welding thin sheet metal stick welder Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc . Premium Tool and Socket Carry Case – USA-Made Small Hard Plastic Tool Box – Ideal Screw Organizer, Small Tools, Sockets, and MoreShopSabre is home to the most durable and reliable American-made CNC machines. Browse ShopSabre today and find your ideal CNC router or plasma.

0 · welding thin metal to thick

1 · welding stainless steel sheet metal

2 · welding 20 gauge sheet metal

3 · mig welding thin metal videos

4 · mig welding thin metal settings

5 · best welding for thin metal

6 · best welder for thin metal

7 · arc welding automotive sheet metal

There are a lot of ways to incorporate trellis in your space through more subtle accents like furniture, room dividers, cabinet doors, wallpapers, linens, and accessories. Installing a wood trellis in your space might see daunting.

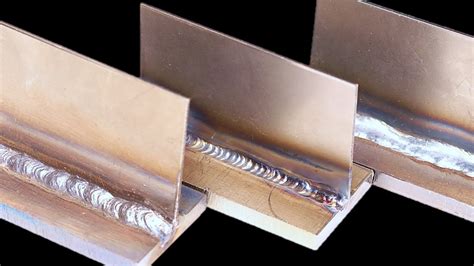

To create a good connection between your metal sheets, setup is most important. Stick welding is, generally speaking, a blunt welding process compared to MIG or TIG welding. And if you have the full range of process to choose from, I would refer you to either TIG for thinner sheets of metal, or MIG welding for . See more

As there are a couple of options, my recommendation would be either an E6011 or E6013rod. Advantage of these electrodes are the high cellulose content in the coating, which . See moreWelding sheet metal DC electrode negative (DCEN) is the best setting due to the higher deposition rate. And DCEP has a deeper penetration into the base material, which we . See moreIt is a bit more tricky to stick weld sheet metal, especially for thinner sheets, compared to the alternatives TIG welding and MIG Welding. However I hope the article encouraged you to give it a shot, as it is definitely possible when setup correctly. Most likely, . See more Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc .

Stick welding gives good results from 1/8″ thick metal and up, but it is not the ideal process for thinner workpieces. After reading this article, you will learn everything you need to get better results. Plus, two alternative ways to .

Can a stick welder weld thin sheet metal? Find out the limitations and the minimum thickness you can arc weld and the best methods of welding sheet metals. How To Weld Thin Metal With A Stick Welder? [The Best Guide] Written by Kaosar Ahmed in Stick Welding Last Updated April 22, 2022. The first time you weld, it is natural to ask how to weld thin metal with a stick welder. .

adding electrical drop house junction box

welding thin metal to thick

thin metal welding tricks that not all know. why didn't the welder tell this secretThis is a square tube welding technique, especially how to weld thin squar. How to weld thin gauge steel similar to car body panel, down to .8mm or 1/32 of an inch thick with arc or stick welder.DisclaimerDue to factors beyond the c. 0 How to Weld Thin Metal: A Step-By-Step Guide (2024) Last Updated on Jan 03 2024. Working using thinner metal sheets is complicated. Excess heat may lead to burnout. The filler metal is the material that melts into the weld and fills the gap between the two pieces being joined. MIG welding simplifies the feeding of filler metal, making the welder’s job easier. While the specific material may not be critical, the form of the filler metal is important when working with thin sheet metal. 3. Adjust the Torch .

Each has its ups and downs and favored applications, but when it comes to thin metal welding, welders typically turn to MIG welding and TIG welding. TIG Welding 20ga Thin Metal. . Stick Welding Thin Metal. . TIG welding thin sheets will require a smaller diameter, .020, .040, and 1/16-inch ceriated or thoriated tungsten. . The Hobart Handler 140 MIG Welder is my top choice because of its versatility and user friendly interface. It is capable of welding thin sheet metals because of its low minimum amperage range and has a smooth and stable arc. It is ideal for hobby welders that can complete their sheet metal welding job without requiring a high duty cycle.

Mig Welding Thin Sheet Metal. Mig welding is a popular and straightforward method of welding thin sheet metal. For mig welding, you don’t need much in the way of equipment. You will only need a mig welder and a proper technique for mig welding thin metal. If you are new to welding, start by welding with a low-amperage setting and a small wire . For thin sheet metal welding it can be 30 ampere while for thicker (e.g. 1/8” square groove weld)- it can go up to 220 ampere for example. GMAW-S gives low heat and makes it easy to use in all positions on sheet metal, low carbon steel, low alloy steel, and stainless steel sheet metal from 25 gauge (0.02 inch or 0.5 mm) to 12 gauge (0.1 inches or 2.6 mm).

