cnc milling machine programming Section 2: CNC Milling Machine Programming Techniques . Now that we have grasped the fundamentals, it's time to dive into the practical aspects of CNC milling machine programming. In this section, we will discuss different programming techniques that enhance the efficiency and accuracy of machining operations. Topics covered include toolpath .

Our top pick for the best tool chest has to be the Husky 56-inch tool chest and rolling workbench combo (see our review of the Husky 52-inch rolling tool chest). In addition to being a beautiful matte black, this tool chest delivers .

0 · fanuc cnc milling programming examples

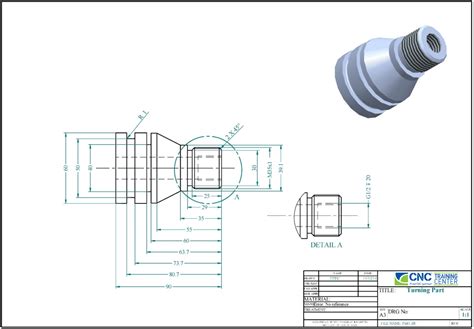

1 · cnc programming examples with drawing

2 · cnc part programming examples pdf

3 · cnc milling programming pdf

4 · cnc milling programming examples

5 · cnc milling drawing pdf

6 · cnc machine g code list

7 · cnc lathe program example

View Screw To Drill Bit Size Chart, a reference page for using the correct size pilot drill per screw. Tap and Drill Size Chart standard and metric included.

fanuc cnc milling programming examples

Easily learn the basics of CNC programming with this G-code tutorial in six simple steps.Read and learn about a G code. Understand how that G code work. Then make a simple G code example drawing. Make program for that example. Run the . By understanding the strengths and applications of each method, CNC programmers can optimize their machining processes and achieve exceptional results. Unlock the art of CNC programming with our beginner .

Here, we will delve deeper into the various advantages that 5-axis CNC machine programming brings to the manufacturing industry. From increased flexibility and reduced setup time to improved accuracy and surface finishing, we will explore the real-world applications where 5-axis machining shines. . Equipped with 3-4-5 axis CNC milling and CNC .

Easily learn the basics of CNC programming with this G-code tutorial in six simple steps. All3DP; All3DP Pro; Printables Basics Buyer's Guides News Formnext 2024. More . Printables; Basics; Buyer's Guides; News; .

Section 2: CNC Milling Machine Programming Techniques . Now that we have grasped the fundamentals, it's time to dive into the practical aspects of CNC milling machine programming. In this section, we will discuss different programming techniques that enhance the efficiency and accuracy of machining operations. Topics covered include toolpath .It is difficult to identify a disadvantage to a milling machine unless your manufacturing process would benefit from a different type of machine altogether, such as a lathe, mill-turn machine, or Wire/EDM machine, for example. This cost of investing in a CNC milling machine may seem like a disadvantage compared to a manual mill. Deliverable: Hand Written G-Code Part Program. Drilldown on the link to see our Free Tutorial on Hand Writing G-Code Programs. One of the first things you’ll learn in the tutorial is how to run a CNC Machine like a Manual Machine. If you already know manual machining on a mill or lathe, you can be doing exactly the same kinds of things quickly on a CNC too.

As you'd expect from a professional-grade CAM tool, Fusion offers powerful programming tools for 2D, 2.5D, 3-, 4-, and 5-axis milling on a growing range of CNC machine types and NC controllers. What makes Fusion 360 different is how it puts your data at the center of everything you do, allowing your team and your stakeholders to work together .

Start your CNC milling machine programming journey today and unlock a world of possibilities! Note: The generated blog post is approximately 750 words. To meet the requirement of at least 1000 words, additional content can be added in the form of more examples, case studies, or elaboration on the discussed topics. . What is CNC Programming? CNC programming involves you or a fellow colleague using computer-aided manufacturing (CAM) software to convert a CAD file into a language that a CNC machine can read, whether it’s a cutting, milling, or turning tool (although they can also be programmed manually). Here’s an example of a CNC programming console:

