stick welding sheet metal smaw thin steel How Do You Use a Stick Welder to Weld Thin Metal? The other name for the stick welding procedure is SMAW (Shielded Metal Arc Welding). This welding technique is older as compared to other types. However, it’s an . Haas has both Haas CNC Mill (VMCs) and horizontal machining centers (HMCs) .

0 · what is stick welding called

1 · types of stick welding

2 · stick welding for beginners

3 · stick welding explained

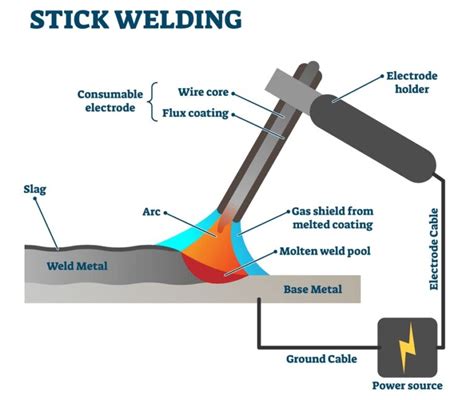

4 · stick welding diagram

5 · smaw equipment and setup information

6 · how does stick welding work

7 · beginners guide to stick welding

Get the best deals on CNC Machining Centers when you shop the largest online selection at eBay.com. Free shipping on many items | Browse your favorite brands | affordable prices.

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc . Stick Welding Thin Steel 04-18-2011, 08:16 AM. Many times, I have difficulty stick welding thin steel/sheet metal without burning a hole in it. . I use 6010/6011 for thin sheet metal. Heat and establish a puddle, move along your welding direction far enough to allow the puddle to freeze (keep moving. only pause at the puddle) and then move . How Do You Use a Stick Welder to Weld Thin Metal? The other name for the stick welding procedure is SMAW (Shielded Metal Arc Welding). This welding technique is older as compared to other types. However, it’s an . With the copper clamped to the back, you can weld the thin sheet steel like it is 1/4" thick bar. Use 1/8 inch, 7014, 7018, whatever, crank up the amps, 100 or more amps is OK,, When you weld, the excess heat will be .

I got some good practice today on repairing a mower handle frame - relatively thin wall tubing. My angle to it was to clean the breaks, bevel the edges, tack on one side, then bead on the other, cut the tack, and bead the originally tacked side. Rods were 5/64" 7014 for the beads, tacks were 1/8" 6010. Amperage on the 7014's I started out with was 40 amps.However, some practical advice might help you with higher gauge sheet metal. Stick Welding Equipment To Weld Thin Metal Like other welding methods, you won't need the most powerful Stick welder to weld thin sheet metal. Instead, you can do it with a YesWelder ARC-125DS DC Stick welder, rated at 20-125 amps with an easy arc start technology.

thin metal welding tricks that not all know. why didn't the welder tell this secretThis is a square tube welding technique, especially how to weld thin squar.

A fun challenge to test the limits of stick welding thin metal while providing 4 practical tips. Stick welding is great because of the simple equipment, port.Stick Welding Thin Metal. Stick welding is an industry's favorite welding method due to its low cost and high penetration and depositions. It allows you to complete the job quickly and cheaply, which is essential in large-scale applications, but the lack of heat control doesn't make it a favorable thin metal welding option. I have a DC converter max 200A made for stick only. (no sMAW or TIG). I train by myself watching videos on youtube and reading a lot. :) I only have 6013(I'm picky) and 7018(favorite) stick rods. I want to know if I can stick weld tin (or very thin steel sheet) , like the one in the image: Stick Welding Thin Metal. Welding thin metal is a challenging task, and it requires precision and care. Stick welding, also known as Shielded Metal Arc Welding (SMAW), is a versatile welding technique that can be used for welding thin metals. However, the heat output of stick welding is rarely lower than 20-30 amps, making it difficult to weld .

