cnc machine configuration Regardless of a particular original equipment manufacturer machine tool builder, there are several common configurations for 5-axis CNC machines that are available. Each one has its own set of strengths that make it stand out among . $578.00

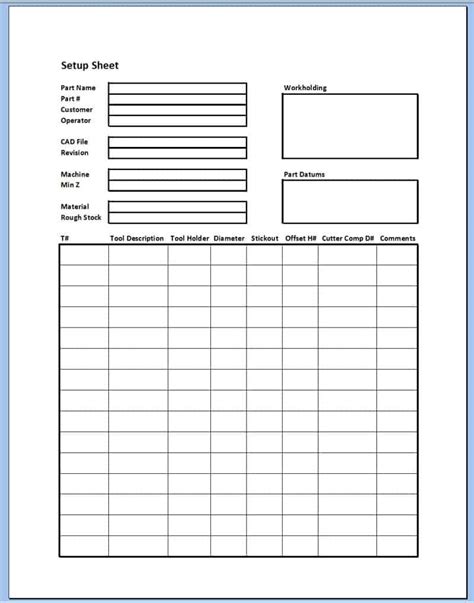

0 · cnc tool set up sheet

1 · cnc machines for dummies

2 · cnc machine setup sheet template

3 · cnc machine setup checklist

4 · cnc machine set up sheet

5 · cnc machine process step by

6 · cnc machine operating instructions

7 · cnc lathe setup sheet

Check out our vintage truck box selection for the very best in unique or custom, handmade pieces from our boxes & bins shops.

Regardless of a particular original equipment manufacturer machine tool builder, there are several common configurations for 5-axis CNC machines that are available. Each one has its own set of strengths that make it stand out among .Overview of the dedicated 5-axis machining configurations. Focusing on the Swivel head, trunnion table, and travelling column 5-axis CNC machines

Regardless of a particular original equipment manufacturer machine tool builder, there are several common configurations for 5-axis CNC machines that are available. Each one has its own set of strengths that make it stand out among the choices.Overview of the dedicated 5-axis machining configurations. Focusing on the Swivel head, trunnion table, and travelling column 5-axis CNC machines5-axis CNC machines come in various configurations, each with its own strengths and weaknesses. Let’s explore the main types: Table-table, Head-table, and Head-head configurations, focusing on the Trunnion and Swivel head designs, as well as the Traveling Column 5-Axis Machining Center. Companies that manufacture 5-axis CNC machines generally provide such customized solutions regarding 5-axis CNC machining. Configuration Types for 5-Axis Machining Center. Table-table, head-table, and head-head are examples of common 5 .

5 axis CNC machining uses a machine that can simultaneously move and rotate in five axes to machine a part. Its benefits include its high suitability for fabricating parts with complex designs and intricate details, accuracy, speed, and production efficiency.

What is CNC Machine Configuration? CNC machine configuration is the process of assembling and arranging various components and making arrangements for a Computer Numerical Control (CNC) machine to meet specific manufacturing requirements. At its core, 5-axis machining refers to the capability of a CNC machine to move a part or a tool on five different axes simultaneously. Traditional 3-axis machines operate on the X, Y, and Z axes, allowing movement in three primary directions: up and down, left and right, and forward and backward.

From 30-foot tables and four-foot Z-travel distances to rotating heads for 3D carving and special parts fixturing, CNT Motion Systems can help you determine a CNC machine configuration that’s perfect for your application.

What is a 5-axis CNC Machine? A 5-axis CNC Machine (also known as 5-axis Machining Center) is a precision CNC machine tool that uses a wide range of cutting tools to remove materials from a workpiece.

5-axis CNC machine, also known as 5-axis CNC machining center, comes in different configurations, but it usually consists of 3 axes: X, Y, Z, and two additional axes rotating around X and Y separately. 5-axis CNC is a kind of high-tech machine tool used for processing complex parts with high accuracy, often provides 5 axis machining parts for ae.Regardless of a particular original equipment manufacturer machine tool builder, there are several common configurations for 5-axis CNC machines that are available. Each one has its own set of strengths that make it stand out among the choices.

Overview of the dedicated 5-axis machining configurations. Focusing on the Swivel head, trunnion table, and travelling column 5-axis CNC machines5-axis CNC machines come in various configurations, each with its own strengths and weaknesses. Let’s explore the main types: Table-table, Head-table, and Head-head configurations, focusing on the Trunnion and Swivel head designs, as well as the Traveling Column 5-Axis Machining Center.

Companies that manufacture 5-axis CNC machines generally provide such customized solutions regarding 5-axis CNC machining. Configuration Types for 5-Axis Machining Center. Table-table, head-table, and head-head are examples of common 5 . 5 axis CNC machining uses a machine that can simultaneously move and rotate in five axes to machine a part. Its benefits include its high suitability for fabricating parts with complex designs and intricate details, accuracy, speed, and production efficiency.

What is CNC Machine Configuration? CNC machine configuration is the process of assembling and arranging various components and making arrangements for a Computer Numerical Control (CNC) machine to meet specific manufacturing requirements. At its core, 5-axis machining refers to the capability of a CNC machine to move a part or a tool on five different axes simultaneously. Traditional 3-axis machines operate on the X, Y, and Z axes, allowing movement in three primary directions: up and down, left and right, and forward and backward.From 30-foot tables and four-foot Z-travel distances to rotating heads for 3D carving and special parts fixturing, CNT Motion Systems can help you determine a CNC machine configuration that’s perfect for your application.

What is a 5-axis CNC Machine? A 5-axis CNC Machine (also known as 5-axis Machining Center) is a precision CNC machine tool that uses a wide range of cutting tools to remove materials from a workpiece.

cnc tool set up sheet

cnc machines for dummies

$95.00

cnc machine configuration|cnc lathe setup sheet