benefits of sheet metal fabrication What Are the Benefits of Sheet Metal Forming? Unlike competing alternatives such as machining and casting, sheet fabrication allows the cost-effective, flexible, and rapid production of metal components. Discover the step-by-step process of fabricating aluminium windows and doors, including the planning, build, and quality control stages. Get in touch 01425 205465The base of the window has a thin (about 1/4") piece of metal jutting out of the buttom that's 2" high in the interior and 1.5" high in the exterior. This means I .

0 · sheet metal uses

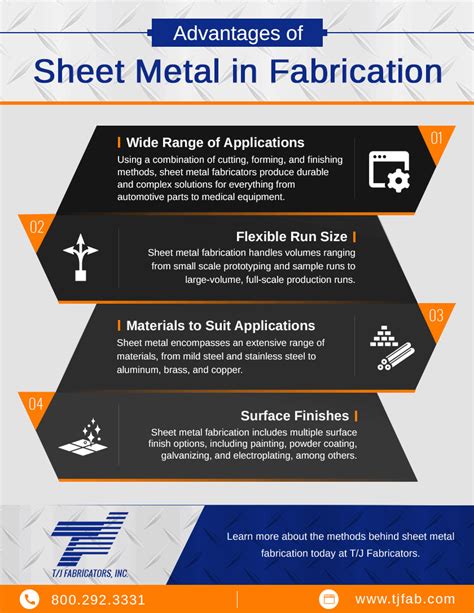

1 · sheet metal manufacturing advantages

2 · sheet metal fabrication types

3 · sheet metal fabrication techniques

4 · sheet metal fabrication process

5 · sheet metal fabrication

6 · sheet metal design advantages

7 · advantages of sheet metal

$49.98

Sheet metal fabrication allows for great design flexibility. Sheet metal can be easily cut, bent, and shaped into complex forms, offering designers the freedom to create parts with intricate geometries, creating customized and . Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a product usually comprises of many steps – from cutting and bending to .

From small brackets and enclosures to large machinery and structures, sheet metal fabrication is used across industries for its many benefits. In this comprehensive guide, we will explore the advantages of sheet metal . What Are the Benefits of Sheet Metal Forming? Unlike competing alternatives such as machining and casting, sheet fabrication allows the cost-effective, flexible, and rapid production of metal components.Sheet metal fabrication is a manufacturing technique that involves making products from flat metal sheets. As a result, you can fabricate sheet metal using different methods involving advanced .

Sheet metal fabrication is an all-around cost-effective manufacturing method. First off, the setup cost for most projects is low, as you don’t need any special molds or equipment. Next, the raw materials- sheet metal- are relatively easy and . Sheet metal is strong and durable, and sheet metal parts are often able to withstand greater pressure and heat than those made with plastic. In addition to this, aluminum, stainless steel, or surface-treated steel are all .The Benefits of Sheet Metal Fabrication. Sheet metal fabrication offers several key advantages for manufacturers and industries: Precision and Accuracy: Modern sheet metal fabrication techniques enable the creation of intricate and .

There are numerous benefits and advantages of using sheet metal fabrication techniques. Strength and durability: Sheet metal parts are resistant to pressure, corrosion, heat, moisture, sun and wear and tear, making them a .What are the benefits of sheet metal fabrication? High-precision parts; Custom-built designs; High-capacity production; Durable materials; Modern finish . Sheet metal fabrication is one of the most cost-effective options for fashioning different parts and goods out of various metals. Sheet metal fabrication allows for great design flexibility. Sheet metal can be easily cut, bent, and shaped into complex forms, offering designers the freedom to create parts with intricate geometries, creating customized and aesthetically pleasing components.

Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a product usually comprises of many steps – from cutting and bending to surface treatment and assembling.

sheet metal uses

From small brackets and enclosures to large machinery and structures, sheet metal fabrication is used across industries for its many benefits. In this comprehensive guide, we will explore the advantages of sheet metal fabrication and how it can help you achieve your manufacturing goals. What Are the Benefits of Sheet Metal Forming? Unlike competing alternatives such as machining and casting, sheet fabrication allows the cost-effective, flexible, and rapid production of metal components.Sheet metal fabrication is a manufacturing technique that involves making products from flat metal sheets. As a result, you can fabricate sheet metal using different methods involving advanced machinery to form, bend, cut, and assemble metal into any preferred shape.Sheet metal fabrication is an all-around cost-effective manufacturing method. First off, the setup cost for most projects is low, as you don’t need any special molds or equipment. Next, the raw materials- sheet metal- are relatively easy and cheap to source, transport, and work with.

Sheet metal is strong and durable, and sheet metal parts are often able to withstand greater pressure and heat than those made with plastic. In addition to this, aluminum, stainless steel, or surface-treated steel are all resistant to pressure, corrosion, and wear and tear.The Benefits of Sheet Metal Fabrication. Sheet metal fabrication offers several key advantages for manufacturers and industries: Precision and Accuracy: Modern sheet metal fabrication techniques enable the creation of intricate and precise metal components that adhere to exact specifications.

There are numerous benefits and advantages of using sheet metal fabrication techniques. Strength and durability: Sheet metal parts are resistant to pressure, corrosion, heat, moisture, sun and wear and tear, making them a superior choice for many projects.

What are the benefits of sheet metal fabrication? High-precision parts; Custom-built designs; High-capacity production; Durable materials; Modern finish . Sheet metal fabrication is one of the most cost-effective options for fashioning different parts and goods out of various metals. Sheet metal fabrication allows for great design flexibility. Sheet metal can be easily cut, bent, and shaped into complex forms, offering designers the freedom to create parts with intricate geometries, creating customized and aesthetically pleasing components. Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a product usually comprises of many steps – from cutting and bending to surface treatment and assembling. From small brackets and enclosures to large machinery and structures, sheet metal fabrication is used across industries for its many benefits. In this comprehensive guide, we will explore the advantages of sheet metal fabrication and how it can help you achieve your manufacturing goals.

What Are the Benefits of Sheet Metal Forming? Unlike competing alternatives such as machining and casting, sheet fabrication allows the cost-effective, flexible, and rapid production of metal components.Sheet metal fabrication is a manufacturing technique that involves making products from flat metal sheets. As a result, you can fabricate sheet metal using different methods involving advanced machinery to form, bend, cut, and assemble metal into any preferred shape.Sheet metal fabrication is an all-around cost-effective manufacturing method. First off, the setup cost for most projects is low, as you don’t need any special molds or equipment. Next, the raw materials- sheet metal- are relatively easy and cheap to source, transport, and work with. Sheet metal is strong and durable, and sheet metal parts are often able to withstand greater pressure and heat than those made with plastic. In addition to this, aluminum, stainless steel, or surface-treated steel are all resistant to pressure, corrosion, and wear and tear.

The Benefits of Sheet Metal Fabrication. Sheet metal fabrication offers several key advantages for manufacturers and industries: Precision and Accuracy: Modern sheet metal fabrication techniques enable the creation of intricate and precise metal components that adhere to exact specifications.

sheet metal manufacturing advantages

This aluminum alloy intake box hides away cables and wires to the camera and provides a secure, waterproof design. Main Features Aluminum Alloy Material with Surface Spray Treatment

benefits of sheet metal fabrication|sheet metal fabrication techniques