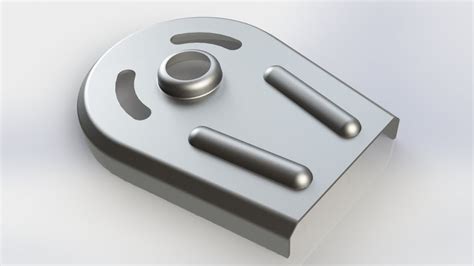

sheet metal forming simulation solidworks Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. The SOLIDWORKS software includes .

Janua, welcome to the forums! The box you have is a fan rated box if the rotating securements will accept a 10-32 screw. The "give" you mention is possibly from the bar the box is attached to. This box was wired previously, before paint was applied. I can see where the grounding wire was secured via a green screw in the center top of the last .

0 · solidworks sheet metal forming tool

1 · solidworks sheet metal forming

2 · solidworks sheet metal add in

3 · solidworks metal forming simulation

4 · solidworks forming tool

5 · solidworks forming simulation

6 · sheet metal forming simulation

7 · forming tool design

Use 314.28 (A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves .

The 3D EXPERIENCE WORKS ® Simulation portfolio includes the ability to simulate the metal-forming process. The products can be leveraged on SOLIDWORKS® .

Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet .Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet .The sheet metal Mirror feature simplifies modeling by using existing features .Click Forming Tool (Sheet Metal toolbar) or Insert > Sheet Metal > Forming Tool. In .

Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. The SOLIDWORKS software includes .

The 3DEXPERIENCE WORKS® Simulation portfolio includes the ability to simulate the metal-forming process. The products can be leveraged on This tutorial provides a step-by-step guide on applying forming tools to design intricate shapes, bends, and cuts commonly used in manufacturing. Whether a beginner or a .

canadian metal fabricators

solidworks sheet metal forming tool

Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. SOLIDWORKS includes some .The sheet metal Mirror feature simplifies modeling by using existing features (Figure 10). However, to ensure that the mirror feature produces the right results, you must understand .Click Forming Tool (Sheet Metal toolbar) or Insert > Sheet Metal > Forming Tool. In the PropertyManager, on the Type tab: Select a face as the Stopping Face. Select one or more . Solidworks Simulation tutorial | Sheet Metal Analysis How to simulate sheet metal part in solidworks In this tutorial you can see few SolidWorks simulation Tools use.

How to carry sheet metal simulation and analysis in solidowrks, learn all this in this video tutorial. How to define sheet metal thickness? How to evaluate stresses at bottom and .Using Forming Tools with Sheet Metal. Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. Sheet Metal Parts. Multibody Sheet Metal Parts. SOLIDWORKS multibody part functionality lets you work with several bodies in one part to create .

Simulation: Sketching: SLDXML Data Exchange: Toolbox: SOLIDWORKS Utilities: . If the forming tool has radii that are pushed into the sheet metal body, then the forming tool will fail when the concave radius is smaller than the material thickness. In this case the radius that gets pushed into the sheet metal body becomes negative and forces .Simulation: SimulationXpress: Sketching: SLDXML Data Exchange: SOLIDWORKS Sustainability . Stamp Tool. You can use the Stamp tool to create sketch-based parametric forming tools to apply to sheet metal parts. .

Using Forming Tools with Sheet Metal. Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. Sheet Metal Parts. Multibody Sheet Metal Parts. SOLIDWORKS multibody part functionality lets you work with several bodies in one part to create .Using Forming Tools with Sheet Metal. Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. Sheet Metal Parts. Multibody Sheet Metal Parts. SOLIDWORKS multibody part functionality lets you work with several bodies in one part to create .

Using Forming Tools with Sheet Metal. Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. Sheet Metal Parts. Multibody Sheet Metal Parts. SOLIDWORKS multibody part functionality lets you work with several bodies in one part to create .You can use the Stamp tool to create sketch-based parametric forming tools to apply to sheet metal parts. With sketch-based forming tools, you can create a sketch with a few parameters to stamp or form the sheet metal. Normal Cut in Tab and Slot. When you use the Tab and Slot tool, you can specify that the slot is normal to the sheet even if .hi all, is it possible to simulate sheet metal bending, forming, drawing and similar operations with solidworks simulation. 1)Is it possible to find formability of the sheet, 2)wheather sheet can hold the force? 3) or is it going to tear out?

