the ultimate guide to 4-axis cnc machines 5 axis CNC machining refers to a type of computer numerical control (CNC) machining that involves five different movements of the tool and workpiece. Unlike traditional 3-axis machines, which move . $52.94

0 · hobby 4 axis cnc machine

1 · cnc machine axis identification

2 · cnc 4th axis rotary

3 · 4d cnc machine

4 · 4 axis hobby cnc

5 · 4 axis cnc milling machine

6 · 4 axis cnc mill

7 · 4 axis cnc machine price

Junction boxes protect electrical wires from damage, prevent shocks, and stop sparks from igniting flammable material nearby. To install one, you’ll need to strip the ends off all the wires that will be in the box. To complete the electrical circuit, tie together the same-colored wires and hold them in place with wire nuts.

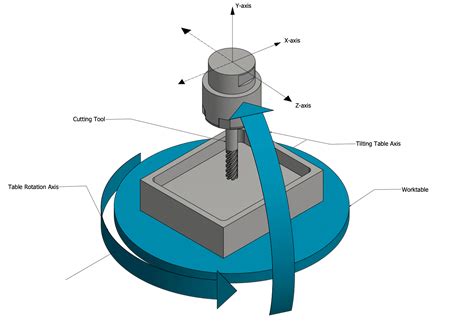

In this chapter, we'll start with the basics, explaining what a 4-axis CNC machine is and how it differs from other CNC machines. We'll explore the different axis configurations and how each . If you're looking to take your machining game to the next level, a 4-Axis CNC machine is the way to go. These powerful machines offer increased precision and versatility, .

The automation and precision of CNC machines reduce material waste, lower labor costs, and minimize the need for reworks or repairs. Applications of CNC Machines. CNC machines are utilized across a wide range of industries due to their versatility and efficiency. Here are some notable applications: Manufacturing 5 axis CNC machining refers to a type of computer numerical control (CNC) machining that involves five different movements of the tool and workpiece. Unlike traditional 3-axis machines, which move .The primary difference between 3 axis and 4 axis CNC machining is the addition of a rotational axis (A-axis) in 4 axis machining. This allows the workpiece to be rotated and machined from different angles, enabling more complex shapes and designs to be produced in a single setup.

Classical Machine; High-speed Machine; 4 Axis Machine; CNC Profiling Machine; 5 AXIS BRIDGE CUTTING MACHINE. 500 Series Bridge Saw; 700 Series Bridge Saw; 7 Axis Robot; . The Ultimate Guide to CNC Engraving Machines: Everything You Need to Know 2024-05-07. Share Share Link. Close share Copy link . CNC Machines and Their Axes 2-Axis and 3-Axis Machines. 3-axis CNC machines are the most common of the CNC machines. The 3 axes refer to linear motion in the X, Y, and Z axes. In milling, the tool spins to do the cutting. CNC lathes often only have two main axes of movement, with the stationary tool moving linearly in X and Y while the .

5-Axis Milling Machines . 5-axis milling machines are the most advanced type of CNC milling machine. They're capable of creating complex shapes and features that other machines can't handle. 5-axis milling machines are often used in aerospace, automotive, and medical manufacturing. Choosing the Right CNC Milling Machine for Your Needs

The rapidly changing world of manufacturing today necessitates the ability to apply such progressive machining technologies where necessary. This guide presents general information about CNC 5-axis milling, which is widely used as a high-tech method for machining complex shapes.It doesn’t matter whether you’re an expert machinist or just starting in the field. What is a 5 axis cnc machine?. A 5 axis CNC machine is a powerful tool used in the manufacturing industry to produce intricate and complex parts with precision. Unlike traditional CNC machines that operate in three axes (X, Y, and Z), 5 axis CNC machines offer two additional rotational axes (A and B) that allow for more flexibility and versatility in machining operations. The Ultimate Guide to 4 Axis Eight-head Stone Engraving Machine. Introduction to 4 Axis Eight-head Stone Engraving Machine. What is a 4 Axis Eight-head Stone Engraving Machine?. A 4 Axis Eight-head Stone Engraving Machine is a cutting-edge piece of technology that is revolutionizing the stone engraving industry. It is designed to provide precision and .

The Ultimate Guide to the FoxAlien Masuter 4040 CNC Router Machine. . CNC Machining. Equipped with 3-4-5 axis CNC milling and CNC turning machines, which enable us to handle even more complex parts with high precision. Rapid Injection molding. Low investment, fast lead time, perfect for your start-up business. .

