steel and concrete box girder To meet this requirement, the project engineers selected steel box girders and optimized the span layout, including using some of the largest steel girder segments ever to be transported and . This guide will provide an in-depth look at the types, manufacturing processes, benefits, applications, and future trends of stainless steel sheet products, giving you a thorough understanding of this high-performance material.

0 · tubular design vs girder

1 · steel box girder design example

2 · steel box girder design

3 · single cell box girder

4 · prestressed concrete box girder

5 · prestressed box girder

6 · maximum length of steel girder

7 · designing a steel girder beam

Here’s a breakdown of the most common types of electrical boxes you’ll encounter. 1. Standard Rectangular Boxes. These are the most commonly used electrical boxes, typically used for light switches and outlets. Made of either metal or plastic, these boxes are installed in walls, and they provide a secure housing for electrical connections.

The box girder normally comprises either prestressed concrete, structural steel, or a composite of steel and reinforced concrete. A box girder is formed when two web plates are joined by a common flange at both the top and the bottom.A box girder bridge, or box section bridge, is a bridge in which the main beams comprise girders in the shape of a hollow box. The box girder normally comprises prestressed concrete, structural steel, or a composite of steel and reinforced concrete. The box is typically rectangular or trapezoidal in cross-section. Box girder bridges are commonly used for highway flyovers and for modern elevate.

Composite box girder construction offers an attractive and economic form of construction for medium span highway bridges. The torsional properties of the closed section are often .

To meet this requirement, the project engineers selected steel box girders and optimized the span layout, including using some of the largest steel girder segments ever to be transported and .Steel box girders and steel and concrete composite box girders are used for long spans, where the self weight of the bridge needs to be minimized, and for situations where their excellent .

Precast, pretensioned concrete box girders (precast box girders) are typically used for relatively short span structures with limited or inadequate temporary clearance for a falsework, as . Prestressed concrete (PSC) box girders are considered one of the most flexible forms of the bridge deck. For spans above 50 meters, PSC Segmental Box Girder Bridges are the economical choice. The webinar .

tubular design vs girder

Box girder bridge's design offers high torsional stiffness and strength, making it ideal for long spans, curves, and complex alignments in modern infrastructure. A box girder bridge is a type of bridge where the .

In this study, experiments and theoretical analysis were conducted to characterize the longitudinal force transfer mechanisms of the steel-concrete combination segment in .Box girder bridges can be constructed in different ways according to their types. The general methods are cast in situ, fabrication and assembling, precast, and arrangement of smaller units. The concrete box girder bridge is generally cast .

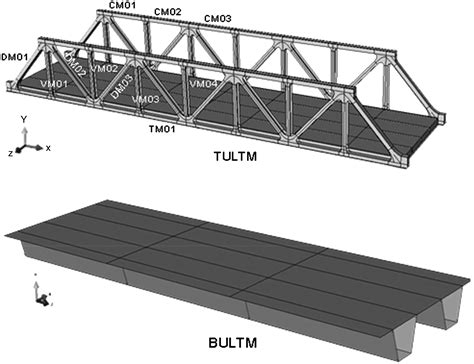

One of the early attempt advanced a new composite box girder bridge type [1, 2], which utilized corrugated steel webs (CSWs) to replace bulky concrete web, as shown in Fig. 1 (a). Compared to flat steel webs, the geometrical shape of CSWs enables the new box girder higher out-of-plane bending rigidity and trifling stiffness along the axial .

Steel-concrete composite box girder was used in long-span bridges for high-speed railways. The application of ballastless track on long-span bridges was a common trend in China, thus forming a new-type steel-concrete composite box girder-ballastless track system. A single arch-tower cable-stayed bridge located at 29.01°N,117.73°E was selected .

steel box girder design example

Some alternatives for the design of steel-concrete composite box girder bridges are presented in Figure 1 together with a detail of the steel-concrete interface, highlighting the position of the .

1. Introduction. A hybrid box girder cable-stayed bridge is a bridge structure that combines the use of both steel and concrete materials [].Steel box girders are utilized in the main span section to enhance the bridge span due to their lightweight nature, high strength, rapid construction, and ability to circumvent the drawbacks associated with concrete materials, such as self-weight, . Curved steel–concrete composite box girder bridges are gradually adopted in urban overpass and ramp curved bridges for its advantages of being light, rigid and straightforward to construct. When single-column piers are adopted as substructures, the lateral overturning stability of the girders must be validated.

The cross-section of the bridge adopts a single-box single-chamber combination cross-section, which consists of a concrete deck slab and a grooved steel box. The steel girder features a single-box, single-compartment channelized cross-section that is encompassed by the bottom plate, the top plate of the upper flange, and the web plate.steel rolled beams or plate girders and precast concrete box or beam superstructures with concrete decks. However, there is industry and owner confusion on how the different types of bridges compare on a Life Cycle Cost basis. Both the concrete industry and the steel industry site various anecdotal advantage above the other for

Steel box girders and steel and concrete composite box girders are used for long spans, where the self weight of the bridge needs to be minimized, and for situations where their excellent high torsional stiffness is of particular benefit. The clean lines of box girders bridges, usually with no visible external stiffening, is generally considered to give a excellent appearance and durability . In this research, a hybrid evaluation method of the SBNL was proposed to carry out a parametric study of steel and concrete box girders. First, the relationship between plate bending wavelength, critical frequency, and structural vibration radiation noise was theoretically discussed and derived for the SBNL of these two girders. A hammer test .

