electrical box plaster ring set back My interpretation of the Code is that the device yoke should be as close, if not making mechanical contact with the box or plaster ring. To ensure a proper ground and to be . Read this OEM Manufacturing Case Study of a sheet metal stamping parts for machine tools. View the action plan, background info, photos, and final results.

0 · single gang plaster ring dimensions

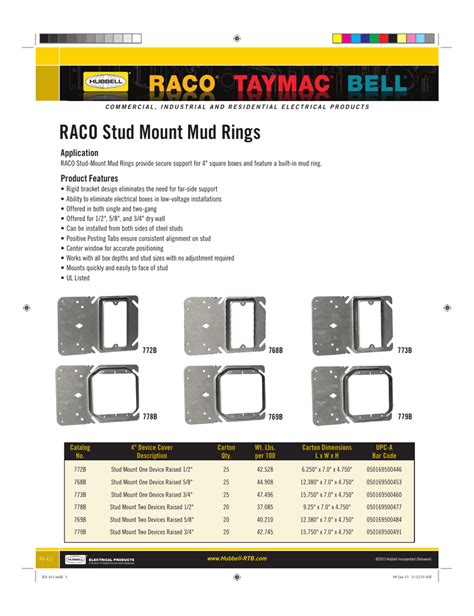

1 · single gang plaster ring

2 · mud ring size chart

3 · electrical outlet mud ring

4 · adjustable plaster ring

5 · 4 11 16 plaster ring

6 · 3 gang flat plaster ring

7 · 1 3 4 plaster ring

On-demand CNC machining service for rapid prototyping and production parts, through a network of specialized, experienced and thoroughly vetted local and global CNC machine shops. CNC machine all types of parts, from simple “as machined” workholdings to complex geometries.

In walls or ceilings with a surface of concrete, tile, gypsum, plaster, or other noncombustible material, boxes employing a flush-type cover or faceplate shall be installed so that the front .Installations within or behind a surface of concrete, tile, gypsum, plaster, or other .The plaster ring shall be set back from the finished surface at least 1∕4 inch. C: The front edge of the box, plaster ring, extension ring, or listed extender shall . My interpretation of the Code is that the device yoke should be as close, if not making mechanical contact with the box or plaster ring. To ensure a proper ground and to be .

single gang plaster ring dimensions

single gang plaster ring

If the box is set back into the wall, snap off the ears at the score marks and put them on the screws. Use one, two or more as necessary to get the device tight to the box and . Installations within or behind a surface of concrete, tile, gypsum, plaster, or other noncombustible material, including boxes employing a flush-type cover or faceplate, shall be .

Installation within walls or ceilings finished with a noncombustible material must have the front edge of the box, plaster ring, extension ring, or listed extender set back no more than ¼ in. from the finished surface (Fig. 1).

Installations within or behind a surface of concrete, tile, gypsum, plaster, or other noncombustible material, including boxes employing a flush-type cover or faceplate, shall be made so that the .

face of concrete, tile, gypsum, plaster, or other noncombustible material, boxes employing a flush-type cover or faceplate shall be installed so that the front edge of the box, plaster ring, extension ring, or listed extender . Installations within or behind a surface of concrete, tile, gypsum, plaster, or other noncombustible material, including boxes employing a flush-type cover or faceplate, shall be made so that the front edge of the box, plaster . In walls or ceilings with a surface of concrete, tile, gypsum, plaster, or other noncombustible material, boxes employing a flush-type cover or faceplate shall be installed .

In walls or ceilings with a surface of concrete, tile, gypsum, plaster, or other noncombustible material, boxes employing a flush-type cover or faceplate shall be installed so that the front edge of the box, plaster ring, extension ring, or listed extender will not be set back of the finished surface more than 6 mm (1⁄4 in.).

