cnc milling machine introduction The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation . I was wondering what the standard electrical wall mounting box used for sockets in america was. I was also wondering what the specifications for these boxes were, as well as, the pitch and size of the screw screw needed for the for the mounting holes.

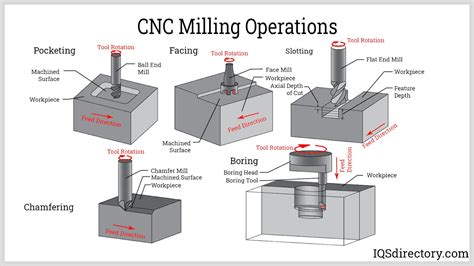

0 · types of cnc milling operations

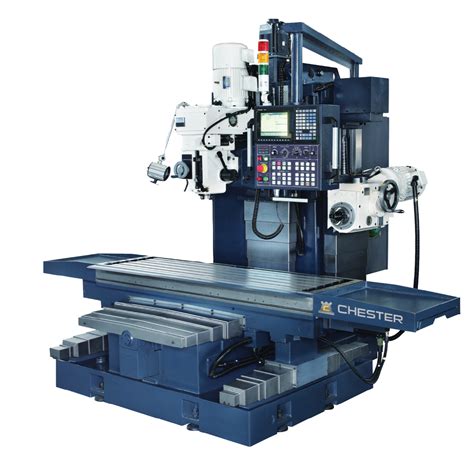

1 · type of cnc milling machine

2 · specifications of cnc milling machine

3 · milling process step by

4 · how cnc milling machine works

5 · cnc milling explained

6 · cnc horizontal milling for dummies

7 · basics of the cnc mill

$18.62

Dive into the introduction to CNC milling with this beginner's guide. Explore the basics, CNC milling processes, and insights to kickstart your CNC journey.

CNC Milling. CNC Milling. November 11, 2008. Curves on the CNC MIll. Remember the keyword MOVE is used to put the mill in s straight line mode. The keyword ARC is used to move the mill in an arc or circle. CIRCLE. Use .A 3-axis clone of a Bridgeport-style vertical milling machine. Milling is the process of machining using rotary cutters to remove material [1] by advancing a cutter into a workpiece.This may be done by varying directions [2] on one or several . The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation . Jiny Dental, also called Shanghai Jiny Electromechanical Technology Co., Ltd, was establised on 2013 in China, with years of experience in manufacturing the .

CNC Machining . Intro to CNC Machining • CNC stands for computer numeric controlled. It refers to any machine tool (i.e. mill, lathe, drill press, etc.) which uses a computer to electronically control the motion of one or more axes on the machine. • The development of NC machine tools started from a task supported

types of cnc milling operations

type of cnc milling machine

One of the most influential milestones in the history of CNC is the introduction of numerical control (NC) systems in the 1950s. . In conclusion, compact CNC milling machines and portable CNC technology are at the forefront of CNC miniaturization trends, offering significant advantages in terms of portability, adaptability, and customization . This document presents information about 5-axis CNC machines from several authors. It begins with an introduction to CNC machining and describes common CNC operations like milling and turning. The advantages of 5-axis CNC are discussed, including its ability to machine complex shapes in a single setup with improved accuracy.Introduction. When it comes to precision engineering and manufacturing, choosing between a manual milling machine and a CNC mill machine is crucial. . With CNC milling machines, operators can easily switch between different cutting tools and execute complex machining operations without manual intervention. This level of automation allows for . This post offers a brief introduction to CNC machining, or Computer Numerical Controlled machining. . has been around for centuries. Machining processes include: turning, drilling, milling, shaping, broaching and grinding. Next, "NC" stands for "Numerical Control." . many CNC machine shops make use of Distributed Numerical Control .

2. COMPUTER NUMERICAL CONTROL(CNC) INTRODUCTION Computer numerical control CNC) is one in which the functions and motions of a machine tool are controlled by means of a prepared program containing coded alphanumeric data. CNC can control the motion of the work piece or tool, the input parameters such as feed, depth of cut, speed, and . CNC Technology 01 - Introduction to CNC - CNC එකක් හදන එක දැන් ගොඩක් දෙනෙක්ගේ ආසාවක්. . Milling Machines; Turning Machines; Milling machines කියන්නේ වැඩ කොටස (Work piece) එක තැනකට හයි කරලා Cutting tool එකකින් . Definition of 5 Axis CNC Milling Machine. 5-axis machining is a type of CNC (computer numerical control) machining that manipulates tooling apparatuses in five directions or axes. This allows for more complex and precise machining, as the tool can approach the workpiece from multiple angles. How Does 5 Axis CNC Milling Machine Work?