Stress (von Mises) distribution in steel box girder and concrete slab of Bridge type 8. Under load combination at Strength III Limit State considering wind loads, the relation between the LF and N for various span lengths is indicated in Fig. 15 (a)–(d). It can be seen that the LF changes slightly when N increases from 0 to 7 in all case studies. Post-fire assessment of composite steel-concrete box-girder bridges: Lessons from a recent incident. Author links open overlay panel Juan Jos . ensuring the effective collaboration of the concrete slab and steel girders as an integrated system. Consequently, the behaviour of the connectors was deemed non-critical for the overall structural . A Box girder bridge is a multi-span steel truss bridge/prestressed concrete characterized by a very large, hollow box-shaped steel beam that is used to span between two piers. The Box girder bridge design consists of three . The concrete box girder is one of the most commonly used structure forms for bridges because of its large flexural and torsional stiffnesses. However, with the increase of span length, the self-weight of a concrete box girder may increase rapidly, which restricts its use in long-span bridges [1].One of the most promising ways to reduce the self-weight of bridges is to .

steel box girder design

A steel–concrete composite box girder has good anti-seismic energy dissipation capacity, absorbs seismic energy, and reduces seismic action. It is very suitable for high-rise and super high-rise mega composite structure systems, which is in accordance with the condition of capital construction. In order to accurately study the elastic–plastic seismic response of the . In the case of steel-concrete composite box girders, the a reas of structural concrete are. transformed to steel on a modular basis. The Young modular ratio is used for flexion, and the.

The Yongjiang River Bridge on the North Ring Link of the Ningbo Railway Terminal is a steel and concrete hybrid box girder cable-stayed bridge of semi-floating structural system. The span . The present study is aimed to investigate the post-critical behavior of a side-box steel-concrete composite girder under varying wind angles of attack, by conducting a series of section model testing with single-degree and two-degrees of freedom. The essence of flutter, as well as the adverse impact of vortex shedding lock-in on exacerbating . A box girder concrete beam is a type of beam that is made up of a hollow box section. The box section is typically made of concrete, but it can also be made of steel or a composite material. The box section is designed to provide strength and rigidity, and the extended wings help distribute load. Concrete Box Girders are available a typical width of 12’ (3.66 m), . The joint section between steel and concrete box girders is the key localization of the super-long span hybrid girder cable-stayed bridge in the Edong Yangtze River, a high strength self .

Figure 5.4-2 Precast Box Girder Void Forms, Strand, and Reinforcing Steel (Courtesy of TYLin) For preliminary design, the girder type and associated depth can be taken from Table 5.4-1. This table is based on . 5.4.4 OVERLAYS AND CAST-IN-PLACE CONCRETE DECKS Precast box girders are cast on a flat surface. Transfer of the prestressingstrand to the The aim was to explore the application prospects of steel fiber-reinforced concrete in small box girders. The research results demonstrate that with increasing TNT equivalent, the leading cause of breach to concrete slabs changes from spalling to cratering. . To investigate the penetration of debris through the bottom plate of a concrete box .3 BEHAVIOUR OF BOX GIRDER BRIDGES 4 3.1 General 4 3.2 Bending, torsion and distortion 4 3.3 Torsion and torsional warping 6 3.4 Distortion 7 3.5 Stiffened compression flanges 11 3.6 Shear lag 11 3.7 Support of box girders 11 4 INITIAL DESIGN 13 4.1 General 13 4.2 Loadings 14 4.3 Choice of a box girder form 14 The boxes may be complete steel boxes with an overlay slab, or an open box where the concrete slab closes the top of the box. The use of the open steel box section allows the reintroduction of a bottom concrete compression flange at hogging moment regions by in-filling over supports giving a doubly composite section.

junction box installation standard

AbstractBecause a large longitudinal force exists in hybrid girder cable-stayed bridges due to the cable tension, its transfer mechanisms on the steel-concrete combination segment would be an important issue. In this study, experiments and theoretical analysis were conducted to characterize the longitudinal force transfer mechanisms of the steel-concrete combination . This paper collects the basic information of steel-concrete simply supported box girder bridges in China, analyzes And Summarizes its design parameters such as span, height-to-span ratio, bridge .

Precast Concrete Segmental Box-Girder Solution CTA’s original base design consisted of 60 ft steel spans supported by two drilled shafts at each concrete bent. The request for proposal for the project stated: The Contractor will not use through girders, steel box girders, trusses, tied arches, prestressed concrete beams, prestressed PDF | Steel-concrete composite girders have non-uniform stress distribution on the slab, presenting maximum stresses next to the webs of the girder.. | Find, read and cite all the research you .

junction box jb884

Following are the types of CNC machine: 1. CNC Lathe Machine. Lathe CNC machines are defined by their capability to turn materials during operation. They have less number of axes than CNC milling machines, making them shorter and more compact.

steel and concrete box girder|steel box girder design