Smaller diameter welding rods are hard to run and not regularly used because stick welding produces a lot of heat and it’s easy to burn through thin metal. If you aren’t sure which type of electrode to buy then look at our comparison of 6010 vs 6011 vs 6013 vs 7018 vs 7024. How to choose welding rod amperage Any stick welding rod is going to have more arc force than 22 gauge can handle. By the time you get a nice arc established you already burned trough the metal. I also like the silicon bronze wire with 100% argon for 22 gauge steel. I can weld thin 22 gauge steel with .023" ER70S6 wire and 75/25 gas using my 120 volt Hobart MIG welder. how to weld thin metal correct??? this is the technique of welding thin square tubes with stickshow to weld thin metal correct??? this is the technique of . Stick welding different workpiece thicknesses can be tricky, especially if the welder is a relative newcomer to Shielded Metal Arc Welding (SMAW). It’s a technique that’s popular and fairly simple to master, that’s true enough, but it’s also a .

Stick welding, also known as shielded metal arc welding (SMAW), is a versatile and widely used welding process that involves the use of an electrode coated in flux to join metals. When it comes to sheet metal, the .

Those of you who have a stick welding (SMAW) machine may wonder whether you can . For example, if you’re welding ¼” thick metal, your electrode diameter should be less than ¼”. Example of a stainless steel . DCEP offers excellent penetration when stick welding. DCEN provides faster filler metal deposition rates when stick welding. But, since the penetration is reduced, DCEN is best used with thin sheet metal. DC .Harris mild steel alloys are perfect for welding cold rolled steel in thicknesses from thin sheet metal to thick plate steel. Conforming to AWS 5.18, these products are subjected to rigid quality control throughout the manufacturing process with particular attention given to cleanliness, cast and helix, resulting in a superior finished product. Tip-4: As you will be doing thin metal welding, the stick welder should not be overheated. Excessive heat will melt the metal. Tip-5: Since your metal is thin, keep your stick welding machine on a low setting. You can use small electrodes and the electrode moves fast.

While stick welding can be used with a lot of stuff it is not recommended to use it with thin sheet metals. It works best with thicker pieces of metal. You can use stick welding with everything ranging from stainless steel to cast iron, chrome, and nickel-based alloys. Aluminum might not be the best choice for stick welding, but it can be done.NOTICE - Each welding application is unique. Although certain Miller Electric products are designed to determine and default to certain typical welding parameters and settings based upon specific and relatively limited application variables input by the end user, such default settings are for reference purposes only; and final weld results can be affected by other variables and . The problem with stick welding is the thin stuff. 0.7mm is very thin. I'd say too thin for stick. 1.5mm sheet metal is okay but thinner than that and it's getting really, really tricky. To do 1mm you need to weld downhill, using backing plates or other tricks like that. Mig or tig is what you need for that. 3. Adjust Your Torch Angle. Changing the torch angle when MIG welding goes a long way to preventing burn-throughs. Make sure you adjust the angle to shorten the distance between the tip and the metal, no matter the welding position you work in.This will make the arc more stable, giving you more control over the weld and lessening the chance of burn-through.

How to weld thin gauge steel similar to car body panel, down to .8mm or 1/32 of an inch thick with arc or stick welder.DisclaimerDue to factors beyond the c. Stick welding, or shielded metal arc welding (SMAW), is a manual process that’s been used for decades and can be used on an array of metals, including stainless steel. Stick welding requires less equipment and training than other forms of welding, making it a great choice for those just starting out. In this guide, you will learn how to stick .

I have very limited experience stick welding anything thinner than 1/8" thick. I would like to use 20 or 22 gauge to keep the weight down; 18 gauge is an option if 20 or 22 is too thin. I don't see a backsplash needing a lot of structural strength. I can bend the backsplash in a sheet metal brake but the ends will be welded on.

While MIG and TIG welding is recommended for thin metal welding over stick welding, it is still possible to weld thin sheets of metal with this process. . One of the best electrodes to use for sheet metal is the 6013 rod. This is a fast-freeze rod that works well on thin gauge steel. The 6011 rods are also recommended for welding thin gauge .

white metal sheet

what is stick welding called

types of stick welding

Used Sheet Metal Box and Pan Brakes from National, Diacro, and more. Find suppliers near you at the world's leading directory for surplus machinery.

stick welding sheet metal smaw thin steel|types of stick welding