cnc from old printer parts CNC Machine From Inkjet Printer: Last year I was stripping down an old A3 sized HP 2500C inject printer for parts. Once I got to the base chassis, I realised the . Type 3R Enclosures . All. All Custom ; Material Handling Systems . unity number. Home; Enclosure Solutions. Custom; Material Handling Systems; Building Automation Systems; Distribution; Original Equipment Manufacturer; Explore All Products; Our Culture; Contact; place an order. 800-657-6100

0 · Turn an Old 3D Printer Into a CNC Machine

1 · Turn an Old 3D Printer Into a CNC Machine

2 · Simple CNC From Scrap Printers : 11 Steps

3 · Make a A4 SIZE CNC

4 · How To Make CNC plotter From Old Printer Parts

5 · Home Made CNC Reuses Printer Parts

6 · From Printer to Precision: How to Convert an Old Printer into a

7 · CNC Machine From Inkjet Printer

Check Universal Sheet Metal Incorporated in Woodinville, WA, Northeast North Woodinville Way on Cylex and find ☎ (425) 483-8., contact info, ⌚ opening hours.

Most of the mounts and small parts are made from easily worked PVC sheet stock. Precision rails were scavenged from old Ricoh copiers. .Simple CNC From Scrap Printers: After building my 3D printer out of old printers and MDF and using it for a few years, I want to expand my machine shop with . Bipolar stepper motor controller_Home Madehttps://youtu.be/OsMilSlpCkwprinter shape rodprinter timing beltprinter head timing pulley printer head socket 1/2 .CNC Machine From Inkjet Printer: Last year I was stripping down an old A3 sized HP 2500C inject printer for parts. Once I got to the base chassis, I realised the .

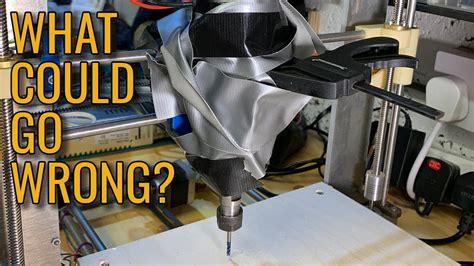

One such example is converting an old printer into a CNC (Computer Numerical Control) machine. In this article, we will explore the step-by-step process of transforming an old printer .3D printers do additive manufacturing using a plastic extruder usually and CNC machines a rotary cutting tool to do subtractive manufacturing by carving away the unwanted material. Surely it’s as simple as swapping out the extruder with .

Thanks for watchingSong: LFZ-Popsicle [ NCS release]Music provided by NoCopyrightSoundsVideo Link: https://youtu.be/K8DUjObr_tU CNC plotterCNCprinter slavag. Most of the mounts and small parts are made from easily worked PVC sheet stock. Precision rails were scavenged from old Ricoh copiers. Epson printers provided the tubing which became motor.Simple CNC From Scrap Printers: After building my 3D printer out of old printers and MDF and using it for a few years, I want to expand my machine shop with a CNC machine. Before to go and buy expensive aluminium extrusions and electronics, I decided to build a small machine out.

Bipolar stepper motor controller_Home Madehttps://youtu.be/OsMilSlpCkwprinter shape rodprinter timing beltprinter head timing pulley printer head socket 1/2 .CNC Machine From Inkjet Printer: Last year I was stripping down an old A3 sized HP 2500C inject printer for parts. Once I got to the base chassis, I realised the thing was sturdy enough to form the base of a CNC machine. 5 days later, I had the first working version of it, complet.

One such example is converting an old printer into a CNC (Computer Numerical Control) machine. In this article, we will explore the step-by-step process of transforming an old printer into a precision CNC machine, opening up a world of possibilities for hobbyists, makers, and tinkerers.3D printers do additive manufacturing using a plastic extruder usually and CNC machines a rotary cutting tool to do subtractive manufacturing by carving away the unwanted material. Surely it’s as simple as swapping out the extruder with the spindle right? Thanks for watchingSong: LFZ-Popsicle [ NCS release]Music provided by NoCopyrightSoundsVideo Link: https://youtu.be/K8DUjObr_tU CNC plotterCNCprinter slavag.

Follow Razihel:http://www.facebook.com/RazihelOfficialhttp://www.soundcloud.com/Razihelhttp://www.youtube.com/razihelOfficialhttp://www.twitter.com/razihelof. When most people salvage parts from an old printer, they usually chuck the rest. In this case [Shane] made use of the entire printer to build his CNC machine. He started with an old HP.Inkjet printer and laser printer all have useful parts that can be salvaged and recycled to be used in other projects. Most people use the parts found in printers to make their own CNC Machines and 3D Printers.

Most of the mounts and small parts are made from easily worked PVC sheet stock. Precision rails were scavenged from old Ricoh copiers. Epson printers provided the tubing which became motor.Simple CNC From Scrap Printers: After building my 3D printer out of old printers and MDF and using it for a few years, I want to expand my machine shop with a CNC machine. Before to go and buy expensive aluminium extrusions and electronics, I decided to build a small machine out. Bipolar stepper motor controller_Home Madehttps://youtu.be/OsMilSlpCkwprinter shape rodprinter timing beltprinter head timing pulley printer head socket 1/2 .CNC Machine From Inkjet Printer: Last year I was stripping down an old A3 sized HP 2500C inject printer for parts. Once I got to the base chassis, I realised the thing was sturdy enough to form the base of a CNC machine. 5 days later, I had the first working version of it, complet.

One such example is converting an old printer into a CNC (Computer Numerical Control) machine. In this article, we will explore the step-by-step process of transforming an old printer into a precision CNC machine, opening up a world of possibilities for hobbyists, makers, and tinkerers.

3D printers do additive manufacturing using a plastic extruder usually and CNC machines a rotary cutting tool to do subtractive manufacturing by carving away the unwanted material. Surely it’s as simple as swapping out the extruder with the spindle right? Thanks for watchingSong: LFZ-Popsicle [ NCS release]Music provided by NoCopyrightSoundsVideo Link: https://youtu.be/K8DUjObr_tU CNC plotterCNCprinter slavag.

Follow Razihel:http://www.facebook.com/RazihelOfficialhttp://www.soundcloud.com/Razihelhttp://www.youtube.com/razihelOfficialhttp://www.twitter.com/razihelof. When most people salvage parts from an old printer, they usually chuck the rest. In this case [Shane] made use of the entire printer to build his CNC machine. He started with an old HP.

Turn an Old 3D Printer Into a CNC Machine

how to install octagon electrical box in ceiling

how to install electrical box supports

Situation: I have a curved, CATIA V4, sheet metal type part (.063” thk). I’m using V5 sheet metal design and others. 1. Create a flat pattern for our router machines. (have CATIA recognize this model as a wall and unfold it) 2. Wrap this .

cnc from old printer parts|Turn an Old 3D Printer Into a CNC Machine