in which process components from sheet metal are manufactured “Hybrid” broadly refers to the combination of two or more characteristics, and the application of hybrid strategies in the field of modern manufacturing technology mainly involves three aspects: materials, components, and processes [16].Hybrid materials are designed to push the limits of conventional materials in terms of performance to obtain novel design possibilities, . $254.99

0 · types of sheet metal fabrication

1 · sheet metal manufacturing process types

2 · sheet metal manufacturing guide

3 · sheet metal fabrication guide

4 · sheet metal fabrication capabilities

5 · sheet metal diagram fabrication

6 · sheet metal design and fabrication

7 · material used in sheet metal

Ex-Proof ZONE I junction box. Tuna JB-Ex model can be connected to loadcell with 2-4-6-8-10 output. It is suitable for environments where easily flammable chemicals, gases or petroleum products are present with its flameproof, .

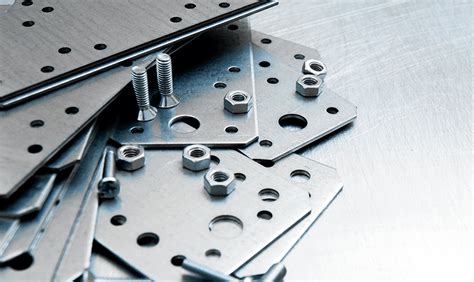

The family of manufacturing processes used to create sheet metal components encompasses a diverse range of techniques, each tailored to achieve specific shapes, sizes, and features with precision and efficiency. The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, .

The manufacturing & design guide. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material .

jt sheet metal

“Hybrid” broadly refers to the combination of two or more characteristics, and the application of hybrid strategies in the field of modern manufacturing technology mainly involves three aspects: materials, components, and processes [16].Hybrid materials are designed to push the limits of conventional materials in terms of performance to obtain novel design possibilities, . As the global demand for custom metal parts and sheet metal fabrication services increases, manufacturers have a great opportunity for improved metal parts manufacturing business. The covid-19 may have slowed .Updated 16 August 2023. Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods.The completion of a product usually comprises of many steps – from cutting and .Explanation: Sheet metal forming is a process which uses ductile materials like aluminium or low carbon steel to form lightweight products with versatile features. Car bodies are mainly manufactured by sheet metal forming by performing operations like shearing, slitting, cutting, or sawing of thin metal plates.

First, aerospace sheet metal fabrication involves manipulating sheet metal to make aircraft parts and components. Recently, many aircraft manufacturers, such as Lockheed Martin, General Electric, Airbus, Leonardo, Boeing, and Raytheon, use different sheet metal fabrication techniques. It is due to:

types of sheet metal fabrication

Sheet metal forming is a process used in many industries to make metal parts from thin metal sheets. It’s actually one of Xometry's most popular manufacturing methods. Our customers use the Xometry Instant Quoting Engine® to get automatic quotes on everything from simple brackets to aircraft parts and sheet metal assemblies.Sheet Metal laser cutting. You may use the laser cutting method to cut a variety of materials, including steel and aluminium sheets, as well as three-dimensional objects like profiles and tubes.. More than two decades ago, technology launched laser cutting as an industrial technique. The study aims at a high-energy, highly focused laser beam at a workpiece during the cutting .

Ever wondered what goes into shaping the metal components we use daily? The answer lies in the meticulous sheet metal fabrication process. Understanding this process is crucial for businesses and professionals in the metal industry. The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves .Welcome to the definitive guide on sheet metal processing, an essential pillar in a multitude of global industries. From our daily commute vehicles to our indispensable household appliances, countless products we interact with everyday come to life through the intricate choreography of sheet metal manufacturing processes. Sheet metal processing is a method that manipulates .

The Process of Sheet Metal Housing Manufacturing. The journey from a raw sheet of metal to a functional housing unit involves meticulous planning, cutting-edge technology, and skilled craftsmanship. . These precision bends ensure the housing will fit perfectly with its intended components. After the bending process, the housing goes through .

Question: Q5. Select the correct answer (10 points) 1. Which of the following components are manufactured by the sheet metal forming process a. engine blocks b. connecting rods c. electric wires d. car bodies 2. Which of the following process is not the type of metal forming process a. extrusion b. injection molding c. forging d. drawing 3. Sheet metal fabrication is a versatile manufacturing process with a wide range of applications across various industries. Its ability to produce durable, customizable, and cost-effective parts has positioned it as a cornerstone of the sheet metal industry, impacting diverse sectors from automotive to consumer goods.

