sheet metal spot weld Spot welding is a type of resistance welding used to join sheet metal by applying pressure and passing an electric current through the joined materials. In the spot welding process, the heat required to join two or more pieces of metal . Underground junction box enclosures provide cutting-edge NEMA 6P/ IP68 options that offer unparalleled protection in the most demanding conditions.

0 · what is resistance spot welding

1 · what is a spot welder

2 · spot welding current and voltage

3 · spot welding current

4 · spot welding at home

5 · how to spot weld 18galsheetmetal

6 · electrode for spot welding

7 · different types of spot welding

$82.71

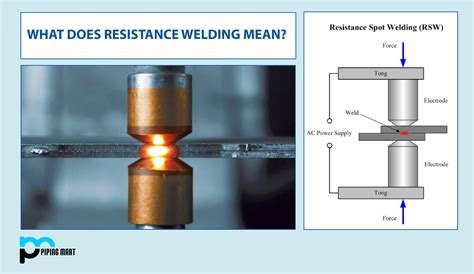

Spot welding is a type of resistance welding used to join sheet metal by applying pressure and passing an electric current through the joined materials. In the spot welding process, the heat required to join two or more pieces of metal .Resistance Spot Welding is the joining of overlapping pieces of metal by applying pressure and electrical current. These joints created by resistance spot welding form a “button” or “fused nugget.” Resistance spot welds are found typically on . Spot welding is commonly used to weld sheet metal. It’s a straightforward process, but there are many ways that things can go wrong if you don’t have spot welding experience. This article will teach you the basics of . TOABLEVEL Air Spot Weld Drill Pneumatic Sheet Metal Drill For Remover Dent Fix W/Hook Drills With 5/16 1/4 Inch Bits For Car Welding Spot Sheet Metal Steel Panel Repair Kit With Four Drill Bits. dummy.

Spot welding, or resistant spot welding, is one of the most common forms of welding used in the precision sheet metal fabrication industry. It’s considered a sheet metal fabrication “staple.” Spot welding allows flat materials to be connected without .The process of spot welding sheet metal fabrications is quite simple it is basically harnessing the heat generated by the resistance to electrical current flow at the interface/joint of two separate pieces of sheet metal. At V&F Sheet Metal we can spot weld mild steel, Zintec, galvanised steel and stainless steel in gauges from 0.7mm to 3mm .

SPOT WELDING DRILL BIT -- Cobalt-containing automotive sheet metal auto repair removal spot welding drill bit, car repair and dismantling plated welding spot drill bit. EXCELLENT MATERIAL -- high-quality cobalt-containing M35 bar material is used, which has good rigidity, strong wear resistance, and can carry high-speed and high-efficiency .This portable, air-cooled spot welder makes quick, strong spot welds without having to install a 240 volt outlet. Welds uncoated mild, galvanized or stainless sheet steel to 1/8 in. combined thickness (mild steel), two pieces of 20 gauge (galvanized). The spot welder has 6 in. tongs lock firmly onto materials. Portable, air-cooled

honda precision parts manufacturing bukit indah

To most manufacturers, spot welding is the most economical way to join two pieces of sheet metal. While joining sheet metal is the most common use for the process, resistance welding (RW) equipment actually can be used for a large variety of joining and heat-treating projects, some of which are not so well-known. Resistance Welding Annealing

Talking to people about resistance spot welding (RSW) of coated steel is like talking to people about which automotive manufacturer is the best; everyone has an opinion. . Then a final weld sequence forms the nugget. This technique works best for sheet metal to 12 gauge. Pulsation: This sequence, typically used for sheet metal 11 gauge and .A portable spot welder. Spot welding (or resistance spot welding [1]) is a type of electric resistance welding used to weld various sheet metal products, through a process in which contacting metal surface points are joined by the heat obtained from resistance to electric current.. The process uses two shaped copper alloy electrodes to concentrate welding current into a .Spot welds work best for low carbon steels. Spot welds of alloy steels with high carbon content tend to be brittle and can crack easily. Aluminium sheets can be joined by spot welds due to their low melting point compared to copper, which is the material of the electrodes. Spot welds are most practical for joining metal sheets that are up to 3 .

