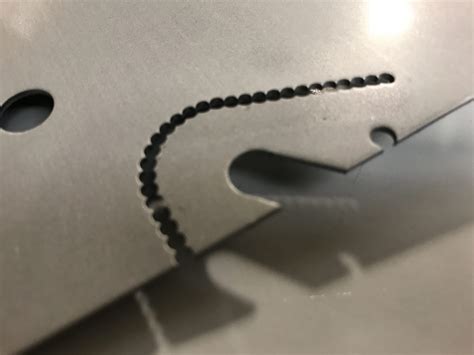

Sheet metal hole punching is a common method to create a hole in a metal sheet. In real practice, the process of hole punching differs . When punching a round hole, the hole naturally collapses slightly after the punch tip penetrates the sheet. A straight punch can rub against the . Looking to create perfect holes during the sheet metal punching and drilling? This post discusses important guidelines for punching in sheet metal. Read here.

Punching and blanking operations are quite different from piercing. Piercing does not remove any material from the sheet of metal. Instead, it only displaces metal, creating an opening that causes slight deformation around .

This process involves creating holes in sheet metal using a punch press or a CNC punching machine, and it is essential for precision fabrication. In this ultimate guide, we will explore the basics of sheet metal punching, its .

A quick way to make holes that are great for use with sheet metal screws (or wood screws for that matter) and won't get stripped as easily as plain punched o.Combine the cutting base and a corner punch to make rounded corners in sheet metal. Benders, Crimpers, & Flarers. Sheet Metal Hole Flaring Dies. Create flares around already-cut holes in sheet metal up to 3/16" thick to make the edges stronger and more rigid. Also known as . Sheet Metal Punching Mechanism. This process is also known as Sheet Metal Hole Punching because it makes different shapes of holes on the sheet. A punch tool exerts force in sheet metal so the intended portion is .

Sheet metal punching results to holes on the surface of the material being worked on while sheet metal shearing is a clean cut that does not produce holes. Calculating Power Of Sheet Metal Punching Machine. The universal power of sheet metal punching calculated using: U = circumference or perimeter of the punch shape (in mm) s = Sheet thickness .

Sheet Metal Hole Punch,2mm Heavy Duty Hand Held Sheet Metal Hole Puncher Tool for Metal Jewelry,Tags,Earring Card, Crafting,Leather Watch Band. 4.7 out of 5 stars. 6. .99 $ 7. 99. FREE delivery Thu, Aug 22 on of items shipped by Amazon. Add to cart-Remove.Campo Sheet Metal Works Inc. provides metal drilling and punching services in Houston, TX and the Gulf Coast Area. Contact us today to learn more. . A 50 ton punch allows punched holes in material up to 1″ thick. Holes can be punched in variety of shapes, rounds, obrounds, squares, and slotted holes are all commonly punched shapes. .

Neiko 02612A Hand Held Power Punch and Sheet Metal Hole Punch Kit, Cr-V 3/32" x 9/32" 15,622. .97 $ 39. 97. 1:02 . Capri Tools CP21050 21050 Metal Hole Punch Set With Puncher 16 Piece, Black 1,176. .99 $ 44. 99. Next page. Product details. The entire purpose of the punching process is to create holes in sheet metal materials. Using hardened tools with sharp edges, force is applied to shear out the desired area. The force can be applied manually, but is typically performed through mechanical, pneumatic, or hydraulic means.Eurotool EuroPunch 1.25mm Round Hole Punch Pliers for Sheet Metal. 4.4 out of 5 stars. 1,076. 50+ bought in past month. .26 $ 15. 26. List: .49 .49. FREE delivery Fri, Feb 16 on of items shipped by Amazon. Or fastest delivery Thu, Feb 15 . Small Business. Small Business. In this episode, Lisa and Mel show awesome tools to punch holes in your metal. We cover hole punch pliers, screw down punches, drilling with a drill and the .

