cnc machine price per hour To calculate CNC machining cost per hour effectively, consider several key factors: . However, if you want to ensure that you have a truly cool roof with the most energy efficiency, its best to select the lightest roof color coatings, such as: white, bare metal colors, light blue, light green, beige, light grey, peach, etc.

0 · machinery cost per hour calculator

1 · machine cost per hour calculator

2 · how to calculate cnc cost

3 · cnc machine time cost

4 · cnc machine shop hourly rates

5 · cnc machine price calculator

6 · cnc machine hourly rate calculator

7 · cnc machine hourly rate

An electrical enclosure is a housing for electrical or electronic equipment. Its purpose is to protect that equipment from the environment (especially in the case of external electrical enclosures) and also to protect people from the equipment (e.g. to prevent electric shock or the propagation of an explosion).

The CNC machine hourly rate calculator helps shops estimate the costs of CNC machining jobs accurately. By considering various factors such as total cost of ownership, operator rate, working hours per day, downtime percentage, and markup, the calculator .

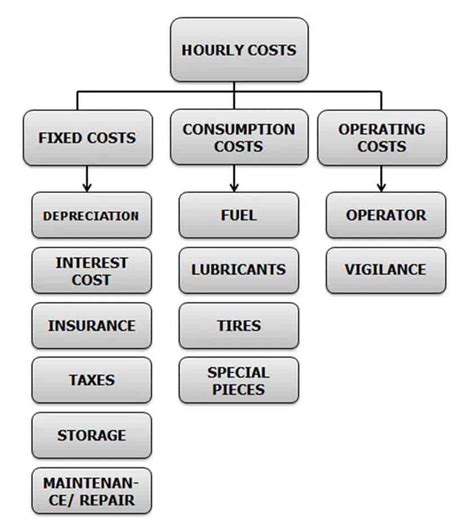

To calculate CNC machining cost per hour effectively, consider several key factors: . What you need to do is combine the Hourly Rate on a per machine basis with your estimate of how many hours will actually be needed from each . To calculate CNC machining cost per hour effectively, consider several key factors: machine depreciation, operator wages, overhead expenses, tooling costs, and material expenses. Start by determining the hourly rate of . Learn how CNC machining costs are calculated, including material types, batch sizes, machining time, and strategies to reduce expenses in your CNC projects.

Two factors influence machining expenses: the upfront cost of a CNC machine and its expected yearly usage, typically around 5000 hours. Machinists determine machine shop rates, commonly known as the machining . The size of the machine, typically measured as the cnc machine’s work envelope (X, Y, and Z coordinate range), is a huge determiner of machine cost. CNC Machines range from tiny in size (small enough to fit on a tabletop) .

The main factors contributing to the overall cost per hour of CNC operations include costs for labor, machine depreciation, material expenses, tooling, energy consumption, and overhead. This guide will help you learn . According to industry reports, brand new CNC routers can range from ,000 to 0,000 depending on their specifications. The market for used CNC machines shows a broad spectrum of pricing, where well-maintained .

Hourly rate + Material Cost = Price. An Example: /hr (2 Hours of Labor) + (Material Cost) = Price 5. Pricing your work doesn’t just set you apart from other brands; it also determines whether your business thrives or .

The CNC machine hourly rate calculator helps shops estimate the costs of CNC machining jobs accurately. By considering various factors such as total cost of ownership, operator rate, working hours per day, downtime percentage, and markup, the calculator provides a reliable hourly cost estimate. What you need to do is combine the Hourly Rate on a per machine basis with your estimate of how many hours will actually be needed from each machine. G-Wizard Estimator helps you build a simple spreadsheet to do this. A CNC machine can cost anywhere from a hundred couple of dollars to tens and even hundreds of thousands, depending on the type of CNC machine it is, the size and rigidity, the power and torque, number of axes, and many other factors.

To calculate CNC machining cost per hour effectively, consider several key factors: machine depreciation, operator wages, overhead expenses, tooling costs, and material expenses. Start by determining the hourly rate of your CNC machine, factoring in its purchase price, expected lifespan, and annual operating hours. Learn how CNC machining costs are calculated, including material types, batch sizes, machining time, and strategies to reduce expenses in your CNC projects. Two factors influence machining expenses: the upfront cost of a CNC machine and its expected yearly usage, typically around 5000 hours. Machinists determine machine shop rates, commonly known as the machining charge per hour, by dividing the price of CNC machines by their total yearly usage hours. The size of the machine, typically measured as the cnc machine’s work envelope (X, Y, and Z coordinate range), is a huge determiner of machine cost. CNC Machines range from tiny in size (small enough to fit on a tabletop) to gigantic (large enough you could drive a truck onto their work area).

The main factors contributing to the overall cost per hour of CNC operations include costs for labor, machine depreciation, material expenses, tooling, energy consumption, and overhead. This guide will help you learn about the cost calculation of CNC machining. What Determines CNC Machining Cost? According to industry reports, brand new CNC routers can range from ,000 to 0,000 depending on their specifications. The market for used CNC machines shows a broad spectrum of pricing, where well-maintained models can retain up to 70% of their original value. Hourly rate + Material Cost = Price. An Example: /hr (2 Hours of Labor) + (Material Cost) = Price 5. Pricing your work doesn’t just set you apart from other brands; it also determines whether your business thrives or fails, which is . The CNC machine hourly rate calculator helps shops estimate the costs of CNC machining jobs accurately. By considering various factors such as total cost of ownership, operator rate, working hours per day, downtime percentage, and markup, the calculator provides a reliable hourly cost estimate.

What you need to do is combine the Hourly Rate on a per machine basis with your estimate of how many hours will actually be needed from each machine. G-Wizard Estimator helps you build a simple spreadsheet to do this. A CNC machine can cost anywhere from a hundred couple of dollars to tens and even hundreds of thousands, depending on the type of CNC machine it is, the size and rigidity, the power and torque, number of axes, and many other factors.

To calculate CNC machining cost per hour effectively, consider several key factors: machine depreciation, operator wages, overhead expenses, tooling costs, and material expenses. Start by determining the hourly rate of your CNC machine, factoring in its purchase price, expected lifespan, and annual operating hours. Learn how CNC machining costs are calculated, including material types, batch sizes, machining time, and strategies to reduce expenses in your CNC projects. Two factors influence machining expenses: the upfront cost of a CNC machine and its expected yearly usage, typically around 5000 hours. Machinists determine machine shop rates, commonly known as the machining charge per hour, by dividing the price of CNC machines by their total yearly usage hours. The size of the machine, typically measured as the cnc machine’s work envelope (X, Y, and Z coordinate range), is a huge determiner of machine cost. CNC Machines range from tiny in size (small enough to fit on a tabletop) to gigantic (large enough you could drive a truck onto their work area).

The main factors contributing to the overall cost per hour of CNC operations include costs for labor, machine depreciation, material expenses, tooling, energy consumption, and overhead. This guide will help you learn about the cost calculation of CNC machining. What Determines CNC Machining Cost?

machinery cost per hour calculator

According to industry reports, brand new CNC routers can range from ,000 to 0,000 depending on their specifications. The market for used CNC machines shows a broad spectrum of pricing, where well-maintained models can retain up to 70% of their original value.

electrical socket box size

If your project needs electrical boxes or enclosures, and you don’t know what are the main types of electrical enclosures, you need to read this guide, I will tell you 76 types of electrical boxes for your business based on material, mounting types, features, applications, and more. You can also check this infographic to have a quick look:

cnc machine price per hour|machinery cost per hour calculator