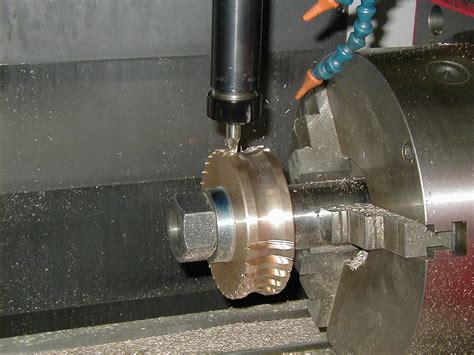

4 axis cnc milling parts The key components of a 4-axis CNC machine include the machine bed, spindle, chuck or collet, and the rotary axis. The spindle holds the cutting tool and moves along the X, Y, and Z axes, while the rotary axis rotates the workpiece. Discover five excellent places where you can learn metal fabrication skills and techniques. Join Fabville today. Visit our site for more details.These online courses are designed to provide the basic knowledge necessary to get started as a CNC machine operator or CNC machinist. They offer an introduction to basic CNC machine operation, proper machine safety, and fundamental machining processes.

0 · what is 4 axis cnc

1 · hobby 4 axis cnc machine

2 · cnc 4th axis for sale

3 · 4th axis rotary cnc

4 · 4 axis hobby cnc

5 · 4 axis desktop cnc mill

6 · 4 axis cnc mill cost

7 · 4 axis cnc for sale

$12.00

4-axis CNC machining is a versatile process for machining different components ranging from small electronic parts to large aerospace machined parts. They are also suitable for handling various CNC machining materials .What is 4-axis CNC Machining? 4-axis CNC machining is a type of advanced machining that uses CNC machines with an extra rotating axis. This rotation lets you work on four sides of a part while it remains clamped in one position, .The key components of a 4-axis CNC machine include the machine bed, spindle, chuck or collet, and the rotary axis. The spindle holds the cutting tool and moves along the X, Y, and Z axes, while the rotary axis rotates the workpiece.Key components of a 4-axis CNC machine include: Various motors and actuators control movement along each axis. Additionally, specialized fixtures such as 4th-axis tombstones or vises can be used for efficient workholding during .

4-axis CNC machining is a versatile process for machining different components ranging from small electronic parts to large aerospace machined parts. They are also suitable for handling various CNC machining materials and part sizes.What is 4-axis CNC Machining? 4-axis CNC machining is a type of advanced machining that uses CNC machines with an extra rotating axis. This rotation lets you work on four sides of a part while it remains clamped in one position, requiring only a single setup. 4-axis CNC machining allows for greater precision and versatility in the production of complex parts. The fourth axis, also known as the A-axis, enables the machine to rotate the part being worked on, allowing for more intricate cuts and contours. 4th Axis machining is an interesting and important sub-part of the CNC milling world. Haas actually got it’s start building a 4th axis before it ever built entire CNC machines (pictured on the right). This is an article series to help beginners understand how and why a 4th Axis is used on CNC Mills.

The key components of a 4-axis CNC machine include the machine bed, spindle, chuck or collet, and the rotary axis. The spindle holds the cutting tool and moves along the X, Y, and Z axes, while the rotary axis rotates the workpiece.Key components of a 4-axis CNC machine include: Various motors and actuators control movement along each axis. Additionally, specialized fixtures such as 4th-axis tombstones or vises can be used for efficient workholding during machining operations. The benefits of 4-axis CNC machining are numerous, but here are two most important: axis CNC machining utilizes Computer Numerical Control (CNC) technology to make intricate parts. Unlike 3-axis CNC machines (which move along X, Y and Z axes), 4-axis machines add an extra rotational A-axis. This provides greater flexibility in machining operations. The A-axis enables workpiece rotation around X-axis.More specific, milling on a 4-axis CNC machine gives us the possibility to machine holes and cavities at different angles. In addition, we can mill components while they are.

4 Axis CNC machines find widespread use across various industries, underscoring their versatile applications: Aerospace: The production of parts such as turbines, propellers, and antennas that require complex geometries and high precision is .3, 4 and 5 axis CNC machining for both low and high complexity milling parts. Standard, Swiss type and multitasking turn-mills for all types of turned parts. EDM, wire-cut, cylindrical and surface grinding, lapping, laser marking and more. Aluminum, . 4-axis CNC machining is a versatile process for machining different components ranging from small electronic parts to large aerospace machined parts. They are also suitable for handling various CNC machining materials and part sizes.

What is 4-axis CNC Machining? 4-axis CNC machining is a type of advanced machining that uses CNC machines with an extra rotating axis. This rotation lets you work on four sides of a part while it remains clamped in one position, requiring only a single setup.

what is 4 axis cnc

4-axis CNC machining allows for greater precision and versatility in the production of complex parts. The fourth axis, also known as the A-axis, enables the machine to rotate the part being worked on, allowing for more intricate cuts and contours. 4th Axis machining is an interesting and important sub-part of the CNC milling world. Haas actually got it’s start building a 4th axis before it ever built entire CNC machines (pictured on the right). This is an article series to help beginners understand how and why a 4th Axis is used on CNC Mills.The key components of a 4-axis CNC machine include the machine bed, spindle, chuck or collet, and the rotary axis. The spindle holds the cutting tool and moves along the X, Y, and Z axes, while the rotary axis rotates the workpiece.

Key components of a 4-axis CNC machine include: Various motors and actuators control movement along each axis. Additionally, specialized fixtures such as 4th-axis tombstones or vises can be used for efficient workholding during machining operations. The benefits of 4-axis CNC machining are numerous, but here are two most important: axis CNC machining utilizes Computer Numerical Control (CNC) technology to make intricate parts. Unlike 3-axis CNC machines (which move along X, Y and Z axes), 4-axis machines add an extra rotational A-axis. This provides greater flexibility in machining operations. The A-axis enables workpiece rotation around X-axis.More specific, milling on a 4-axis CNC machine gives us the possibility to machine holes and cavities at different angles. In addition, we can mill components while they are. 4 Axis CNC machines find widespread use across various industries, underscoring their versatile applications: Aerospace: The production of parts such as turbines, propellers, and antennas that require complex geometries and high precision is .

hobby 4 axis cnc machine

cnc 4th axis for sale

4th axis rotary cnc

Get a fast quote for custom parts from eMachineShop. Upload your CAD file for .

4 axis cnc milling parts|4th axis rotary cnc