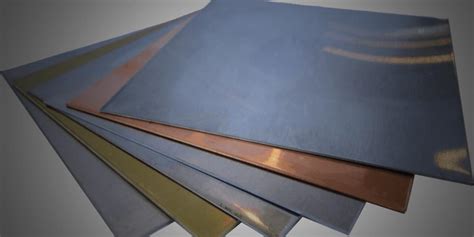

sheet metal 101 The forming of sheets of metal into components is a key manufacturing process for many industries. SOLIDWORKS includes tools for the creation, development, management, and documentation of Sheet Metal . Although sheet metal has its applications and knows for its unique qualities, there is no particular definition better than that. It’s instead called a processing technology that is the handbook or metal workers. What is Sheet Metal Used for? Types of Sheet Metal Explained. #1. Stainless steel sheets metals.

0 · what is sheet metal

1 · sheet metal manufacturing services

2 · sheet metal manufacturers near me

3 · sheet metal forming

4 · sheet metal formation

5 · sheet metal fabrication techniques

6 · sheet metal fabrication

7 · sheet metal cutting

This vintage bread box can hold two full loaves of bread with extra space to spare. Ideal for storing bread, pastries, donuts, cookies, and more, keeping it a long time and fresh. Metal Bread box with Bamboo Lid is a classic design to suit your vintage kitchen decor in white and black and highlight all your country kitchen accessories.

Learn the basics of sheet metal forming, including types of metal, techniques, tools, and challenges. EDCO Fabrication offers sheet metal services and advice for various industries. Sheet metal fabrication refers to the turning of flat metal sheets into metal products and structures. Typically, this technique involves transforming different types of sheet metals .

Sheet Metal Takeoff 101; MEP Books. EDITOR PICKS. Spiral vs Flexible Duct. August 14, 2023. HVAC Equipment Cost Database. May 10, 2021. Construction Job Walk Basics 101. January 2, 2021. ESTIMATING. HVAC School for . The forming of sheets of metal into components is a key manufacturing process for many industries. SOLIDWORKS includes tools for the creation, development, management, and documentation of Sheet Metal . Sheet metal fabrication is the process of transforming sheet metal (< 1/4” thick) into finished products, structures, and components. From household appliances to transportation, commercial equipment to construction, sheet metal fabrication is critical to modern manufacturing. In this article, we cover the basics of sheet metal fabrication, from material selection to key .

In this sector, sheet metal provides the foundation for durable, long-lasting structures that keep global transport systems running smoothly. Sheet Metal Fabrication: A Foundation for Innovation. Sheet metal fabrication plays a pivotal role in industries ranging from renewable energy to medical technology. The conditions and rules for press brake forming hems on sheet metal. Learn more at https://www.allmetalsfab.comHemming is a common sheet metal technique use.Business Profile for 101 Sheet Metal Inc. Sheet Metal Contractor. At-a-glance. Contact Information. 107 N Reino Rd #227. Newbury Park, CA 91320 (805) 499-7444. Customer Reviews. This business has .

Editor's Note: This series presents an overview of metal stamping. Part I focuses on the various careers in the metal stamping industry. Part II discusses stamping materials and equipment. Part III focuses on dies and cutting and Part IV offers more detail about cutting processes. Part V, the final installment, investigates forming methods.Welcome to Architectural Sheet Metal 101, your one-stop-shop for mastering the art of exterior sheet metal installation. With over 19 years of hands-on experience, we're here to guide you through .Sheet metal fabrication is a process of shaping and designing metal sheets in a cost-effective manner. Various techniques such as cutting, punching, bending, etc are used for the fabrication process which ensures production of robust fabricated materials with better metal finishes.. Today, all the major industries such as the automotive industry, aerospace industry, agricultural .

101 copper sheet/plate is used for electrical applications.101 Copper is commercially pure, at about 99.99% copper, and an oxygen-free alloy. This gives it excellent electrical and thermal conductivity and makes 101 copper plate immune to hydrogen embrittlement at .

