cnc machine assembly drawing In this blog post, we will guide you through the process of creating high-quality CNC machine drawings, covering everything from software selection to specific techniques. So grab your . My issue is that the accessory switch power wire came unconnected to the harness. So I do not know where to connect the power wire from my aftermarket stereo. It did come with the constant power connected just not the accessory switch.

0 · schematic diagram of cnc machine

1 · parts made by cnc machine

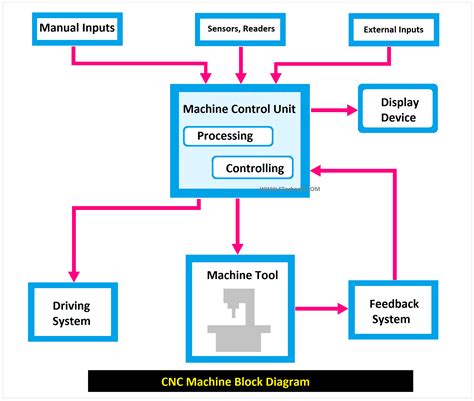

2 · explain Mcu in cnc

3 · diagram of cnc lathe machine

4 · cnc mill parts diagram

5 · cnc machine assembly process

6 · block diagram of nc machine

7 · block diagram of cnc machine

The proper installation and use of junction boxes are paramount for a safe and efficient electrical system in your home. By understanding the function of junction boxes, using the right tools and materials, following a step-by-step .

CNC machining drawings are the blueprints for precisely manufactured operations that ensure the accuracy and efficiency at the core of the process. These intricate drawings determine the dimensions, shape, and .

In this blog post, we will guide you through the process of creating high-quality CNC machine drawings, covering everything from software selection to specific techniques. So grab your .In this article, we’ll explain when to include a technical drawing (or machining blueprints) in your CNC order and what you need to include to get the most out of part sourcing. This article also includes technical drawing guidelines and best .

Technical drawings are essential for both CNC machining and Rapid Prototyping, as they serve as blueprints for the machines to follow. These drawings give a precise representation of the object that needs to be .

Technical drawings are the instructions that tell a CNC machinist how to make a part. They can be created using CAD software, or they can be hand-drawn. Once the technical drawing is complete, it is saved as a PDF and . From the perspective of mechanical processing and manufacturing, how to cultivate design capabilities and how to draw a good drawing of CNC machining parts? For example, surveying and mapping a .Before the invention of CNC (Computer Numerical Control), machinists relied solely on 2D engineering drawings to determine machining steps and parameters. Manufacturing has come a long way since then, thanks to precise 3D .

Preparing a technical drawing for CNC machining requires attention to detail and a methodical approach. Here are seven simple steps to guide you through the process: Step 1: Define the Objective: Clearly understand the . This guide delves into the basics of machining drawings, their importance, and the essential elements of a CNC machining drawing. You will also learn why you need to prepare a technical drawing when sourcing parts and the importance of . In this guide, I will walk you through the process of creating technical drawings for CNC machining projects, from start to finish. I will cover everything from the basics of drawing software to more advanced techniques such as 3D rendering.

CNC machining drawings are the blueprints for precisely manufactured operations that ensure the accuracy and efficiency at the core of the process. These intricate drawings determine the dimensions, shape, and tolerances required by CNC machines to manufacture virtually perfect products in high volume.In this blog post, we will guide you through the process of creating high-quality CNC machine drawings, covering everything from software selection to specific techniques. So grab your pencils and let's get started!In this article, we’ll explain when to include a technical drawing (or machining blueprints) in your CNC order and what you need to include to get the most out of part sourcing. This article also includes technical drawing guidelines and best practices from our engineers. Technical drawings are essential for both CNC machining and Rapid Prototyping, as they serve as blueprints for the machines to follow. These drawings give a precise representation of the object that needs to be produced and guide the machine in .

Technical drawings are the instructions that tell a CNC machinist how to make a part. They can be created using CAD software, or they can be hand-drawn. Once the technical drawing is complete, it is saved as a PDF and sent to the CNC machine. The CNC machine reads the PDF and knows how to make the part. From the perspective of mechanical processing and manufacturing, how to cultivate design capabilities and how to draw a good drawing of CNC machining parts? For example, surveying and mapping a simple CNC machined part, helping others to disassemble and draw the part drawing from the component drawing, etc.

schematic diagram of cnc machine

Before the invention of CNC (Computer Numerical Control), machinists relied solely on 2D engineering drawings to determine machining steps and parameters. Manufacturing has come a long way since then, thanks to precise 3D modeling . Preparing a technical drawing for CNC machining requires attention to detail and a methodical approach. Here are seven simple steps to guide you through the process: Step 1: Define the Objective: Clearly understand the purpose of the part and its intended function. This guide delves into the basics of machining drawings, their importance, and the essential elements of a CNC machining drawing. You will also learn why you need to prepare a technical drawing when sourcing parts and the importance of . In this guide, I will walk you through the process of creating technical drawings for CNC machining projects, from start to finish. I will cover everything from the basics of drawing software to more advanced techniques such as 3D rendering.

when to use metal junktion box

CNC machining drawings are the blueprints for precisely manufactured operations that ensure the accuracy and efficiency at the core of the process. These intricate drawings determine the dimensions, shape, and tolerances required by CNC machines to manufacture virtually perfect products in high volume.In this blog post, we will guide you through the process of creating high-quality CNC machine drawings, covering everything from software selection to specific techniques. So grab your pencils and let's get started!

In this article, we’ll explain when to include a technical drawing (or machining blueprints) in your CNC order and what you need to include to get the most out of part sourcing. This article also includes technical drawing guidelines and best practices from our engineers.

wheels within wheels find and activate junction box

parts made by cnc machine

Technical drawings are essential for both CNC machining and Rapid Prototyping, as they serve as blueprints for the machines to follow. These drawings give a precise representation of the object that needs to be produced and guide the machine in . Technical drawings are the instructions that tell a CNC machinist how to make a part. They can be created using CAD software, or they can be hand-drawn. Once the technical drawing is complete, it is saved as a PDF and sent to the CNC machine. The CNC machine reads the PDF and knows how to make the part. From the perspective of mechanical processing and manufacturing, how to cultivate design capabilities and how to draw a good drawing of CNC machining parts? For example, surveying and mapping a simple CNC machined part, helping others to disassemble and draw the part drawing from the component drawing, etc.

Before the invention of CNC (Computer Numerical Control), machinists relied solely on 2D engineering drawings to determine machining steps and parameters. Manufacturing has come a long way since then, thanks to precise 3D modeling .

explain Mcu in cnc

Get the best deals for Winnie the Pooh Metal Lunch Box at eBay.com. We have a great online selection at the lowest prices with Fast & Free shipping on many items!

cnc machine assembly drawing|explain Mcu in cnc