mig settings for sheet metal Now. let’s make some settings. For simplicity’s sake, I’m going to stick with settings for mild steel for the most part because it’s by far the most-welded metal on the planet. I’ll mention aluminum or other materials whenever they’re relevant. See more We fabricate and weld aluminum and stainless steel products, as well. With our mobile truck, equipped with power, water and a 4000 Ib crane, we have the knowledge and capability to do a large range of on site repairs and installations.

0 · miller welding mig settings

1 · mig welding sheet metal chart

2 · mig welding sheet metal

3 · mig welding settings

4 · mig welding parameters

5 · mig welding gas settings

6 · mig welder temperature settings

7 · mig welder settings pdf

Unsurprisingly, the most likely reason your water tastes metallic is because it. has metal in it! Specifically, deposits of iron, zinc, or manganese probably leached into your water. Metallic deposits usually leach into your water after it’s already been treated, so nothing stops these particles from reaching you.

There’s more to this than grabbing your MIG machine and twisting the dials. Your MIG settings, like those of any welding process, depend heavily on the job you’re approaching. There’s no generic assortment of settings that always applies. Welding is a custom craft, and it depends on a lot of variables. See more

Now. let’s make some settings. For simplicity’s sake, I’m going to stick with settings for mild steel for the most part because it’s by far the most-welded metal on the planet. I’ll mention aluminum or other materials whenever they’re relevant. See moreAnother way to check your MIG settings is to inspect the weld bead. It will tell you what it needs. You just have to pay attention. 1. Normal bead: Good penetration into the . See moreThere are many MIG setting charts available from manufacturers that all vary. Here’s a settings chart I put together that is a general guide to get you started – remember this is just . See moreIt may be a disappointment to some, finding out there’s no quick, easy answer to the questions you’re grappling with. When it comes to . See more

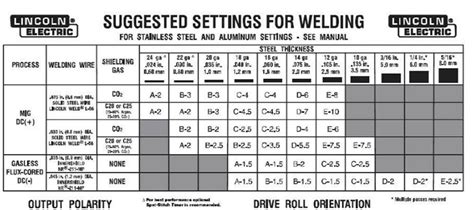

Find below the MIG Welding Sheet Metal Settings Chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. To ensure optimal results, select the appropriate gauge thickness . The following basic MIG welding settings are for welding steel with solid wire. Joint design, position and other factors affect results and settings. .

In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and we. This series includes MIG-230MINI, MIG-230, MIG-280, MIG-280PLUS, MIG-350, MIG-350W, MIG-500, and MIG-500W to fit all your demands of welding either on daily metal fabrication or heavy-industry application. The .

Auto body sheet metal is relatively thin, and this can present some challenges for welders particularly those who are accustomed to welding thicker materials. Welding nearly always causes some distortion: the metal in and .

Related Reading: mig welding sheet metal settings with Charts. For thin sheet metal welding it can be 30 ampere while for thicker (e.g. 1/8” square groove weld)- it can go up to 220 ampere for example. . Stick Welding Amperage for Thin Sheet Metal Welding. Use 50-ampere current when welding with E6013 diameter 5/64 inch. For smaller gauge .MIG welding is challenging, mainly when working with a thin metal sheet. We hope this guideline, including different tips on welding sheet metal with a MIG welder, helps you achieve the best results. Nonetheless, you must never forget that MIG . For sheet metal what is the welding current needed. i see some machines with low of 15 amp, 20 amp 30 amp. brokenbiker Member. Messages 10,436 . I have never successfully used less than 55 on its mig setting. Most of the time on thin sheet you will be doing stitch or joining up tacks.

Learn how to MIG weld automotive sheet metal in about 5 minutes or less! I keep it short and to the point in this welding instructional video and show how v.Settings for MIG welding sheet metal(14 gauge) steel? I have been messing around with settings and just want to get some extra input on what you guys do. Thanks! . I actually welded some iron boxes at work a few weeks back that was 11 or 12 to 14 gauge sheet metal. I wasn’t allowed much burn through on the back, just a light sugaring if I . Before setting up your MIG welder, you need to do some research and make a few preparations like finding out where you can get a MIG welder setting chart Trusted Source R-Tech MIG180 Mig Welder WELDING SETTINGS CARBON STEEL – 0.6MM WIRE DIAMETER www.r-techwelding.co.uk . You can get this information welding technician programs. MIG welding sheet metal can be hard, as there’s a lot of heat involved in the process. The trick is finding a balance between the heat and time spent on it. . Settings. When you’re working with sheet metal, the best thing you can do is get some extra metal that’s the same thickness and play around with the settings (and practice your .