Unlike 3-axis or 4-axis machines that are limited to linear and rotary movements, 5-axis machines offer added flexibility, allowing for complex cutting, shaping, and drilling operations. 2. Key Factors Influencing 5-Axis CNC Machine Prices:\ a. Machine Size and Configuration: The size and configuration of a 5-axis CNC machine greatly impact its . What is a 4 Axis Router? A 4 axis router is a versatile woodworking tool that allows you to cut intricately shaped patterns, grooves, and holes in wood. Unlike a traditional 3 axis router, a 4 axis router enables you to make cuts in multiple directions, adding a whole new dimension to your woodworking projects. This additional axis of movement . A CNC cutting machine, also known as a CNC cutter or CNC router, is a computer-controlled cutting device that uses specialized software to interpret design files and guide the cutting tools. These machines are equipped with a cutting head that can move along multiple axes, allowing them to cut precise shapes and patterns into various materials . 2-Axis Machine. 2-axis CNC machines or 2-axis milling machines, are types of computer numerical control (CNC) machines that operate along two axes. Through these, we usually plot the X-axis and the Y-axis. Benefits. Simplicity and Ease of Use: The first variations within this area are the two-axis CNC machines. They stand out and are simplistic .

What is a 5 axis cnc machine?. A 5 axis CNC machine is a powerful tool used in the manufacturing industry to produce intricate and complex parts with precision. Unlike traditional CNC machines that operate in three .

A 3-axis CNC (Computer Numerical Control) machine operates by moving a cutting tool or workpiece along three primary axes: X, Y, and Z. The X-axis controls the horizontal movement left to right, the Y-axis manages the horizontal movement front to back, and the Z-axis handles the vertical movement up and down. Introduction. compact cnc machines have revolutionized the manufacturing industry, allowing businesses of all sizes to benefit from the precision and efficiency that these machines offer.Whether you are a small workshop owner or a large-scale manufacturer, understanding the capabilities and advantages of compact CNC machines is crucial in today's .Limitations of 5-Axis CNC Machines . Types of 5-Axis CNC Machines for Desktop Use . Chapter 2: Key Features of 5-Axis CNC Machines . Precision and Accuracy Levels . Simultaneous Control of Multiple Axes . Tooling Options for Versatility . Compatibility with Various Materials . Modular Design for Flexibility and Scalability . Chapter 3 .

This article contains everything you need to know about CNC machining steel and various considerations for getting the best results. Steel is one of the most . The Ultimate Guide to 3, 4, and 5 Axis CNC Machining September 7, 2023 . The Ultimate Guide to CNC Machining Tolerances September 5, 2023 .

The automation and precision of CNC machines reduce material waste, lower labor costs, and minimize the need for reworks or repairs. Applications of CNC Machines. CNC machines are utilized across a wide range of industries due to their versatility and efficiency. Here are some notable applications: Manufacturing

Classical Machine; High-speed Machine; 4 Axis Machine; CNC Profiling Machine; 5 AXIS BRIDGE CUTTING MACHINE. 500 Series Bridge Saw; 700 Series Bridge Saw; 7 Axis Robot; SERVICE NEWS & BLOG . Welcome to the ultimate guide to at home cnc machines. In this article, we will explore the world of CNC machines that can be used in the comfort of your .2. Factors Influencing 6-Axis CNC Machine Prices . The cost of a 6-axis CNC machine is influenced by various factors that determine its value and functionalities. In this section, we will discuss these factors in detail, including machine size, type, brand, configuration, additional features, and the level of automation. Over the years, advancements in computer technology and automation have revolutionized CNC machines, making them an integral part of modern manufacturing processes. The Different Types of CNC Machines. CNC machines come in various types, each designed for specific applications. Some common types of CNC machines include: 1.

Educate readers on how to read and interpret a CNC machine electrical wiring diagram. Explain the symbols, notations, and color coding commonly used in wiring diagrams. Break down the different sections of the diagram. Section 4: Step-by-Step Guide to Wiring a CNC Machine\ Provide a detailed, step-by-step guide on wiring a CNC machine. The machine interprets the instructions and executes the desired tasks with utmost accuracy. The key components of an industrial CNC machine include the control panel, servo motors, spindle, tool changer, and the worktable. Applications of Industrial CNC Machines. Industrial CNC machines find wide-ranging applications across various industries.This guide has provided comprehensive insights into CNC machine tool repair, equipping readers with the knowledge and resources needed to keep their CNC machines running smoothly. Whether it's troubleshooting techniques or preventive maintenance tasks, embracing these best practices will lead to a more efficient and profitable CNC machining .

Over the years, advancements in computer technology and automation have revolutionized CNC machines, making them an integral part of modern manufacturing processes. The Different Types of CNC Machines. CNC machines come in various types, each designed for specific applications. Some common types of CNC machines include: 1.

hobby 4 axis cnc machine

electrical contractor box

electrical cose maximum junction boxes circuit

If there were more than one box to be connected, the EGC was spliced behind the box and extended over, so only one pipe clamp was used. Bare Buchannan splice caps were the device used to splice the pigtails.

the ultimate guide to 4-axis cnc machines|4 axis cnc milling machine