benefits cnc machine tending By implementing a machine tending robot to handle the loading and unloading of CNC machines, human workers can redirect their efforts toward more value-added activities. Operating autonomously, the robot can enable . Meet Danby’s ultimate space-saving 0.7 cu. ft. under the cupboard stainless-steel microwave. This microwave can be placed on the countertop or anywhere .

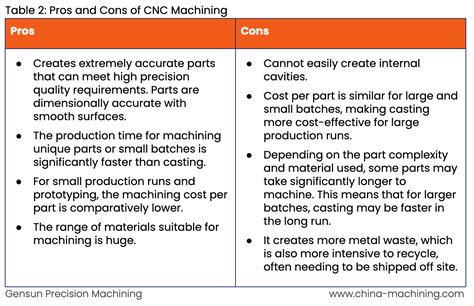

0 · pros and cons of machining

1 · disadvantages of cnc milling

2 · disadvantages of cnc

3 · cnc milling pros and cons

4 · cnc milling advantages and disadvantages

5 · cnc machining advantages and disadvantages

6 · cnc machine pros and cons

7 · cnc advantages and disadvantages

Buy electrical underground pull boxes from the Scott Electric online store.

A CNC machine tending robot is an automated system designed to load and unload parts from a CNC (Computer Numerical Control) machine, such as a milling machine, lathe, or grinding machine. These robots are typically used in manufacturing settings to increase .

Simply put, machine tending is the process of using a robot to automate the tasks associated with CNC machining. These tasks commonly include loading and unloading the workpiece, and activating various parts of .CNC robots automate machine tending, boosting machining productivity, efficiency, and quality. Let's explore their applications, benefits, challenges, and how to choose the right solution. Discover the benefits of CNC machine tending automation—boost productivity, enhance safety, and cut costs with robots running 24/7 for efficient manufacturing. By implementing a machine tending robot to handle the loading and unloading of CNC machines, human workers can redirect their efforts toward more value-added activities. Operating autonomously, the robot can enable .

Benefits: Automation in CNC machine tending optimizes scheduling and batch processing, reduces waste, enhances energy efficiency, facilitates quick changeovers, and improves .

Thanks to the continuing advancement of robotic technology, machine tending automation just keeps getting easier and easier to use. For almost all of industrial history, machine operators have had to tend CNC .Machine tending offers to make workloads easier, especially for the next generation of CNC machining. It can provide years to decades of unattended yet safe operations, magnified productivity, and multitasking.

cr legacy sheet metal works

pros and cons of machining

Robots enhance CNC machine tending by automating repetitive tasks like loading, unloading, material handling, inspection, and other operations. This improves efficiency, reduces human error, and enables machines to run .Automating CNC machine tending with robot manipulators creates a safer work environment for human workers. Factory robots are better equipped for repetitive motions, heavy lifting, and . A CNC machine tending robot is an automated system designed to load and unload parts from a CNC (Computer Numerical Control) machine, such as a milling machine, lathe, or grinding machine. These robots are typically used in manufacturing settings to increase efficiency, reduce labor costs, and improve safety. Simply put, machine tending is the process of using a robot to automate the tasks associated with CNC machining. These tasks commonly include loading and unloading the workpiece, and activating various parts of the CNC cycle. Machine tending can be a highly efficient way to manage a factory floor.

CNC robots automate machine tending, boosting machining productivity, efficiency, and quality. Let's explore their applications, benefits, challenges, and how to choose the right solution. Discover the benefits of CNC machine tending automation—boost productivity, enhance safety, and cut costs with robots running 24/7 for efficient manufacturing.

By implementing a machine tending robot to handle the loading and unloading of CNC machines, human workers can redirect their efforts toward more value-added activities. Operating autonomously, the robot can enable lights-out production, optimize machine output, and slash labor costs.Benefits: Automation in CNC machine tending optimizes scheduling and batch processing, reduces waste, enhances energy efficiency, facilitates quick changeovers, and improves safety by assigning hazardous tasks to robots.

Thanks to the continuing advancement of robotic technology, machine tending automation just keeps getting easier and easier to use. For almost all of industrial history, machine operators have had to tend CNC machines manually.Machine tending offers to make workloads easier, especially for the next generation of CNC machining. It can provide years to decades of unattended yet safe operations, magnified productivity, and multitasking.

Robots enhance CNC machine tending by automating repetitive tasks like loading, unloading, material handling, inspection, and other operations. This improves efficiency, reduces human error, and enables machines to run continuously, leading to increased productivity and consistency in operations.Automating CNC machine tending with robot manipulators creates a safer work environment for human workers. Factory robots are better equipped for repetitive motions, heavy lifting, and handling chemicals. A CNC machine tending robot is an automated system designed to load and unload parts from a CNC (Computer Numerical Control) machine, such as a milling machine, lathe, or grinding machine. These robots are typically used in manufacturing settings to increase efficiency, reduce labor costs, and improve safety.

Simply put, machine tending is the process of using a robot to automate the tasks associated with CNC machining. These tasks commonly include loading and unloading the workpiece, and activating various parts of the CNC cycle. Machine tending can be a highly efficient way to manage a factory floor.CNC robots automate machine tending, boosting machining productivity, efficiency, and quality. Let's explore their applications, benefits, challenges, and how to choose the right solution. Discover the benefits of CNC machine tending automation—boost productivity, enhance safety, and cut costs with robots running 24/7 for efficient manufacturing. By implementing a machine tending robot to handle the loading and unloading of CNC machines, human workers can redirect their efforts toward more value-added activities. Operating autonomously, the robot can enable lights-out production, optimize machine output, and slash labor costs.

Benefits: Automation in CNC machine tending optimizes scheduling and batch processing, reduces waste, enhances energy efficiency, facilitates quick changeovers, and improves safety by assigning hazardous tasks to robots. Thanks to the continuing advancement of robotic technology, machine tending automation just keeps getting easier and easier to use. For almost all of industrial history, machine operators have had to tend CNC machines manually.Machine tending offers to make workloads easier, especially for the next generation of CNC machining. It can provide years to decades of unattended yet safe operations, magnified productivity, and multitasking.

Robots enhance CNC machine tending by automating repetitive tasks like loading, unloading, material handling, inspection, and other operations. This improves efficiency, reduces human error, and enables machines to run continuously, leading to increased productivity and consistency in operations.

cover plates for electrical box

disadvantages of cnc milling

craftsman 2000 series 5-drawer steel rolling tool cabinet red

disadvantages of cnc

Elitra 3 in 1 Under the Cabinet Electric Can Opener, Blade Sharpener, Bottle Opener, Under The Counter Mount, For Large And Small Cans, Black And Silver

benefits cnc machine tending|cnc machine pros and cons