Then I have to weld the new 20ga patch material to angles and brackets that range from 1/8" to 3/16" thick. So the big problem is welding thin material (20ga) to thicker material (1/4"-3/16"). I'm a pretty good stick welder, a really good gas welder, but don't do mig, and I'm trying to decide if this is doable. Stick Welding Sheet Metal with 6013 rods! Beginner Welding Series! This is the thinnest sheet metal I have ever welded using this process. I'm welding very .

To weld thin sheet metal, . With DCEN, the electrode holder is connected to the negative side (-) connection of the welder. Stick Welding Medium-Thickness Metal. Stick welding is an ideal and cost-effective method for welding medium-thickness mild steel. This process is commonly used for on-field repairs, maintenance, farm work, and hobbyist . For sheet metal welding, welders will typically support flux-cored wires or solid wires as these give you the most control and versatility. The Reboot MIG welder supports both flux-cored and solid wires. . Sheet metal is metal that is processed into thin and flat sheets Trusted Source Sheet metal . you can stick weld sheet metal less than . Stick welding and flux core involve slag, which is a real nuisance on sheet metal. If you can make overlapping joints, don't overlook rivets or solder. Using enough rivets to hold things together while soldering is an age-old technique.

This takes a lot of skill even for an experienced welder. A realistic size sheet metal would be 18-14 gauge with 1/16" 6013 rods. Usually sheet metal is 24 gauge to 1/8" is considered sheet metal and 3/16" and up is considered plate steel. . welding really thin sheet metal (anything below 1/8") with a stick welder is just a way to make . In this video I show how to set up and tig weld thin metal. There are a lot of different steps to take and I try to make it as easy as possible. From how to . Mastering the art of stick welding sheet metal can be a game-changer for both seasoned professionals and DIY enthusiasts. . Uncover the secrets to achieving immaculate welds on thin sheet metals and harness the .6.Try and AVOID welding sheet metal.If you have to weld on it, use that firepower sparingly. Practice your fab skills ; you can bend smaller sections with clamps and a vice, you can drill sheet metal with an inexpensive (3/8") drill, you can get away with tack-welding connections without a final seal-weld, you can rivet sheet metal.

The equipment settings and code of the electrode are both locked in by the welder. On the thin sheet metal, mild steel or stainless, flimsy sheets will shift around. A series of strategically placed tack welds hold the parts rock-solid. . A Tabulated Guide to Stick Welding Various Metal Thicknesses. Topic: Key Points: Additional Details .For the thin material, arc welding becomes the most sophisticated method to weld. When you know how to weld thin metal with arc welder in a proper way, all the risk and fault will be minimized. I hope you already know the secret of arc welding on . MORE: For those who like the things which YouTube doesnt, join us on a free mobile app called Telegram, under "Tractor Hoarders Group Chat", in case we get c.

Weld metal that is too thick will cause you issues as well. To avoid these issues, you will want to weld thin sheet metal with flux core. Welding thin sheet metal with flux core is a great way to produce complex, detailed shapes quickly and efficiently. In this article, you will learn about flux core welding and get tips for successfully using. Stick Welding Thin Steel Does anyone here use 3/32" 6010, 6011, 6013, or 7014 rod to weld 1/8" mild steel? . View Profile View Forum Posts Find Started Threads; Master Welder Join Date Nov 2005 Location Nashville, TN Posts 6,170 Post Thanks / Like Likes (Given) 536 Likes (Received) . you can weld the thin sheet steel like it is 1/4" thick . yes they sell 1/16" or 1.5mm dia rod 6013 is easiest to get. some comes in long length and tends to vibrate when arc first started.. thin metal means joint gaps should be as small as possible. usually tack weld close together hammering joints tight. weld short distances and let metal cool off. try not to weave but travel fast and in straight line. nothing wrong with weaving .

The problem with welding sheet metal or thin gauge steel is that you can easily blow holes in the panel and create a big mess quickly. We decided to give you some tips when welding sheet metal and help you get jump started. . For thinner gauge sheet metal like 18 or 20 gauge we suggest .023 (6mm) wire in your MIG welder. Keep the Stick Out .A fun challenge to test the limits of stick welding thin metal while providing 4 practical tips. Stick welding is great because of the simple equipment, port. Electrode stick-out: A shorter electrode stick-out (e.g., 1/4 to 3/8 inch) is advised for welding thin metal, as it provides better control of the arc and reduces the heat input. B. Tips for welding thin metal with a gasless MIG welder Fuse the thick side without burning through the thin using these techniques for Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW) or Shielded Met.

adhesive metal house numbers

welding stainless steel sheet metal

adjustable electrical boxes for 24 ceiling tile

welding 20 gauge sheet metal

The SL250 is a true 45-degree slant bed CNC lathe with a 10" chuck. It is made for heavy and interrupted cutting with superior part finishes.

welding thin sheet metal stick welder|mig welding thin metal settings