what is sheet metal

Specialties: We specialize in commercial & light commercial HVAC (Heating, Ventilation, Air Conditioning) system installation and design. We have a complete duct fabrication shop. We have a service crew for repairs to any equipment we may install or for businesses that need HVAC repair and service. Established in 2002.Office Almirah (Sheet Metal) Model: ALO-0101. Size: L-912 X W-601 X H-1865MM. Color: SM Black. Spacifications: • Made from the World’s best Quality Mild Steel Sheet. • All surface of Mild Steel are mig welded, chemically de-rusted and zinc phosphate coated with oven backed heated powder paint finish that confirms anti rust, shiny color and longevity.Learn more about the sheet metal industry and the career opportunities it has to offer by taking a look at some of the incredible projects our space has work.Sheet Metal 101. Sheet metal fabrication involves converting metal parts into flat, narrow pieces. Once flat, the pieces are easily manipulated into different shapes. Professionals operate machines that can bend, slice, shrink, tuck, and stretch the metal. It is available in the following gauges: Foil (Less than 0.4 mm) Sheet metal (0.4 mm to 6 mm)

Additional Information for 101 Sheet Metal Inc. View full profile. Location of This Business 107 N Reino Rd #227, Newbury Park, CA 91320. BBB File Opened: 10/5/2022. Years in Business: 18. Sheet metal fabricators create durable and precise metal parts for various applications, from automotive to construction. It’s essential to understand the effects cutting and bending can have on raw sheet metal. Get started with our handy guide, “Sheet Metal Fabrication 101: What Is Bend Allowance?” Bend Allowance Explained

This item: Mitutoyo 118-101 Sheet Metal Micrometer, Ratchet Stop, 0-25mm Range, 0.01mm Graduation, +/-0.004mm Accuracy, 110mm Throat Depth . 3.00 $ 243. 00. Get it Feb 5 - 21. Usually ships within 5 to 6 days. .

Ryerson hosts interactive webinars Metal 101 (basics of metal) and Metal 102 (basics of fab) each year. Watch them on Ryerson's YouTube channel. . Metal Sheet. Metal 101. Explore the corrosion resistance of stainless steel and learn how it protects against rust and degradation. Discover why stainless steel is a top choice for durability in .Specialties: 34 years in the industry. custom mailboxes, gutters, Fascias, metal roofing. Builder Sheet Metal. if you can draw it, we can do it. Established in 2022. Eric started in the sheet metal trade in 1980's. Eric always knew he like's working out doors. 16 years with one company, and 18 years with another company. Now some 34 years later or more. Builder Sheet Metal is born.Sheet Metal Materials . Sheet metal fabrication utilizes a variety of metals, each with properties that make them suitable for different applications. The most common base metals used are: Steel – Steel is the most popular choice for sheet metal due to its high strength, formability, weldability, and relatively low cost. Common forms of steel .Sheet Metal Fabrication Surface Finishes Fabrication surface finishes to apply to sheet metal. Anodizing thickens the natural oxide layer on the metal, helping to give the component excellent corrosion and wear resistance properties.It improves the hardness and durability of the surface with a smooth, matte finish.

Sheet Metal Stamping 101 - Art Hedrick - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. A collection of Art Hedrick's web articles on Sheet Metal Stamping Gathered together in one document. Continuing his series about sheet metal stamping, tool-and-die expert Art Hedrick focuses on die basics, including die materials and rudimentary maintenance. He also explains the cutting process and what happens to metal when you cut it with a stamping die. . Sheet Metal Stamping 101, Part III Dies and cutting. By Art Hedrick; August 25, 2009 . 4 talking about this. Keeping the Architectural Sheet Metal trade alive through education and community Architectural Sheet Metal 101 Me doing some good ol’ deburring with a flat file. Another day, another workshop! Yesterday I headed over to the Sheet Metal 101 class with Louise, who’s obviously graduated from the beginner course, but wanted to get a better feel for how the regular sheet metal practical is presented as opposed to the women’s one we attended on Monday.

Editor's Note: This series presents an overview of metal stamping. Part I of this series focused on the various careers in the metal stamping industry. Part II discussed stamping materials and equipment; Part III focused on dies and cutting and Part IV offered more detail about cutting processes. The final installment, Part V, investigates forming methods.101 Sheet Metal Inc is a Specialty Contractor that serves the Newbury Park, CA area and specializes in Metal Wall Panels, Sheet Metal Roofing, Roof Panels, Sheet Metal Wall Cladding, Sheet Metal Flashing and Trim, Metal Faced Panels.

sheet metal manufacturing services

The ATEX directive uses zones to classify potentially explosive gas and dust atmospheres. Classifications range from an ignitable condition being an unlikely occurrence (Zones 2 and 22) to continuously present (Zones 0 and 20).

sheet metal 101|sheet metal manufacturing services