There are two main ways that sheet metal components can be manufactured: bending or stamping. Both involve taking a flat piece of thin metal and forming it into a final shape, but the process by which they do this varies immensely. . Turret punches, on the other hand, use a punch and die to create standard cut-outs in the metal. This process .

Its been years since we are manufacturing and supplying sheet metal parts and other metal components around Inida. We have an extensive array of capabilities and equipment, punching, forming, bending, stamping, welding, and machining and can provide products with complete all assembly precisely. Fig. 1: Sheet Metal Bending Process at Komacut. Joining Methods. After the cutting and shaping stages, the joining process involves bringing together individual sheet metal pieces into a unified structure. . Sheet metal machines are widely used in various manufacturing industries for shaping, cutting, and forming sheet metal into different components. Some of the industries that extensively utilize sheet metal machines include light industries such as electrical and medical equipment, all the way up to heavy industries such as automotive, rail, oil and gas, as well as .

Below, we’ll explain the most common metal manufacturing processes:. Cutting. The first step in the sheet metal fabrication process is cutting, which is where the fabricators will slice the raw materials into the parts needed to complete a project. Getting precise cuts is critical. Even the odd millimetre in the wrong direction can throw the finished product out of alignment. Sheet Metal Mounting Brackets, how they are manufactured and their uses. In the realm of industrial design and construction, the unsung heroes known as sheet metal mounting brackets play a crucial role in providing stability and support. These unassuming components are the backbone of many structures, ensuring that everything from shelves to heavy machinery .

judas priest 50 heavy metal years box set

Sheet metal enclosures are protective or supportive structures fabricated from various metals to house, secure, or support electrical, electronic, or mechanical components. These enclosures play a critical role in numerous industries by protecting sensitive equipment from environmental factors, electromagnetic interference, and mechanical impacts. Bending is a fundamental sheet metal forming process that transforms 2D flat parts into 3D components with precise angles and contours. . Assembly is the critical final stage in manufacturing where multiple components are precisely combined to create a finished product. This process requires meticulous attention to detail and a comprehensive .Sheet Metal Manufacturing Processes: Sheet metal manufacturing encompasses the fabrication of sheet metal components through cutting, bending, and shaping thin metal sheets into precise configurations and dimensions. This process commonly involves employing coating, cutting, bending, and assembly methodologies. Sheet metal forming, a versatile manufacturing process that transforms flat metal sheets into complex and intricate shapes, is a crucial aspect of modern engineering. This article, written by experts in the field of sheet metal forming, provides an in-depth overview of the process, its types of processes, materials used, and the tools and .

Piercing – The usual punching procedure where a cylindrical punch punctures a hole in the sheet. Slotting – A punching technique that creates rectangular perforations in the sheet. At times known as piercing irrespective of the different shape. Perforating – Punching an adjacent sequence of a great number of apertures in one operation. Notching – Punching the .We manufacture a wide range of Sheet Metal components for Electrical, Switchgear & Engineering Industries. . Testing & Certification Process. Each spring manufactured goes through a series of rigorous tests conducted on in house testing facilities such as Computerized UTS Testing, Profile Projector amongst others. .

sheet metal manufacturing process types

sheet metal manufacturing guide

Reliable and durable sheet metal assemblies rely heavily on sheet metal parts fabricated with precision and efficiency in mind. Streamlining the process of sheet metal assembly, where accuracy and repeatability foster the fabrication of intricate and complex sheet metal components, is essential when serving leading manufacturers in today’s most important .The family of manufacturing processes used to create sheet metal components encompasses a diverse range of techniques, each tailored to achieve specific shapes, sizes, and features with precision and efficiency. . Shearing is a fundamental manufacturing process within sheet metal fabrication, serving as a primary method for cutting and .Sheet Metal Components. We offer the sheet metal manufacturing solution, from single part or subassembly manufacture to turnkey solutions. Utilising the latest sheet metal manufacturing technology we offer metal bending, welding, spot welding, powder coating and induction brazing services under quality environment, metal stamping, metal punching, metal inserting.

john deere m sheet metal

sheet metal fabrication guide

$9.99

in which process components from sheet metal are manufactured|sheet metal fabrication capabilities