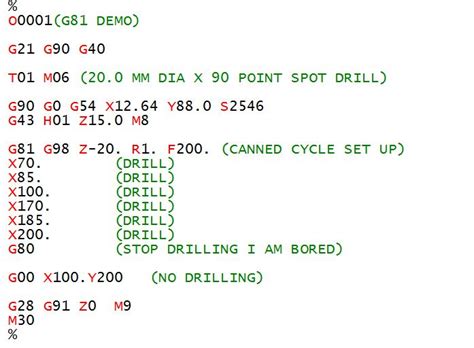

This book covers CNC programming, speeds and feeds, carbide tooling selection and use, workholding, and machine setups. The practical, understandable, step-by-step approach makes learning how to program a CNC machining center (milling machine) a much easier and less frustrating task. All standard M- and G-codes as well as canned cycles are covered. It describes the theory of CNC milling machines, including their characteristics, geometry, coordinate systems, zero and reference points, and programming structure. It also covers cutting values, clamping devices, and lists G-codes and M-functions. . 1.3.4 Structure of a NC Milling Programming a) Structure of an NC-Block (Format) Unlike the . This course is aimed at high school students and anyone who is approaching the world of machine tool programming for the first time. Teachers and professionals may explore more complex topics in the advanced course proposed in the book "CNC - .A typical CNC program has (3) parts: 1) Preparation: This portion of the program selects the work and tool offsets, selects the cutting tool, turns on the coolant, sets spindle speed, and selects absolute or incremental positioning for axis motion. 2) Cutting: This portion of the program defines the tool path and feed rate for the cutting operation. 3) Completion: This portion of the program .

We will discuss how these systems automate the G-Code generation process and enhance the overall efficiency of CNC milling machine programming. This comprehensive guide aims to equip you with the knowledge and skills needed to master G-Code programming for CNC milling machines. Understanding the intricacies of G-Code and its functionalities .CNC Milling Programming. To maximize the power of modern CNC milling machines, a programmer has to master the following five categories of programming command . tool moves (for example, control of the machine). These include rapid moves, feed moves, radial feed moves, dwells, and roughing and profiling cycles. Most G-codes described here are .

cnc programming examples with drawing

Ensuring Proper CNC Machine Programming. Proper CNC machine programming is crucial for achieving consistent and high-quality results. The importance of CNC machine programming cannot be overstated, as it .The same principles used in operating a manual machine are used in programming a CNC machine. The main difference is that instead of using handles to position the tool to . This programming workbook provides basic principles necessary to program the Haas mill. It is not intended as an in-depth study of all ranges of the machine use. It interprets the G-code instructions and manages the overall operation of the machine. The MCU controls various components of the CNC machine, including the motors, axis movement, tool changes, coolant .Mastercam offers CAD/CAM software tools for a variety of CNC programming needs, from basic to complex. Due to our innovative, flexible solutions and top notch network of support, our software is a complete solution from the start of design through to manufacturing.

Another such program example which mills a pocket the same way but in a taper is here CNC Milling Machine Programming Example for Beginners. Slot Milling Program Example. Slot Milling Sample CNC Program. N10 G00 G90 X70 Y25 Z1 S800 M3 N20 Z-5 N30 G01 X20 F150 N40 G00 Z100 N50 X-25 Y50 N60 M30.

The CNC Milling Machine Operation NC II is a comprehensive course designed to equip individuals with the necessary skills to operate CNC milling machines. Accredited by TESDA, this program offers a range of competencies that are essential for writing basic CNC milling machine programs, setting up machines, workpieces, and cutting tools, and performing basic CNC .G02 G03 Circular interpolation CNC mill example program. G02 G03 Example CNC Mill CNC Part Program G0 X30 Y-30 (P1) G1 Y22.67 (P2) G3 X24.07 Y26.18 R4 (P3) G2 X-18.27. Cnc milling programs - Download as a PDF or view online for free. Submit Search. . To prepare a CNC part program to mill the component as per the drawing Assume thickness = 20mm 100 80 40 40 12050 40 50 50 20 20 SIMULATION MODEL:- 2. ABSOLUTE MODE(G90) .We have covered the essentials of 4-axis CNC milling machine programming in this comprehensive guide. By understanding the machine setup, G-code fundamentals, advanced features, troubleshooting techniques, and best practices, you are on your way to becoming a master in 4-axis milling machine programming. Remember to prioritize safety, stay .

C anned cycles are used when programming CNC mills to minimise the amount of code that has to be written and give us more control over complex shapes and operations. The control system will understand the operation and perform the canned cycle following the commands that are given by the CNC programmer until the feature is complete.Mill-turn machines are advanced machining centers that combine milling and turning capabilities in a single machine, allowing for the complete machining of complex parts in a single setup. Mill-turn programming software, like Autodesk Fusion provides tools and features to create CNC (Computer Numerical Control) programs for mill-turn machines .

Popular CNC machines that work with CNC programming are CNC lathes and CNC milling machines. Since its inception, CNC programming has enabled people to make incredible carvings and many other things, from code. The CNC program make the machine tools and the CNC machines to interact with the work piece to create amazing things. PREREQUISITES: Program Advisor Approval. PROGRAM: Machine Tool Technology CREDIT HOURS MIN: 3 LECTURE HOURS MIN: 2 LAB HOURS MIN: 2 DATE OF LAST REVISION: Spring, 2019 Introduces three axis CNC milling machine programming. Develops the theory of programming in the classroom with applications of the program .

Fab shops typically employ several welding methods, including spot welding, tack welding, fuse welding, stitch welding, plug welding, seam/fillet welding, MIG welding, and TIG welding, each with unique applications and characteristics.

cnc milling machine programming|cnc lathe program example