electrical control box wiring Wiring industrial control panels is a complex process and it needs a number of carefully planned and performed details. However, there are dozen of tips and advices on how to do this and that, but this technical article will limit to .

Most general aviation aircraft are designed to a load factor of between four and six. The various components that make up the wing structure must be capable of supporting this aerodynamic load throughout the certified design envelope.

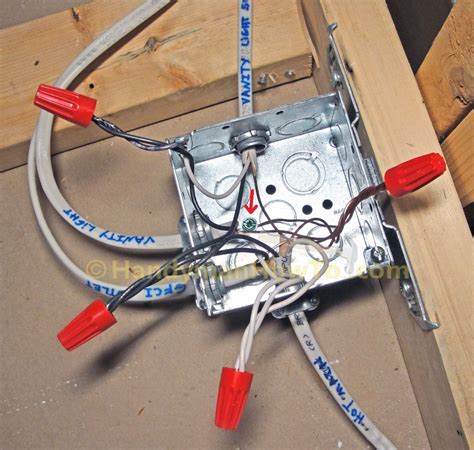

0 · wire connections in electrical box

1 · residential electrical junction box

2 · residential electric box

3 · home depot electrical outlet box

4 · exposed electrical outlet box

5 · electrical wire for outlet

6 · electrical outlet box installation

7 · electrical junction box with outlet

Find White Exterior electrical boxes at Lowe's today. Shop electrical boxes and a variety of electrical products online at Lowes.com.

A control system of a PLC panel will normally use AC and DC power at different voltage levels. Control cabinets are often supplied with single phase AC at 220/440/550V, or . Wires and preparation for control wiring. Electrical equipment uses a wide variety of wire and cable types and it is up to us to be able to correctly .The quality of the wiring methods used in an industrial control panel can vary quite widely. This article summarizes what this author believes are some best practice when it comes to control .Learn about PLC control panel wiring, including how to properly wire and connect components, as well as common troubleshooting tips. Discover the benefits of using a PLC control panel in industrial applications and understand the basics .

Understanding the wiring diagram of a panel box is crucial for electricians, homeowners, and anyone involved in the maintenance and repair of electrical systems. A panel box wiring diagram is a visual representation that shows the .

Wiring industrial control panels is a complex process and it needs a number of carefully planned and performed details. However, there are dozen of tips and advices on how to do this and that, but this technical article will limit to .

We will take you through the essential steps needed to build and assemble an electrical control panel to control your manufacturing process and ensure that it is safe and runs smoothly. .

We get many questions about the basics of electrical control panels, such as what devices and equipment we typically use, how the devices are wired, how to keep the control panel and the cabinet within a normal temperature range and so on. Control Panel Wiring Design Tips for Meeting NFPA Standards. Cable and wire are an underappreciated step in executing a great industrial control panel design. To help your final product run safely and smoothly, follow best practices for: Size; Wire type; Space; Routing; Safety circuits; Termination; Grounding; Labeling; 1. Size Wire Gauge. NFPA .

Many different techniques exist for connecting electrical conductors together: twisting, soldering, crimping (using compression connectors), and clamping (either by the tension of a spring or under the compression of a screw) are popular examples. A control system of a PLC panel will normally use AC and DC power at different voltage levels. Control cabinets are often supplied with single phase AC at 220/440/550V, or two phase AC at 220/440V AC, or three phase AC at 330/550V.

Wires and preparation for control wiring. Electrical equipment uses a wide variety of wire and cable types and it is up to us to be able to correctly identify and use the wires which have been specified. The wrong wire types will cause operational problems and .

The quality of the wiring methods used in an industrial control panel can vary quite widely. This article summarizes what this author believes are some best practice when it comes to control panel layout and wiring.Learn about PLC control panel wiring, including how to properly wire and connect components, as well as common troubleshooting tips. Discover the benefits of using a PLC control panel in industrial applications and understand the basics of wiring diagrams and panel layouts.Understanding the wiring diagram of a panel box is crucial for electricians, homeowners, and anyone involved in the maintenance and repair of electrical systems. A panel box wiring diagram is a visual representation that shows the various connections and components within a panel box.

Wiring industrial control panels is a complex process and it needs a number of carefully planned and performed details. However, there are dozen of tips and advices on how to do this and that, but this technical article will limit to .We will take you through the essential steps needed to build and assemble an electrical control panel to control your manufacturing process and ensure that it is safe and runs smoothly. Planning and Designing.We get many questions about the basics of electrical control panels, such as what devices and equipment we typically use, how the devices are wired, how to keep the control panel and the cabinet within a normal temperature range and so on.

Control Panel Wiring Design Tips for Meeting NFPA Standards. Cable and wire are an underappreciated step in executing a great industrial control panel design. To help your final product run safely and smoothly, follow best practices for: Size; Wire type; Space; Routing; Safety circuits; Termination; Grounding; Labeling; 1. Size Wire Gauge. NFPA .Many different techniques exist for connecting electrical conductors together: twisting, soldering, crimping (using compression connectors), and clamping (either by the tension of a spring or under the compression of a screw) are popular examples. A control system of a PLC panel will normally use AC and DC power at different voltage levels. Control cabinets are often supplied with single phase AC at 220/440/550V, or two phase AC at 220/440V AC, or three phase AC at 330/550V. Wires and preparation for control wiring. Electrical equipment uses a wide variety of wire and cable types and it is up to us to be able to correctly identify and use the wires which have been specified. The wrong wire types will cause operational problems and .

The quality of the wiring methods used in an industrial control panel can vary quite widely. This article summarizes what this author believes are some best practice when it comes to control panel layout and wiring.Learn about PLC control panel wiring, including how to properly wire and connect components, as well as common troubleshooting tips. Discover the benefits of using a PLC control panel in industrial applications and understand the basics of wiring diagrams and panel layouts.Understanding the wiring diagram of a panel box is crucial for electricians, homeowners, and anyone involved in the maintenance and repair of electrical systems. A panel box wiring diagram is a visual representation that shows the various connections and components within a panel box. Wiring industrial control panels is a complex process and it needs a number of carefully planned and performed details. However, there are dozen of tips and advices on how to do this and that, but this technical article will limit to .

how to tie in a wire with a junction box

Plastic junction boxes are lightweight, affordable, and resistant to corrosion. They are suitable for dry environments. Metal junction boxes are more durable, they are fire resistant and are used for wet or high-temperature areas.

electrical control box wiring|electrical wire for outlet