angle sheet metal for box construction There are numerous types of edges, joints, seams, and notches used to join sheet-metal work. We will discuss those that are most often used. Edges are formed to enhance the appearance . For example, you could have, in the subpanel, a 50 amp breaker for the welder, a 40 amp breaker for the EV charging station (that's enough unless you get a Tesla), a 30 amp breaker for the RV and a 15 amp breaker for the compressor, all fed from a 50 amp circuit.

0 · welding sheet metal boxes

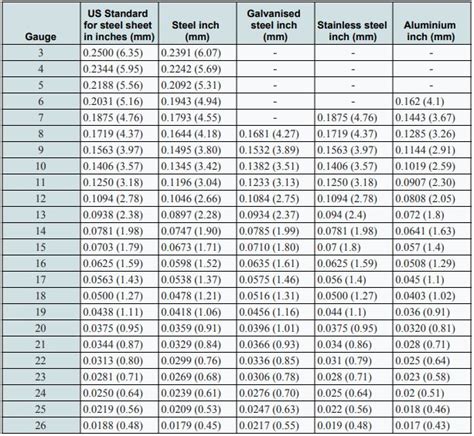

1 · sheet metal box size chart

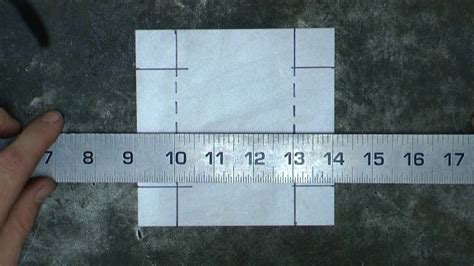

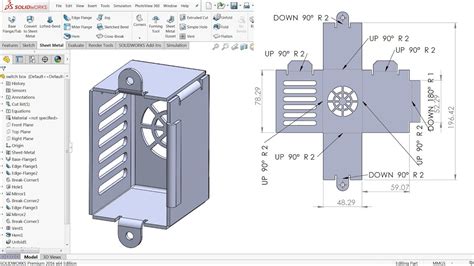

2 · sheet metal box layout

3 · sheet metal box instructions pdf

4 · sheet metal box dimensions

5 · sheet metal box design template

6 · how to fabricate sheet metal box

7 · how to bend sheet metal box

Best for Sourdough: Claimed Corner Metal Bread Box “The classic metal design saves kitchen space, air vents enough to keep the cake moist, and is suitable as a gift.” Best Wood: INDRESSME Bamboo 2- Layer Large Capacity Bread Box

Label all the areas on your metal that will be used for the box. Scratch 45 degree lines to angle off all of your hems and tabs.

A Riveted Metal Box With Lid: This is a practice box, so it's not very nice .A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal .There are numerous types of edges, joints, seams, and notches used to join sheet-metal work. We will discuss those that are most often used. Edges are formed to enhance the appearance . Use metal shears or a jigsaw to cut the sheet metal along the marked lines. Next, use a metal brake to bend the metal at 90-degree angles according to the box design. Apply a .

Sheet metal flanges offer strength, versatility, and ease of assembly. They improve the reliability and functionality of sheet metal components by providing structural support, sealing surfaces, . Choosing an iron angle for your project should consider material requirements, strength, shape, and thickness. See what to look for in selecting an iron angle.

Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to .Galvanized steel angles are ideal to use for building and construction projects. They are folded to a 90-degree angle with a wing on each side, making them suitable to use for reinforcing .

Corner construction plays a vital role in ensuring the durability and strength of sheet metal parts. When corners are not properly prepared for welding, it can lead to parts .

Designing a sheet metal box involves several considerations to ensure functionality, durability, and manufacturability. Key factors to consider include: 1. Material .Label all the areas on your metal that will be used for the box. Scratch 45 degree lines to angle off all of your hems and tabs.A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal shears, box brakes, pop-rivets, and so on.

There are numerous types of edges, joints, seams, and notches used to join sheet-metal work. We will discuss those that are most often used. Edges are formed to enhance the appearance of the work, to strengthen the piece, and to eliminate the cutting hazard of the raw edge. Use metal shears or a jigsaw to cut the sheet metal along the marked lines. Next, use a metal brake to bend the metal at 90-degree angles according to the box design. Apply a deburring tool to remove any sharp edges from the metal. Use a MIG welder to join the metal pieces together along the edges.Sheet metal flanges offer strength, versatility, and ease of assembly. They improve the reliability and functionality of sheet metal components by providing structural support, sealing surfaces, and mounting surfaces. Understanding when and how to utilize flanges can help manufacturers optimize their designs and performance. Choosing an iron angle for your project should consider material requirements, strength, shape, and thickness. See what to look for in selecting an iron angle.

Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape.Galvanized steel angles are ideal to use for building and construction projects. They are folded to a 90-degree angle with a wing on each side, making them suitable to use for reinforcing corners and edges. Corner construction plays a vital role in ensuring the durability and strength of sheet metal parts. When corners are not properly prepared for welding, it can lead to parts being out of tolerance, weak, and susceptible to breakage. Designing a sheet metal box involves several considerations to ensure functionality, durability, and manufacturability. Key factors to consider include: 1. Material Selection.

Label all the areas on your metal that will be used for the box. Scratch 45 degree lines to angle off all of your hems and tabs.A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal shears, box brakes, pop-rivets, and so on.

There are numerous types of edges, joints, seams, and notches used to join sheet-metal work. We will discuss those that are most often used. Edges are formed to enhance the appearance of the work, to strengthen the piece, and to eliminate the cutting hazard of the raw edge. Use metal shears or a jigsaw to cut the sheet metal along the marked lines. Next, use a metal brake to bend the metal at 90-degree angles according to the box design. Apply a deburring tool to remove any sharp edges from the metal. Use a MIG welder to join the metal pieces together along the edges.Sheet metal flanges offer strength, versatility, and ease of assembly. They improve the reliability and functionality of sheet metal components by providing structural support, sealing surfaces, and mounting surfaces. Understanding when and how to utilize flanges can help manufacturers optimize their designs and performance. Choosing an iron angle for your project should consider material requirements, strength, shape, and thickness. See what to look for in selecting an iron angle.

Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape.

welding sheet metal boxes

Galvanized steel angles are ideal to use for building and construction projects. They are folded to a 90-degree angle with a wing on each side, making them suitable to use for reinforcing corners and edges. Corner construction plays a vital role in ensuring the durability and strength of sheet metal parts. When corners are not properly prepared for welding, it can lead to parts being out of tolerance, weak, and susceptible to breakage.

okad-2417 single door stainless steel 304 cabinet door

A box junction is a road traffic control measure designed to prevent congestion and ensure the smooth flow of vehicles through busy intersections. It is characterised by a grid of criss-cross yellow lines painted on the road surface.

angle sheet metal for box construction|how to bend sheet metal box