For example, to calculate the punching force for a rectangular hole measuring 1/2 x 5/8 inches in a sheet of steel with a thickness of 3/16 inches and a shear strength of 60,000 PSI: Calculate the perimeter of the hole: P=2x(0.5+0.625)=2.25 inches Hole punching is commonly used on high production sheet metal fabrication such as automotive components, airplane bodies, and decorative work. Advantages and Limitations of Notching Notching generally has the same pros and cons as hole punching as both processes use presses and rely on shear force to sever the material on which the work is .

sheet metal hole punching machine

Sheet metal punching is a manufacturing process used to create holes or shapes in metal sheets or plates with the help of a punch press. In this technique, a punch—a stiff metal rod with a specific shape at one end—strikes the metal sheet placed over a die.Extruded holes with the punch and die used to create them. No pilot hole was used on the left.. Punching is a forming process that uses a punch press to force a tool, called a punch, through the workpiece to create a hole via shearing.Punching is applicable to a wide variety of materials that come in sheet form, including sheet metal, paper, vulcanized fibre and some forms of plastic .As explained in the below image, Piercing is a type of sheet metal punching operation that is used to create an extruded hole or slot in a sheet metal workpiece. In other words, the piercing operation is a combination of cutting . ARES 10005 - Metal Hole Punch Set - 3/32-Inch to 9/32-Inch Punches and Dies Included - for Aluminum, Brass, and Steel Sheet Metal and More 4.6 out of 5 stars 366 1 offer from 36 $ 45 36

Metal sheet punching machines have revolutionized the metal fabrication industry by automating the process of creating precision holes and shapes in metal sheets. This cutting-edge technology has transformed manufacturing processes, providing numerous benefits in terms of efficiency, precision, and versatility. Enhanced Efficiency Reduced Labor Requirements: .

The Eastwood 14 Ga Hand Punch is our take on a classic sheet metal tool every fabricator needs in his tool box. This punch makes quick work of spot weld and rivet holes and produces a clean burr- free hole. . Rated 5 out of 5 by 54 Effie from 54 Ford Effie Project Works great for punching holes in sheet metal to do spot welding of panels .The recommended minimum distance between two hole centers in sheet metal design should be equal to the sum of hole radius plus two times the sheet thickness. . Creating Emboss feature using sheet metal punching requires extreme pressure. Very close emboss to the part edge can lead to deformation in the sheet metal part.Sheet Metal Hole Punch,2mm Heavy Duty Hand Held Sheet Metal Hole Puncher Tool for Metal Jewelry,Tags,Earring Card, Crafting,Leather Watch Band. 4.4 out of 5 stars. 12. 50+ bought in past month. .99 $ 7. 99. Buy 2, save 2%. FREE delivery Sun, .Sheet Metal Punching uses a dedicated punching tool for any project requiring holes in sheet metal. More often than not, customer metal orders require some degree of processing, whether it’s cutting, or customization such as punching holes.Whether for decorative or functional purposes, sheet metal punching is a common customer request.

Sheet metal punching, or subtractive manufacturing, creates holes, slots, or shapes by applying a mechanical punch through sheet metal. The force, usually made of hardened tool steel and pierces through the metal, removes the piece, leaving a precise shape on the sheet. Yes but have you ever tried pumping a pissy hydraulic cylinder up and down all day to punch holes in sheet metal? An arbor press is much quicker than a hydraulic press, even one fitted with a power-pac, and I'd use mine over a hydraulic press if the arbor press was enough tonnage for the job. Good idea to grind some shear in to the dies.

Why are the punched holes I see in sheet metal not the same diameter on the top and bottom side of the sheet? When a hole is punched in sheet metal work either with CNC punch press tooling, fly presses or power presses the action on the tooling process is the same within the material. The diameter of the hole on the top side of the metal sheet .Sheet Metal Hole Punch,2mm Heavy Duty Hand Held Sheet Metal Hole Puncher Tool for Metal Jewelry,Tags,Earring Card, Crafting,Leather Watch Band. 4.4 out of 5 stars. 12. 50+ bought in past month. .99 $ 7. 99. FREE delivery Thu, Oct 31 on of items shipped by Amazon. Or fastest delivery Mon, Oct 28 .Metal Hole Punch, Sheet Metal Hole Punch, Hole Puncher, Steel Keel Fixed Punching Pliers Handle Stud Crimper Grid Hole Punch for Decoration Ceiling, Multifunctional Ceiling Grid Punch Pliers. 4.3 out of 5 stars. 3. .91 $ 28. 91. FREE delivery Wed, Sep 11 .

A hand punch, such as those by Roper Whitney, can be used to make perfect holes in sheet metal quickly and with relatively little effort. For larger holes or use on thicker gauges of steel, more .

Which distribution code should your organization use in Box 7 of IRS Form 1099-R when reporting this distribution? Enter code G, Direct rollover and direct payment, when plan participants or IRA owners directly roll over non-Roth QRP or IRA assets to an eligible employer-sponsored retirement plan.Metal build gundams are probably the most difficult flat out builds. I would strongly recommend against it if you are looking for a good 1/100 for your first time. Try out a regular plastic kit.

punching holes in sheet metal|hole punch for thick material