cnc flip part Need some suggestions on how to hold this part. First op held in bored soft jaws to turn and bore the first 1/2 of the part then flip part to finish. Since.

What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines : There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.

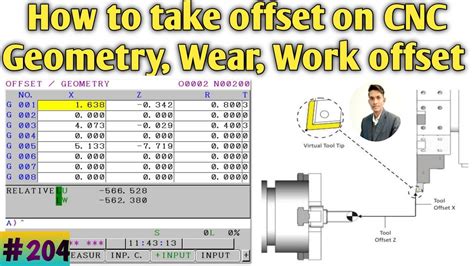

0 · offset in cnc parts

1 · offset for flipping parts

2 · cnc router flip machining

3 · cnc machining offset

4 · 2 sided cnc router parts

Junction boxes come in various sizes, and the screw size depends on the specific box size. For smaller junction boxes, #6 (3.5mm) screws with a length of 0.75 to 1 inch (19 to 25mm) are commonly used.

offset in cnc parts

pvc surface mount junction box

1) Square your stock with your machine so that one edge is parallel to the X-axis. 2) At the start of your program, drill a hole completely through your material at the 0,0 location. In . OP #1 - set your origin on the part not the rough stock. This requires touching off the stock and then insetting to account for the amount of material you want to remove from x,y and .Find how our innovative CNC pneumatic part flip station can streamline your production processes. Learn how it can improve efficiency and productivity. . I was admiring the work this guy is doing http://www.cncgunsmithing.com/projects/ar15lower.html and wondered how you flip work over .

Our Part Flipping Station lets you merge two or more operations into a single cycle. The CNC Part Flipper receives the part from a Spindle Gripper loaded in your mill, flips your partially-milled component, and then transfers the part .

Need some suggestions on how to hold this part. First op held in bored soft jaws to turn and bore the first 1/2 of the part then flip part to finish. Since.Kevin takes you through the process of designing and executing a two sided part. With several examples of how to workhold the B-Side. .more. The process of making two sided CNC parts can. What is a CNC flip part? In this article we have explained the various types of flip part angles and their dimensions that help in accurate cnc machining. 1) Square your stock with your machine so that one edge is parallel to the X-axis. 2) At the start of your program, drill a hole completely through your material at the 0,0 location. In my first trial, I put this in the middle of my stock and machined two parts on either side of the hole.

OP #1 - set your origin on the part not the rough stock. This requires touching off the stock and then insetting to account for the amount of material you want to remove from x,y and z. This will account for varying lengths of rough stock. OP#2 - .

Find how our innovative CNC pneumatic part flip station can streamline your production processes. Learn how it can improve efficiency and productivity. With the CNC Pneumatic Part Flipper, you can machine all operations of a part in a single cycle. I was admiring the work this guy is doing http://www.cncgunsmithing.com/projects/ar15lower.html and wondered how you flip work over in a CNC mill to finish the other side and have it accurately index so that through-holes and channels match up properly.Our Part Flipping Station lets you merge two or more operations into a single cycle. The CNC Part Flipper receives the part from a Spindle Gripper loaded in your mill, flips your partially-milled component, and then transfers the part back to your Spindle Gripper for Second-Op Loading.

offset for flipping parts

Need some suggestions on how to hold this part. First op held in bored soft jaws to turn and bore the first 1/2 of the part then flip part to finish. Since.Our Part Flipping Station for the Haas Robot Package-2 is a heavy-duty pedestal that mounts to the floor, providing a convenient location for the robot arm to place parts and then regrip (flip) for machining the other side. You need to locate on SOMETHING when you flip. It could be two accurate edges, if its something wonky, it could be the whole profile milled into soft jaws. It could be a counterbore, a hole, a sacrificial hole that is going to be removed later, two edges that are going to be removed later (extra features for manufacturing are allowed, in process).Kevin takes you through the process of designing and executing a two sided part. With several examples of how to workhold the B-Side. .more. The process of making two sided CNC parts can.

What is a CNC flip part? In this article we have explained the various types of flip part angles and their dimensions that help in accurate cnc machining.

1) Square your stock with your machine so that one edge is parallel to the X-axis. 2) At the start of your program, drill a hole completely through your material at the 0,0 location. In my first trial, I put this in the middle of my stock and machined two parts on either side of the hole. OP #1 - set your origin on the part not the rough stock. This requires touching off the stock and then insetting to account for the amount of material you want to remove from x,y and z. This will account for varying lengths of rough stock. OP#2 - .

Find how our innovative CNC pneumatic part flip station can streamline your production processes. Learn how it can improve efficiency and productivity. With the CNC Pneumatic Part Flipper, you can machine all operations of a part in a single cycle. I was admiring the work this guy is doing http://www.cncgunsmithing.com/projects/ar15lower.html and wondered how you flip work over in a CNC mill to finish the other side and have it accurately index so that through-holes and channels match up properly.Our Part Flipping Station lets you merge two or more operations into a single cycle. The CNC Part Flipper receives the part from a Spindle Gripper loaded in your mill, flips your partially-milled component, and then transfers the part back to your Spindle Gripper for Second-Op Loading. Need some suggestions on how to hold this part. First op held in bored soft jaws to turn and bore the first 1/2 of the part then flip part to finish. Since.

Our Part Flipping Station for the Haas Robot Package-2 is a heavy-duty pedestal that mounts to the floor, providing a convenient location for the robot arm to place parts and then regrip (flip) for machining the other side.

According to wolf, their polyformance .223 remington, .40S&W and .45 ACP are all boxer primed. Makes sense to me- probably easier to just make boxer primers than redesign the cartridge insides to take berdan primers. I reload Wolf .223 and 45acp all the time. Most, but not all .223 is boxer primed. All Wolf 45acp is boxer primed.

cnc flip part|cnc router flip machining