best welding rod for welding sheet metal Compare the differences between 6010, 6011, 6013, 7018 & 7024 welding rods and learn how to choose the right one for your job!

All wood species and composites, laminates, and real wood veneers. Sanded and ready for finish or finished to specification. Boring, slotting, edgebanding, dadoing, carving, moulding, and rotary shaping.

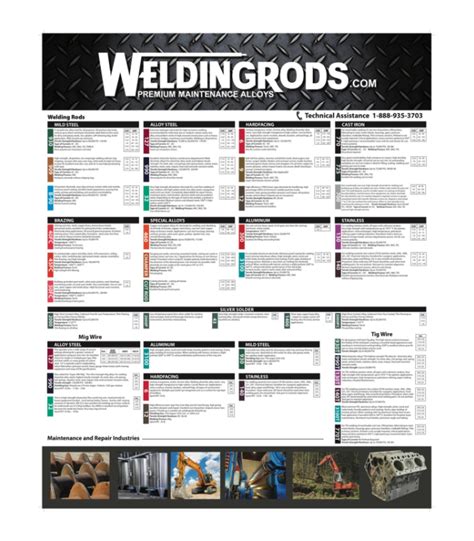

0 · welding rod uses chart

1 · welding rod types chart

2 · welding rod differences chart

3 · welding rod comparison chart

4 · most commonly used welding rods

5 · most common welding rod size

6 · best welding rod for overhead

7 · best all purpose welding rod

For nearly 30 years, Wisconsin Metal Fab has been western Wisconsin’s premier custom metal fabricator. Based in Chippewa Falls, WI, we serve businesses throughout the United States, in industries ranging from defense to truck bodies, oil & gas production, and power generation.

Compare the differences between 6010, 6011, 6013, 7018 & 7024 welding rods and learn how to choose the right one for your job! Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc . In this welding rod chart, you will find over 220 stick electrodes classified according to the American Welding Society (AWS) code. The PDF has 8 sections: Each section covers .6012 is a great rod for home and hobby use. Similarly to 6013, it does not penetrate deep, while producing beautiful uniform beads, which makes it suitable for sheet metal as well as welding art. E6013 is a High Titania Potassium rod .

See our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables.

Compare the differences between 6010, 6011, 6013, 7018 & 7024 welding rods and learn how to choose the right one for your job! Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make. These are the best welding rods for aluminum, pot metal, and galvanized steel. These rods are best for beginners or those who want to do some repairs around the house quickly and easily with no specialized training or equipment required.

In this welding rod chart, you will find over 220 stick electrodes classified according to the American Welding Society (AWS) code. The PDF has 8 sections: Each section covers all AWS-specified electrodes and provides the needed information.

6012 is a great rod for home and hobby use. Similarly to 6013, it does not penetrate deep, while producing beautiful uniform beads, which makes it suitable for sheet metal as well as welding art. E6013 is a High Titania Potassium rod designed for welding sheet metal. It can be run on AC, DCEP and DCEN. If you’re a DIY welder looking for the best all-around welding rods for, look no further than the E6013, E7018, and E7024 electrodes. These welding rods are your go-to options for tackling a range of general welding projects with high success rates. Welding thin metal requires precision and the right tools to ensure strong, durable joints without warping or damaging the material. Selecting the appropriate welding rod is crucial, as it influences the weld’s quality, ease of application, and final appearance. Worry not as here are the 10 best welding rods that you can buy. All welding rods mentioned here are equally good, the difference only lies in price and some feature differences. 1. FORNEY 30705 7018 – Best Welding Rod for Mild Steel: Forney has a large variety of welding rods which makes it fit every customer’s pocket easily.

Stick welding gives good results from 1/8″ thick metal and up, but it is not the ideal process for thinner workpieces. After reading this article, you will learn everything you need to get better results. Plus, two alternative ways to join thin metal with your stick welder. Why is it hard to stick weld thin metal? See our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. Compare the differences between 6010, 6011, 6013, 7018 & 7024 welding rods and learn how to choose the right one for your job! Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

These are the best welding rods for aluminum, pot metal, and galvanized steel. These rods are best for beginners or those who want to do some repairs around the house quickly and easily with no specialized training or equipment required.

welding rod uses chart

welding rod types chart

In this welding rod chart, you will find over 220 stick electrodes classified according to the American Welding Society (AWS) code. The PDF has 8 sections: Each section covers all AWS-specified electrodes and provides the needed information.

6012 is a great rod for home and hobby use. Similarly to 6013, it does not penetrate deep, while producing beautiful uniform beads, which makes it suitable for sheet metal as well as welding art. E6013 is a High Titania Potassium rod designed for welding sheet metal. It can be run on AC, DCEP and DCEN.

If you’re a DIY welder looking for the best all-around welding rods for, look no further than the E6013, E7018, and E7024 electrodes. These welding rods are your go-to options for tackling a range of general welding projects with high success rates.

Welding thin metal requires precision and the right tools to ensure strong, durable joints without warping or damaging the material. Selecting the appropriate welding rod is crucial, as it influences the weld’s quality, ease of application, and final appearance.

Worry not as here are the 10 best welding rods that you can buy. All welding rods mentioned here are equally good, the difference only lies in price and some feature differences. 1. FORNEY 30705 7018 – Best Welding Rod for Mild Steel: Forney has a large variety of welding rods which makes it fit every customer’s pocket easily.

welding rod differences chart

welding rod comparison chart

Wichita Sheet Metal Supply Inc is located in Wichita, Kansas, and was founded in 1983. At this location, Wichita Sheet Metal Supply Inc employs approximately 120 people. This business is .

best welding rod for welding sheet metal|welding rod types chart