Eastwood Axial Clamp Spot Weld Jaws for Auto Body Sheet Metal Steel Construction . Visit the Eastwood Store. 4.7 4.7 out of 5 stars 8 ratings. .99 $ 33. 99

All of these methods will remove spot welds from sheet metal panels. However, only the spot weld cutter and spot weld drill will allow you to remove the weld without damaging the other panel. In the long run, the higher price of these tools will be worth the time they save in terms of the removal process and being able to reuse the panels. . Spot weld cutter reduces the need to pry open and break welds, with double-sided blades for twice the efficiency. The perfect tool for removing spot-welded panels or sheet metal without distorting the metal or damaging . A pair of electrodes simultaneously clamps the work pieces together and delivers the electrical current needed to make the weld. sciencing.com , spot welding aluminum is common as the metal is replacing .

Galvanized sheet metal does no spot weld easy. Strip off the galvanize coating at the weld points and try again. Or find some clean sheet metal or shipping band strap for another test. Reply . 01-04-2022 #3. Continuum. . In sheet metal fabrication, spot welding is often utilized for creating seams, joints, and connections in various products, ranging from household appliances to industrial equipment, where precision and speed are crucial. Electronics and Consumer Goods.Spot welding involves welding two metal sheets together by using a high electric current. To prevent the two sheets from shaking or moving about, they need to be clamped. As such, the second step is to clamp the two sheets of aluminum together. Step Three: Place Two Steel Sheets On Both Aluminum Sheets.

Spot Weld Cutter Set Double Sided 14 Pcs,3/8" HSS Spot Weld Cutter Remover Drill Bits Hex Sheet Metal Hole Cutter Remover Kit for Power Drill Spot Welding, by NAKAO Spot Weld Cutter Set JESTUOUS 5-pack 3/8 Inch HSS Remover Welding Metal .

Spot Welding Sheet Metal with TIG Welder. A TIG welder is the most powerful type of welder that you can use for spot welding sheet metal. It’s also the most expensive type of welder. It can weld the thinnest of metals and has the ability to work at very high temperatures. Its primary usage is in welding auto body and sheet metal. Spot welding is usually used to join a panel of overlapping sheet metal, parts that are usually 3mm thick. The ration of thickness should not exceed 3.1mm. This is because the strength of the joints depends on the number and size of the weld. Thus, spot welding diameters go from 3mm to .

My demonstration using a Lenco Spot Welder. (LencoSpot Welder), (Spot Welding sheet metal), (patch panel spot welder), (auto body spot welder). My demonstrat. Spot welding is a metal joining process that utilizes pressure and heat to join the overlapping workpieces. It is also familiar with the name Resistance Spot welding among the manufacturers. . Prolean offers high-quality welding services and sheet metal services with automated spot welding machines from engineers and operators with more than .

Sheet Metal Spot Welding Machine Double-sided Spot Welder Car Repair Tool. Opens in a new window or tab. Brand New. 8.99 to 4.99. jewelry-business-machine (69) 94.7%. Buy It Now +3.00 shipping. from China. Portable 80A 600W Electric Spot Welder Platinum Gold Silver Welding Machine NEW. To achieve proper spot welds on thin sheet metal, several steps should be followed. Firstly, the metal surfaces should be cleaned to remove any dirt, oil, or debris that may affect the weld quality. Then, the exact locations for the spot welds should be marked for accuracy during the welding process. The appropriate drill bit size, typically 1/ .

what is resistance spot welding

EEEKit Spot Weld Cutter Kit, Sheet Metal Hole Cutter, Punch Remover Panel Separator for Power Drill Welding Auto Body Work Tool, 3/8 Inch Drill Bit Tools, 9 Pieces . Visit the EEEKit Store. 4.5 4.5 out of 5 stars 1,062 ratings. .99 $ 15. 99. Get Fast, Free Shipping with Amazon Prime.

homedepot metal junction boxes

what is a spot welder

spot welding current and voltage

Rubber bands connect to the brackets on your braces and can be positioned in many different conformations. They’re attached and secured using small metal hooks on the bracket.

sheet metal spot weld|different types of spot welding