The first CNC machine, a Cincinnati Hydrotel milling machine retrofitted with a computer control system, was introduced in the early 1960s. As computing technology advanced, CNC systems evolved from punch-card readers to more sophisticated computer interfaces.Introduction to Mini CNC Milling Machines. Mini CNC machines, or miniature milling machines, are compact versions of traditional CNC mills that offer the same level of precision and accuracy in a smaller footprint. These machines use computer-controlled movements to carve out intricate designs and shapes from various materials, making them .

specifications of cnc milling machine

3. Introduction of CNC Numerical control (NC) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium, as opposed to controlled manually. Most NC today is . Below, a CNC milling machine of welded construction is described, which is intended to be, at the same time, a test stand. . 1 Introduction . Aside fro m professional CNC machine tools used in .

Prior to the creation of CNC machines, drilling holes in material was done by: A. Large pack animals B. Handheld manual drilling braces with auger bits C. Scraping a sharp stone in a circular pattern D. Waterjets A pivotal milestone was reached in 1967 with the introduction of the first true CNC milling machine, which integrated computerized control for enhanced precision. Modern CNC gantry milling machines, such as the Mazak Variaxis and the Haas GR Series, feature bed, worktable, and CNC circuit control systems.Introduction to CNC Milling. Martin Brantner, Mechanical Engineering. Brandon Naylor, Energy Academic Group. Outline. Introduction. Workflow Process. CAD. CAM. Machining. . Keep in mind the CNC is a 3-axis machine. Goal is to export a .stl file. CAM (1/3) Determine single side, or double side machining.Introduction. CNC milling is a revolutionary technology that has transformed the manufacturing industry. This article will delve into CNC milling machines, their importance, and why understanding this process is beneficial. . CNC milling machines offer versatility in terms of material compatibility. They can easily handle various materials .

porta ferramentas torno cnc

6. • Base of both milling machines supports the entire machine. • Column also a structural member which houses the knee, spindle, bearing, gear box, clutches, shaft, pumps, power transmission mechanism for motor to spindle, etc. • Knee mounted in front of the column is for supporting the table and to provide an up or down motion along the Z axis.Study with Quizlet and memorize flashcards containing terms like What is a CNC milling machine with a tool changer and an enclosure called?, On a horizontal machining center, the X-axis corresponds to the _____., During the cutting action, the tool tip _____ the metal until the metal's fracture point is exceeded. and more.Milling machines can be manual machines, or they can be CNC (or computer numerically controlled). In some milling machines the spindle is oriented vertically. These machines are called vertical milling machines. The most common configuration of .Study with Quizlet and memorize flashcards containing terms like The part of a lathe that clamps the workpiece in place is called what?, During the cutting action, the tool tip _____ the metal until the metal's fracture point is exceeded., On a horizontal machining center, the X-axis corresponds to the _____. and more.

Introduction to my latest project: 3-Axis cnc milling machine. The frame and the mechanics of the machine are close to being finished. In the near future I'm. CNC machine is a machine tool that uses a high-speed rotating grinding wheel to remove metal from a workpiece. Learn its parts, working, types and advantages here . The different types of CNC Machines are: CNC Mills. Fig 3: CNC mill. CNC mills are machining centers equipped with computer controls to cut various materials. They interpret . 3. The first NC machines were built in the 1940s and 1950s by Prof. John T Parson. CNC machine came into existence after evolution of computer around 1980. Modern CNC Machine are improving further as the technology is changing with a variety of functions according to applications. In the early 1950s the Massachusetts Institute of Technology developed a .

milling process step by

Serve beer, kombucha, cold brew coffee, and wine with the American Beverage 4 Tap Jockey Box. This stainless steel cooler features 100' coils, shanks, and faucets, all built for premium beverage dispensing.

cnc milling machine introduction|specifications of cnc milling machine