conventional processes in sheet metal forming metal forming processes, which are based upon older technologies. In this case modifications have been made to traditional forming methods such as conventional spinning and shear forming. Truck tool boxes are typically constructed of four different materials: aluminum, steel, stainless steel, and heavy-duty plastic. Let's quickly walk through the pros and cons of each one. Most truck tool boxes are made from aluminum and .

0 · sheet metal working process pdf

1 · sheet metal stamping process pdf

2 · sheet metal processes pdf

3 · sheet metal forming process pdf

4 · sheet metal forming press dies

5 · sheet metal forming by hand

6 · sheet metal bending process pdf

7 · bulk deformation vs sheet metal forming

In contrast, a fully framed shower door has both glass doors surrounded by metal framing — including the middle and vertical frame. With a semi-frameless unit, the entire inside of the frame is clear or opaque glass — giving it a more modern and stylish look.

sheet metal working process pdf

cnc machine white background

sheet metal stamping process pdf

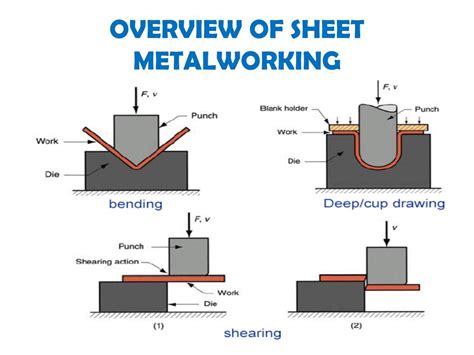

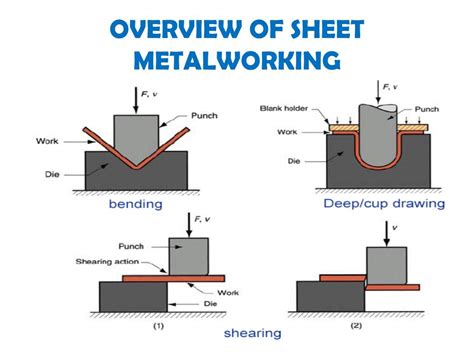

The main processes of sheet metal forming are the stretch forming, deep drawing, or in general a combination of both. During stretch forming, the sheet material will be shaped by the punch .metal forming processes, which are based upon older technologies. In this case modifications have been made to traditional forming methods such as conventional spinning and shear forming.This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. It provides rigorous detail on the three all-important groups of metal-forming processes: bulk-metal .

A comparison of traditional and modern forming methods is presented here in an attempt to illustrate the evolution of different incremental sheet metal forming techniques. Emphasis is . This paper aims at scattering light on the recent research and developments in the sheet metal forming processes over the last two decades. Most of the literature available on .This study is intended to summarize recent development trends in both the numerical and experimental fields of conventional deep-drawing, spinning, flexible-die forming, electromagnetic forming and computer-controlled forming .

In a sheet forming process, a thin piece of metal sheet, commonly referred to as the blank, is bent or stretched by tools into a desired shape without excessive thinning, tearing, or wrinkling. .Metal forming process in which an axially symmetric part is gradually shaped over a rotating mandrel using a rounded tool or roller Conventional spinning: (1) setup at start of process; (2) .

cnc machine with atc benchtop

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different ..describe different forming processes, when they might be used, and compare their production rates, costs and environmental impacts .calculate forming forces, predict part defects (tearing, wrinkling, dimensional inaccuracy), and propose solutions .explain current developments: opportunities and challenges ObjectivesThe main processes of sheet metal forming are the stretch forming, deep drawing, or in general a combination of both. During stretch forming, the sheet material will be shaped by the punch but squeezed between the drawing die and the blank holder.metal forming processes, which are based upon older technologies. In this case modifications have been made to traditional forming methods such as conventional spinning and shear forming.

This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. It provides rigorous detail on the three all-important groups of metal-forming processes: bulk-metal forming, sheet-metal forming, and sheet-bulk-metal forming.A comparison of traditional and modern forming methods is presented here in an attempt to illustrate the evolution of different incremental sheet metal forming techniques. Emphasis is placed on conventional spinning, shear forming and modern computer-controlled forming methods that are currently being studied. This paper aims at scattering light on the recent research and developments in the sheet metal forming processes over the last two decades. Most of the literature available on sheet metal forming focuses on the parameters that influence the .

This study is intended to summarize recent development trends in both the numerical and experimental fields of conventional deep-drawing, spinning, flexible-die forming, electromagnetic forming and computer-controlled forming methods like incremental sheet forming.

In a sheet forming process, a thin piece of metal sheet, commonly referred to as the blank, is bent or stretched by tools into a desired shape without excessive thinning, tearing, or wrinkling. Here we present a brief introduction to several sheet forming processes widely used in industry.

Metal forming process in which an axially symmetric part is gradually shaped over a rotating mandrel using a rounded tool or roller Conventional spinning: (1) setup at start of process; (2) during spinning; and (3) completion of process

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different processes and equipment, which we’ll cover a .

.describe different forming processes, when they might be used, and compare their production rates, costs and environmental impacts .calculate forming forces, predict part defects (tearing, wrinkling, dimensional inaccuracy), and propose solutions .explain current developments: opportunities and challenges ObjectivesThe main processes of sheet metal forming are the stretch forming, deep drawing, or in general a combination of both. During stretch forming, the sheet material will be shaped by the punch but squeezed between the drawing die and the blank holder.metal forming processes, which are based upon older technologies. In this case modifications have been made to traditional forming methods such as conventional spinning and shear forming.This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. It provides rigorous detail on the three all-important groups of metal-forming processes: bulk-metal forming, sheet-metal forming, and sheet-bulk-metal forming.

A comparison of traditional and modern forming methods is presented here in an attempt to illustrate the evolution of different incremental sheet metal forming techniques. Emphasis is placed on conventional spinning, shear forming and modern computer-controlled forming methods that are currently being studied.

This paper aims at scattering light on the recent research and developments in the sheet metal forming processes over the last two decades. Most of the literature available on sheet metal forming focuses on the parameters that influence the .This study is intended to summarize recent development trends in both the numerical and experimental fields of conventional deep-drawing, spinning, flexible-die forming, electromagnetic forming and computer-controlled forming methods like incremental sheet forming.In a sheet forming process, a thin piece of metal sheet, commonly referred to as the blank, is bent or stretched by tools into a desired shape without excessive thinning, tearing, or wrinkling. Here we present a brief introduction to several sheet forming processes widely used in industry.

Metal forming process in which an axially symmetric part is gradually shaped over a rotating mandrel using a rounded tool or roller Conventional spinning: (1) setup at start of process; (2) during spinning; and (3) completion of process

I’ve noticed lately that theu use some sort of metal device to rub on the face. I assume it is cold and absorbs heat faster than other things. Yep. It’s called an endswell, pronounced “end swell.” A little pressure and cold keeps down swelling that could cause a mouse to rise or an eye to swell shut.

conventional processes in sheet metal forming|sheet metal working process pdf