The plaster ring shall be set back from the finished surface at least 1∕4 inch. C: The front edge of the box, plaster ring, extension ring, or listed extender shall not be set back of the finished surface more than 1∕4 inch. D: The front edge of the box must be flush with the finished surface. My interpretation of the Code is that the device yoke should be as close, if not making mechanical contact with the box or plaster ring. To ensure a proper ground and to be electrically safe from combustible materials. If the box is set back into the wall, snap off the ears at the score marks and put them on the screws. Use one, two or more as necessary to get the device tight to the box and at the correct position relative to the finished wall. Installations within or behind a surface of concrete, tile, gypsum, plaster, or other noncombustible material, including boxes employing a flush-type cover or faceplate, shall be made so that the front edge of the box, plaster ring, extension ring, or listed extender will not be set back of the finished surface more than 6 mm (1∕4 in.).

Installation within walls or ceilings finished with a noncombustible material must have the front edge of the box, plaster ring, extension ring, or listed extender set back no more than ¼ in. from the finished surface (Fig. 1).Installations within or behind a surface of concrete, tile, gypsum, plaster, or other noncombustible material, including boxes employing a flush-type cover or faceplate, shall be made so that the front edge of the box, plaster ring, extension ring, or listed extender will not be set back of the finished surface more than 6 mm (1 / 4 in.). Your box should be set back no more than 1/4" for drywall per article 314.20. If they are set back further then you need to install an "add a depth" ring --It is a plastic or metal device that extends the box out to the surface of the sheetrock.

mud ring size chart

face of concrete, tile, gypsum, plaster, or other noncombustible material, boxes employing a flush-type cover or faceplate shall be installed so that the front edge of the box, plaster ring, extension ring, or listed extender will not be set back of the finished surface more than 6 mm (1⁄4 in.).

Installations within or behind a surface of concrete, tile, gypsum, plaster, or other noncombustible material, including boxes employing a flush-type cover or faceplate, shall be made so that the front edge of the box, plaster ring, extension ring, or listed extender will not be set back of the finished surface more than 6 mm (1∕4 in.).In walls or ceilings with a surface of concrete, tile, gypsum, plaster, or other noncombustible material, boxes employing a flush-type cover or faceplate shall be installed so that the front edge of the box, plaster ring, extension ring, or listed extender will not be set back of the finished surface more than 6 mm (1⁄4 in.).

The plaster ring shall be set back from the finished surface at least 1∕4 inch. C: The front edge of the box, plaster ring, extension ring, or listed extender shall not be set back of the finished surface more than 1∕4 inch. D: The front edge of the box must be flush with the finished surface.

My interpretation of the Code is that the device yoke should be as close, if not making mechanical contact with the box or plaster ring. To ensure a proper ground and to be electrically safe from combustible materials. If the box is set back into the wall, snap off the ears at the score marks and put them on the screws. Use one, two or more as necessary to get the device tight to the box and at the correct position relative to the finished wall. Installations within or behind a surface of concrete, tile, gypsum, plaster, or other noncombustible material, including boxes employing a flush-type cover or faceplate, shall be made so that the front edge of the box, plaster ring, extension ring, or listed extender will not be set back of the finished surface more than 6 mm (1∕4 in.). Installation within walls or ceilings finished with a noncombustible material must have the front edge of the box, plaster ring, extension ring, or listed extender set back no more than ¼ in. from the finished surface (Fig. 1).

Installations within or behind a surface of concrete, tile, gypsum, plaster, or other noncombustible material, including boxes employing a flush-type cover or faceplate, shall be made so that the front edge of the box, plaster ring, extension ring, or listed extender will not be set back of the finished surface more than 6 mm (1 / 4 in.). Your box should be set back no more than 1/4" for drywall per article 314.20. If they are set back further then you need to install an "add a depth" ring --It is a plastic or metal device that extends the box out to the surface of the sheetrock. face of concrete, tile, gypsum, plaster, or other noncombustible material, boxes employing a flush-type cover or faceplate shall be installed so that the front edge of the box, plaster ring, extension ring, or listed extender will not be set back of the finished surface more than 6 mm (1⁄4 in.).

Stamping your parts from stainless steel, aluminum, HSLA, Steel, copper, and other metals demands precision. Our ISO 9001 registered quality system assures you defect-free stamped metal parts with the tolerances you need and at high volume production rates.

electrical box plaster ring set back|mud ring size chart