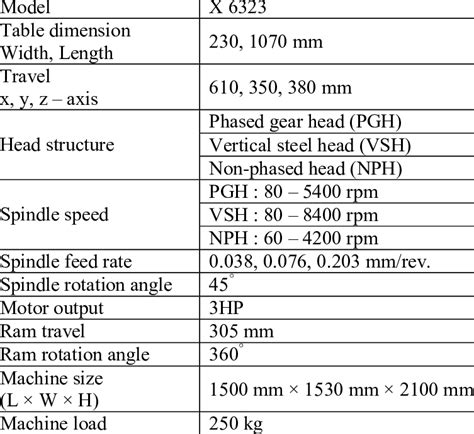

3 axis cnc milling machine diagram This machine is referred to as a CNC TU 3A machine because it is a milling machine and has three main axes, namely: x, y, and z, like Figure 2 below. 3-axis CNC milling machines. The knuckle is two big, heavy pieces of steel which connect two huge, massive train cars, and here's the dangerous part: they move around. There is a gap between the two halves of the .

0 · specifications of cnc milling machine

1 · small 3 axis cnc mill

2 · datron cnc price list

3 · axis identification in cnc machine

4 · 3 axis vertical milling machine

5 · 3 axis manual milling machine

6 · 3 axis cnc table

7 · 3 axis cnc machine price

Overall, the purpose of a junction box is to provide a safe and organized space for electrical connections. It protects the connections from external factors and promotes efficient wiring systems that are both reliable .

Download scientific diagram | Electrical diagram of the 3-axis CNC milling machine. from publication: Fuxxy Logic Control System of Three-Axis CNC Milling Machine | Milling.In a 3 axis milling machine, the spindle moves on the X, Y and Z axis. Therefore the digital models of the parts should be arranged according to the working principle of machines.

Our three-axis CNC machine tool is committed to miniaturization and portability, which enables people who do not know the CNC machine tool very well, but also can transfer out things they .Figure 1 shows the experimental model of the 3-axis CNC milling machine [3]. To extend the functionality of the machine and to prolong the life of the cutting tool, the authors.This machine is referred to as a CNC TU 3A machine because it is a milling machine and has three main axes, namely: x, y, and z, like Figure 2 below. 3-axis CNC milling machines.3 Axis CNC Milling Machine: For lots of projects a CNC milling machine is necessary for good and fast results. After some research about current available machines I came to the conclusion that all machines in a price frame of up to .

specifications of cnc milling machine

The vertical milling machine is a 3-axis milling machine. It has a table acting as a work surface and spindle. In vertical milling machines, as the name suggests, the spindle axis has a vertical orientation.

cnc machining for industrial equipment industry

A 3-axis CNC machine, such as a lathe, mill, or machine tool center, moves its tool (whether it’s a cutter, drill, or mill) along the X (left to right), Y (front to back), and Z (up and down) axes. More specifically, it can move .How to Wire an Arduino-based 3-axis CNC Machine: I've seen a number of tutorials about how to build the platform for a 3-axis CNC milling machine. I have not seen anyone tackle the tricky subject of the electronics.

This video is a welcome and brief summary of what to expect from the three axis CNC mill manual programming course.Download scientific diagram | Electrical diagram of the 3-axis CNC milling machine. from publication: Fuxxy Logic Control System of Three-Axis CNC Milling Machine | Milling.In a 3 axis milling machine, the spindle moves on the X, Y and Z axis. Therefore the digital models of the parts should be arranged according to the working principle of machines.

Our three-axis CNC machine tool is committed to miniaturization and portability, which enables people who do not know the CNC machine tool very well, but also can transfer out things they like.Figure 1 shows the experimental model of the 3-axis CNC milling machine [3]. To extend the functionality of the machine and to prolong the life of the cutting tool, the authors.This machine is referred to as a CNC TU 3A machine because it is a milling machine and has three main axes, namely: x, y, and z, like Figure 2 below. 3-axis CNC milling machines.3 Axis CNC Milling Machine: For lots of projects a CNC milling machine is necessary for good and fast results. After some research about current available machines I came to the conclusion that all machines in a price frame of up to 2000€ can not fulfill my needs regarding wor.

The vertical milling machine is a 3-axis milling machine. It has a table acting as a work surface and spindle. In vertical milling machines, as the name suggests, the spindle axis has a vertical orientation. A 3-axis CNC machine, such as a lathe, mill, or machine tool center, moves its tool (whether it’s a cutter, drill, or mill) along the X (left to right), Y (front to back), and Z (up and down) axes. More specifically, it can move either horizontally (X-Y axes) or vertically (Z axis) to control the cutting depth.How to Wire an Arduino-based 3-axis CNC Machine: I've seen a number of tutorials about how to build the platform for a 3-axis CNC milling machine. I have not seen anyone tackle the tricky subject of the electronics.

This video is a welcome and brief summary of what to expect from the three axis CNC mill manual programming course.Download scientific diagram | Electrical diagram of the 3-axis CNC milling machine. from publication: Fuxxy Logic Control System of Three-Axis CNC Milling Machine | Milling.

In a 3 axis milling machine, the spindle moves on the X, Y and Z axis. Therefore the digital models of the parts should be arranged according to the working principle of machines.Our three-axis CNC machine tool is committed to miniaturization and portability, which enables people who do not know the CNC machine tool very well, but also can transfer out things they like.Figure 1 shows the experimental model of the 3-axis CNC milling machine [3]. To extend the functionality of the machine and to prolong the life of the cutting tool, the authors.This machine is referred to as a CNC TU 3A machine because it is a milling machine and has three main axes, namely: x, y, and z, like Figure 2 below. 3-axis CNC milling machines.

3 Axis CNC Milling Machine: For lots of projects a CNC milling machine is necessary for good and fast results. After some research about current available machines I came to the conclusion that all machines in a price frame of up to 2000€ can not fulfill my needs regarding wor.The vertical milling machine is a 3-axis milling machine. It has a table acting as a work surface and spindle. In vertical milling machines, as the name suggests, the spindle axis has a vertical orientation.

A 3-axis CNC machine, such as a lathe, mill, or machine tool center, moves its tool (whether it’s a cutter, drill, or mill) along the X (left to right), Y (front to back), and Z (up and down) axes. More specifically, it can move either horizontally (X-Y axes) or vertically (Z axis) to control the cutting depth.How to Wire an Arduino-based 3-axis CNC Machine: I've seen a number of tutorials about how to build the platform for a 3-axis CNC milling machine. I have not seen anyone tackle the tricky subject of the electronics.

What Is a Distribution Box? The distribution box is a small box that comes after the septic tank but before the drain field. They're usually made of either plastic or concrete, and they have several openings on different sides where the drain field lines connect to the box.

3 axis cnc milling machine diagram|specifications of cnc milling machine