You don't need TIG for sheet metal; you just need the right settings and a lesson—like all of us do. Most auto body shops don't use TIG for panels; they use MIG, and that says a lot. Your machine can work fine, with a few operator tricks. The biggest mistakes with sheet metal welding are gap and heat. Flux core is way harder to do on thin metal. Welding / Fabrication - welding sheet metal with Lincoln 140 - trying to fill the holes in the engine bay. my problem is that i am constantly burning through the material. its get to a point where it burns the hole bigger, so i hold onto the trigger and circle over it several time till there is a mountain of weld over.This video is a tutorial on welding thin metal with the UNIMIG VIPER 185Email: [email protected] That’s where your Lincoln 140 MIG welder settings chart comes in. And it’s not in the manual. You’ll find it on your welding decal. On the inside of your Lincoln 140’s cabinet door. . And you risk blowing straight through those thinner gauges of metal. The Lincoln 140 Setting Chart Green Column. When you look the middle. You’ll find .

MIG Welding Sheet Metal. Gas metal arc welding (GMAW or MIG) can be successfully used to weld thin metal, but as long as you take extra care. The heat input is the main issue with sheet metal of 24 gauge up to 14 ga. Thin metal is . Plug welding kits include pre-cut blanks in multiple sizes plus a step-style bit for drilling sheet metal. Sheet metal patch – If you lose control of the blow-through altogether, you may need to remove the damaged area entirely .

The best welders for sheet metal is a MIG or TIG welder due to their precision and control. Key specifications include a wide amperage range for better control, a high duty cycle for longer welding sessions, and a stable arc .But before using these values, we suggest that you have a decent understanding of your preferred metal. Also, consider the amperage settings and the task at hand. Lincoln MIG Welding Settings Chart for E71T-GS + Flux Core + Tubular electrodes. . Lincoln MIG Welding Settings Chart for ER70S-6 + 75% AR/25% CO2+20CFH ( 0.30 Wire Size) In this video I show how to set up your mig welder to be able to weld on super thin metal with out warping it. I go through step by step comparing how to pre. In this video I show you how to properly set up your welder settings for thin sheet metal welding on automotive car or trucks repairs for beginners.In this v.

Techniques for MIG welding thin sheet metal. MIG welding thin sheet metal requires specific techniques to ensure a successful weld. Here are some tips to help you achieve high-quality welds: Maintain a short arc length: Keep the arc length as short as possible without touching the metal. A shorter arc length helps to minimize heat input and .

miller welding mig settings

Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several . Settings and techniques. The MIG settings for galvanized steel are similar to regular steel, with some modifications to help burn the zinc. The following recommendations are quite useful, especially for the short-circuit mode: Always use a 20 or even 30% slower traveling speed to increase the heat input. This is an effective and easy way to .

MIG welding (Metal Inert Gas Welding) is an arc welding process that uses a continuous solid wire electrode and shielding gas to lay the weld. Another name for MIG welding is GMAW (Gas Metal Arc Welding). In some places, people also colloquially refer to it as “wire welding”. MIG welding is a common welding process that is widely used in manufacturing . It aids in the optimal setting of your MIG welder for effective, high-quality welds. Table of Contents . You’ll need lower wire speeds when welding thin materials like sheet metal. It prevents the risk of burn-through. . It calculates appropriate settings based on the type of metal, thickness, and wire type. Dive into the world of flux core welding with the Arccaptain MIG200! Our comprehensive guide unveils the secrets, techniques for mastering this challenging yet rewarding skill. From adjusting machine settings to addressing common challenges. Discover the finesse of flux core welding with our step-by-step walkthrough.

Mig and Flux Core - gas metal arc welding & flux cored arc welding . One trick with sheet metal (under 16 ga.) is to use a shielding gas with less CO2 and more argon. . with 0.6 mm wire and 0.6 mm base metal, is a 1/30 (Volts/Feed) settings. Alexa. Top. Otto Nobedder; Weldmonger; Posts: 8429. Joined: Fri Jan 07, 2011 4:40 am. Location: Near .

waterproof electrical connection box

Walters Sheet Metal, in Leesville, Louisiana, services and repairs various .

mig settings for sheet metal|mig welding settings