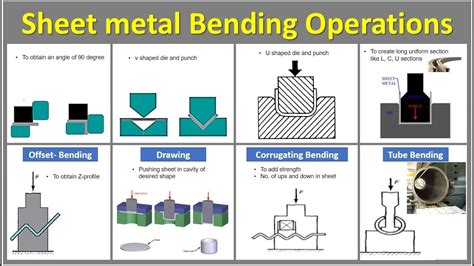

bending sheet metal box Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc. CNC stands for Computer Numerical Control, which refers to the computerized operation of machining tools used in manufacturing. CNC machines operate using pre-programmed software and codes, which tell each machine the .

0 · types of bending sheet metal

1 · sheet metal bending standards

2 · sheet metal bending near me

3 · sheet metal bending guidelines

4 · sheet metal bending chart

5 · problems with sheet metal bending

6 · bending sheet metal by hand

7 · bending galvanized sheet metal

A septic tank’s distribution box (or D-box) is a container (typically concrete) that receives the septic tank effluent and re-distributes it into the network of attached drain fields and pipes. To put it simply, its job is to evenly distribute the wastewater into the leach field.

Once the hems have been made the next step is to bend your metal into a box. You will be working with a sheet metal brake to complete this step. The goal here is to clamp your brake .A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal .

It is also possible to bend and flatten a hem, to form a radius, and to bend a zig-zag. The standard procedure for making a simple bend in sheet metal using a hand brake . Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc. Video tutorial includes cutting the sheetmetal template and bending the pieces on my 24" Grizzly Box & Pan brake. .more. Creating a 22 gauge sheetmetal box from scratch.

Once the hems have been made the next step is to bend your metal into a box. You will be working with a sheet metal brake to complete this step. The goal here is to clamp your brake teeth right on your lines. If your line is clamped down at an angle to your brake teeth, you will bend your metal at an angle and your box will not come out as you .A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal shears, box brakes, pop-rivets, and so on. We're not going to touch upon bend radii or bend allowances, but these.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.

It is also possible to bend and flatten a hem, to form a radius, and to bend a zig-zag. The standard procedure for making a simple bend in sheet metal using a hand brake machine is as follows: 1. Insert sheet metal under clamping bar. 2. Adjust clamping handle cam for metal thickness. 3. Measure and position the sheet metal edge the correct . Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc.

types of bending sheet metal

heavy metal box subscription

How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.--.Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend.

How do I bend and form the sheet metal for the box? Use a metal brake to bend the edges of the sheet metal to the desired angle. Make sure to use the appropriate tooling and settings for the thickness of the sheet metal.In this plan, we’ll show you how to build and use a simple bending brake like you see here. It makes crisp, clean bends on sheet metal (up to 22 ga.) for great-looking results. It’s made from a few pieces of hardwood to form the base and hinged handle. Video tutorial includes cutting the sheetmetal template and bending the pieces on my 24" Grizzly Box & Pan brake. .more. Creating a 22 gauge sheetmetal box from scratch.

Once the hems have been made the next step is to bend your metal into a box. You will be working with a sheet metal brake to complete this step. The goal here is to clamp your brake teeth right on your lines. If your line is clamped down at an angle to your brake teeth, you will bend your metal at an angle and your box will not come out as you .A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal shears, box brakes, pop-rivets, and so on. We're not going to touch upon bend radii or bend allowances, but these.

heavy metal fabrication supplier

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. It is also possible to bend and flatten a hem, to form a radius, and to bend a zig-zag. The standard procedure for making a simple bend in sheet metal using a hand brake machine is as follows: 1. Insert sheet metal under clamping bar. 2. Adjust clamping handle cam for metal thickness. 3. Measure and position the sheet metal edge the correct . Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc. How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.--.

Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. How do I bend and form the sheet metal for the box? Use a metal brake to bend the edges of the sheet metal to the desired angle. Make sure to use the appropriate tooling and settings for the thickness of the sheet metal.

sheet metal bending standards

heavy metal sheet music

Following are some points that make us think about dc power distribution. Advancements in Power electronics have made it possible to transform DC voltage levels and conversion between AC and DC efficiently. It is now possible to replace existing AC distribution network with DC distribution network.

bending sheet metal box|bending sheet metal by hand