Using Forming Tools with Sheet Metal. Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. Sheet Metal Parts. Multibody Sheet Metal Parts. SOLIDWORKS multibody part functionality lets you work with several bodies in one part to create .Using Forming Tools with Sheet Metal. Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. Sheet Metal Parts. Multibody Sheet Metal Parts. SOLIDWORKS multibody part functionality lets you work with several bodies in one part to create .Using Forming Tools with Sheet Metal: Sheet Metal Parts: Multibody Sheet Metal Parts: Using Sheet Metal Bend Parameters . you can flatten the part as sheet metal. SOLIDWORKS supports straight cuts only, not slanted cuts. To create rips in cylindrical or conical models: . Version: SOLIDWORKS 2024 SP05 To disable help from within .Using Forming Tools with Sheet Metal. Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. Sheet Metal Parts. Multibody Sheet Metal Parts. SOLIDWORKS multibody part functionality lets you work with several bodies in one part to create .

Before you apply forming tools to sheet metal parts, in the Design Library you must right-click the folder that contains the forming tools and select Forming Tools Folder to designate its contents as forming tools. This applies to forming tools that are part .Before you apply forming tools to sheet metal parts, in the Design Library you must right-click the folder that contains the forming tools and select Forming Tools Folder to designate its contents as forming tools. This applies to forming tools that are part .Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .

Using Forming Tools with Sheet Metal. Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. Converting Solid Bodies to Sheet Metal. Sheet Metal Parts. Multibody Sheet Metal Parts. SolidWorks multibody part functionality lets you work with .Simulation: Sketching: SLDXML Data Exchange: Toolbox: SOLIDWORKS Utilities: . If the forming tool has radii that are pushed into the sheet metal body, then the forming tool will fail when the concave radius is smaller than the material thickness. In this case the radius that gets pushed into the sheet metal body becomes negative and forces . Full Tutorial of Sheet Metal V Bending Animation in SolidworksDie and Punch Parts Design, Assembly and Animation Steps are Shown in detail. Follow the steps .

Figure 1: Forming a flap into a sheet metal part. Validate on the Fly. Forming simulation tools on the 3DEXPERIENCE platform recreate manufacturing processes virtually to check for potential problems such as thinning, wrinkling, or cracking. This enables you to adapt on the fly during development, which often eliminates the need for multiple .Open a sheet metal part, and browse to the forming tools folder in the Design Library.; Right-click the folder and click Forming Tools Folder.If Forming Tools Folder is already selected, omit this step. When asked if you want all subfolders to be marked as forming tools folders, click Yes.Using Forming Tools with Sheet Metal. Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. Sheet Metal Parts. Multibody Sheet Metal Parts. SOLIDWORKS multibody part functionality lets you work with several bodies in one part to create .Today the metal forming industry is making increasing use of simulation to evaluate the performing of dies, processes and blanks prior to building try-out tooling. Finite element analysis (FEA) is the most common method of simulating sheet metal forming operations to determine whether a proposed design will produce parts free of defects such as fracture or wrinkling.

cantex 1-gang plastic adjustable electrical box extender

How to carry sheet metal simulation and analysis in solidowrks, learn all this in this video tutorial.How to define sheet metal thickness?How to evaluate str.

Before you apply forming tools to sheet metal parts, in the Design Library you must right-click the folder that contains the forming tools and select Forming Tools Folder to designate its contents as forming tools. This applies to forming tools that are part files (*.SLDPRT), not Form Tool (*.SLDFTP) files.

Using Forming Tools with Sheet Metal. Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. Sheet Metal Parts. Multibody Sheet Metal Parts. SOLIDWORKS multibody part functionality lets you work with several bodies in one part to create .> Sheet Metal > Using Forming Tools with Sheet Metal > Replacing Forming Tools. SOLIDWORKS Connected Help | Print . Simulation: Sketching: SLDXML Data Exchange: Toolbox: SOLIDWORKS Utilities: . EXPERIENCE SOLIDWORKS) 2025 SP0 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS .Using Forming Tools with Sheet Metal. Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. Sheet Metal Parts. Multibody Sheet Metal Parts. SOLIDWORKS multibody part functionality lets you work with several bodies in one part to create .

solidworks sheet metal forming

canvas electric box

solidworks sheet metal add in

By accurately sizing your junction box, you ensure compliance with safety standards, prevent potential electrical issues, and optimize space usage. The calculator takes into account .

sheet metal forming simulation solidworks|solidworks forming simulation