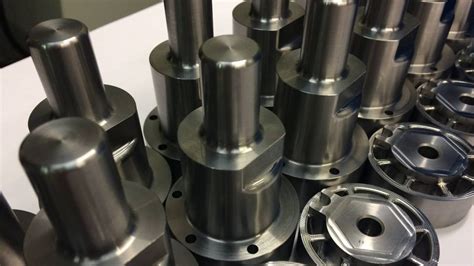

cnc machine material Industry professionals employ a wide range of materials in CNC machining operations to suit different product and project specifications. Some of the most commonly .

Sigma's weatherproof closure plugs help keep moisture from the electrical wiring by closing unused holes in weatherproof boxes, extension rings or covers. In a world that runs largely on electricity, junction boxes are crucial to protecting electrical wiring systems.

0 · cnc milling materials

1 · cnc mill low carbon steel

2 · cnc materials guide

3 · cnc material list

4 · cnc low carbon steel tool

5 · cnc carbon steel table

6 · cnc carbon steel sheet

7 · best mild steel for machining

Protect your outdoor connections with this weatherproof junction box - an IP66-rated moulded enclosure made from high-impact and self-extinguishing ABS. The box includes seven 20mm screwed entry knockouts and a 5-pole 20A connector.

cnc milling materials

This comprehensive guide compares the 25 most common materials used in CNC machining and helps you choose the right one for your application. CNC machining has become a staple for a wide array of disciplines that need specialized parts manufactured for their projects. CNC materials have expanded to meet the demands of consumers, engineers, contractors and .

This comprehensive guide discusses the CNC machining material selection process, detailing the common materials and their properties, factors to consider, and more.

wholesale custom cnc parts

CNC machining stands as a cornerstone in modern manufacturing. Its ability to shape a vast array of materials into precise parts makes it indispensable. This process adapts seamlessly to .In this comprehensive guide, I’m going to walk you through everything you need to know about CNC machining materials. We’ll explore the different types of materials, their characteristics, . Industry professionals employ a wide range of materials in CNC machining operations to suit different product and project specifications. Some of the most commonly .Identifying Commonly Used Machining Materials. Over the years, our engineers have identified selected materials that work well for machining processes and that have been popular choices among our customers. For metals, these include .

These CNC machining materials range from conventional plastic and metals to wood, ceramics, and composites. In this article, we’d focus more on plastic and metal machining materials as they have more diverse uses across . How To Choose The Right CNC Machining Materials? Our Step-by-Step Guidelines. The above information can help inform your decision about what material will best suit your application, bearing in mind that in many .

This comprehensive guide compares the 25 most common materials used in CNC machining and helps you choose the right one for your application. CNC machining has become a staple for a wide array of disciplines that need specialized parts manufactured for their projects. CNC materials have expanded to meet the demands of consumers, engineers, contractors and other fields to create solutions for very specific applications.

Discover the array of materials suitable for CNC machining in our extensive guide, covering everything from metals to composites you can CNC. This comprehensive guide discusses the CNC machining material selection process, detailing the common materials and their properties, factors to consider, and more.CNC machining stands as a cornerstone in modern manufacturing. Its ability to shape a vast array of materials into precise parts makes it indispensable. This process adapts seamlessly to metals, plastics, and even composites. Let's delve into how CNC machining flexes its versatility across different materials.In this comprehensive guide, I’m going to walk you through everything you need to know about CNC machining materials. We’ll explore the different types of materials, their characteristics, and the best practices for selecting and using them.

Industry professionals employ a wide range of materials in CNC machining operations to suit different product and project specifications. Some of the most commonly used materials include: Aluminum. One of the most common and easy to machine metals available, aluminum is a highly versatile and cost-effective option for CNC machining projects.Identifying Commonly Used Machining Materials. Over the years, our engineers have identified selected materials that work well for machining processes and that have been popular choices among our customers. For metals, these include aluminum, brass, .

These CNC machining materials range from conventional plastic and metals to wood, ceramics, and composites. In this article, we’d focus more on plastic and metal machining materials as they have more diverse uses across a variety of industries.

How To Choose The Right CNC Machining Materials? Our Step-by-Step Guidelines. The above information can help inform your decision about what material will best suit your application, bearing in mind that in many cases more than one choice will work just fine.

This comprehensive guide compares the 25 most common materials used in CNC machining and helps you choose the right one for your application. CNC machining has become a staple for a wide array of disciplines that need specialized parts manufactured for their projects. CNC materials have expanded to meet the demands of consumers, engineers, contractors and other fields to create solutions for very specific applications. Discover the array of materials suitable for CNC machining in our extensive guide, covering everything from metals to composites you can CNC. This comprehensive guide discusses the CNC machining material selection process, detailing the common materials and their properties, factors to consider, and more.

CNC machining stands as a cornerstone in modern manufacturing. Its ability to shape a vast array of materials into precise parts makes it indispensable. This process adapts seamlessly to metals, plastics, and even composites. Let's delve into how CNC machining flexes its versatility across different materials.In this comprehensive guide, I’m going to walk you through everything you need to know about CNC machining materials. We’ll explore the different types of materials, their characteristics, and the best practices for selecting and using them. Industry professionals employ a wide range of materials in CNC machining operations to suit different product and project specifications. Some of the most commonly used materials include: Aluminum. One of the most common and easy to machine metals available, aluminum is a highly versatile and cost-effective option for CNC machining projects.

Identifying Commonly Used Machining Materials. Over the years, our engineers have identified selected materials that work well for machining processes and that have been popular choices among our customers. For metals, these include aluminum, brass, . These CNC machining materials range from conventional plastic and metals to wood, ceramics, and composites. In this article, we’d focus more on plastic and metal machining materials as they have more diverse uses across a variety of industries.

wholesale machine parts precision cnc

Withstand the harsh elements of the outdoors with Weatherproof Boxes from Graybar. Protect your outlets from moisture and rain to ensure safe operation. We have a wide variety of weatherproof box covers and accessories. In addition, choose from various FS/FD boxes and covers. Find the right solution for powering your equipment outdoors.

cnc machine material|cnc materials guide