dimension sheet metal drawing Dimension the part in a single direction wherever possible. Because of the sequential nature of the forming process, and the fact that dimensional variation is introduced at each bend, . Questions: But as a car turning from a minor road to a major road at an uncontrolled T-junction, when traffic is at a standstill before and after the yellow box, am I allowed to enter and stop in a yellow box?Highway Code Rule 174. Box junctions. These have criss-cross yellow lines painted on the road (see ‘Road markings‘). You MUST NOT enter the box until your exit road or lane is clear. However, you may enter the box and wait when .

0 · sheet metal layout drawings

1 · sheet metal drawing symbols

2 · sheet metal dimensioning standards

3 · sheet metal dimensioning guidelines

4 · sheet metal diagram fabrication

5 · sheet metal design basics

6 · sheet metal basic drawing

7 · sheet metal basic design guidelines

Check out our music box hong kong selection for the very best in unique or custom, handmade pieces from our music boxes shops.

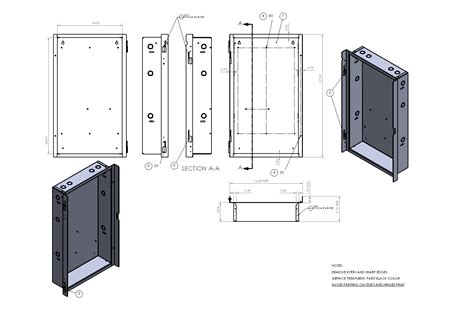

Reading a sheet metal drawing involves identifying the details of the design of sheet metal parts, such as dimensions, geometry, material specifications, and any special requirements. Meanwhile, detailing this .

Sheet metal drawings provide detailed dimensions, tolerances, and material requirements, helping manufacturers accurately understand design intent and produce products that meet specifications. Part sketches should be dimensioned and constrained in a manner that allows them to be easily modified without deforming the part and causing rebuild errors. Design intent .

Dimension the part in a single direction wherever possible. Because of the sequential nature of the forming process, and the fact that dimensional variation is introduced at each bend, .

This video demonstrates how to properly dimension a sheet metal layout technical drawing. It reviews general dimension standards as well as requirements for.Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost. Knowing how to dimension a part in a drawing makes metal fabricating that part much easier. Drafting, which you could call the “language of industry,” is not complete without dimensioning, writes Mark Schwendau. .In CAD drafting for sheet metal fabrication, dimensioning involves precisely annotating the size and location of features on 2D drawings or 3D models, crucial for part fit and function. This .

In this article, we’ll discuss how you can make sure you create technically correct and more manufacturable sheet metal drawings. The most important general considerations to make in design are precision in terms of .A fully dimensioned sheet metal drawing includes dimensions for all bends, holes, countersinks, flanges, and other formed features (such as hems and curls, ribs, dimples, etc.). It is a best practice to dimension to virtual intersection points and show included bend angles.

Reading a sheet metal drawing involves identifying the details of the design of sheet metal parts, such as dimensions, geometry, material specifications, and any special requirements. Meanwhile, detailing this information requires a series of .

sheet metal layout drawings

sheet metal drawing symbols

electric fence charger waterproof box

Sheet metal drawings provide detailed dimensions, tolerances, and material requirements, helping manufacturers accurately understand design intent and produce products that meet specifications. Part sketches should be dimensioned and constrained in a manner that allows them to be easily modified without deforming the part and causing rebuild errors. Design intent should be considered when creating part sketches.Dimension the part in a single direction wherever possible. Because of the sequential nature of the forming process, and the fact that dimensional variation is introduced at each bend, dimensioning in a single direction parallels the process and helps to .

This video demonstrates how to properly dimension a sheet metal layout technical drawing. It reviews general dimension standards as well as requirements for.Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost. Knowing how to dimension a part in a drawing makes metal fabricating that part much easier. Drafting, which you could call the “language of industry,” is not complete without dimensioning, writes Mark Schwendau. Getty Images. One of the most important aspects of drafting parts is dimensioning.

In CAD drafting for sheet metal fabrication, dimensioning involves precisely annotating the size and location of features on 2D drawings or 3D models, crucial for part fit and function. This includes In this article, we’ll discuss how you can make sure you create technically correct and more manufacturable sheet metal drawings. The most important general considerations to make in design are precision in terms of product design and the need to design for manufacturability.

A fully dimensioned sheet metal drawing includes dimensions for all bends, holes, countersinks, flanges, and other formed features (such as hems and curls, ribs, dimples, etc.). It is a best practice to dimension to virtual intersection points and show included bend angles.

Reading a sheet metal drawing involves identifying the details of the design of sheet metal parts, such as dimensions, geometry, material specifications, and any special requirements. Meanwhile, detailing this information requires a series of . Sheet metal drawings provide detailed dimensions, tolerances, and material requirements, helping manufacturers accurately understand design intent and produce products that meet specifications. Part sketches should be dimensioned and constrained in a manner that allows them to be easily modified without deforming the part and causing rebuild errors. Design intent should be considered when creating part sketches.

Dimension the part in a single direction wherever possible. Because of the sequential nature of the forming process, and the fact that dimensional variation is introduced at each bend, dimensioning in a single direction parallels the process and helps to . This video demonstrates how to properly dimension a sheet metal layout technical drawing. It reviews general dimension standards as well as requirements for.Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost. Knowing how to dimension a part in a drawing makes metal fabricating that part much easier. Drafting, which you could call the “language of industry,” is not complete without dimensioning, writes Mark Schwendau. Getty Images. One of the most important aspects of drafting parts is dimensioning.

In CAD drafting for sheet metal fabrication, dimensioning involves precisely annotating the size and location of features on 2D drawings or 3D models, crucial for part fit and function. This includes

electric fuse box for 2006 350 ford van

sheet metal dimensioning standards

We offer more than twelve thousands spare parts for you to choose. No matter you'd like to purchase new parts or relace the old with new, we'll send them to you as soon as possible to shorten the shut-down time.

dimension sheet metal drawing|sheet metal basic design guidelines