mechanics of sheet metal forming pdf This chapter first introduces sheet metal forming processes, including their industrial importance. The principal strain increments in uniaxial loading are analyzed using . Correct fill capacity: The junction box should be large enough to contain the wires. .

0 · types of sheet metal pdf

1 · sheet metal stamping process pdf

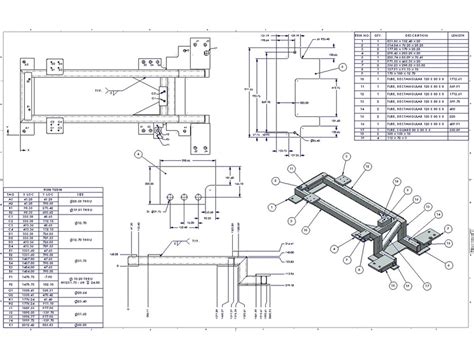

2 · sheet metal fabrication drawings pdf

3 · sheet metal fabrication book pdf

4 · sheet metal drawing pdf download

5 · sheet metal development drawing pdf

6 · sheet metal design standards pdf

7 · sheet metal basics pdf

Get the best deals on Metal Antique Chests when you shop the largest online selection at eBay.com. Free shipping on many items | Browse your favorite brands | affordable prices.

Mechanics of Sheet Metal Forming (Marciniak) Previous ed.: London: Arnold, 1992. Includes index. Material properties -- Sheet deformation processes -- Deformation of sheet in plane stress -- Simplified stamping .sheet metal forming processes. Bending, stretching and drawing of simple shapes are analysed, as are certain processes for forming thin-walled tubing. Where possible, the limits governing .Basic Mechanics. Spring back. Forming limit diagrams. Appendix. Plastic behavior of metals. Spring-back derivation. Developing forming technologies. M. ~ 90 million vehicles produced . Mechanics of sheet metal forming. The basic theory of sheet metal forming in the automotive, appliance and aircraft industries is given. This fills a gap between the descriptive .

This chapter first introduces sheet metal forming processes, including their industrial importance. The principal strain increments in uniaxial loading are analyzed using .

This book is designed to help the engineer understand the principles of metal form-ing and to analyze forming problems – both the mechanics of forming processes and how the properties .Sheet metal forming processes involve a great deal of plastic deformation; these processes include: bending, deep drawing (with a flat-headed punch), stretch forming, and general .Presents the fundamentals of sheet metal forming - bending, stretching, press forming, deep drawing and hydroforming; Shows how deformation, loads and process limits can be .

ME 678 Mechanics of Sheet Metal Forming (3-0-0-6) Description of Material properties: Tensile test, effect of properties on forming. Sheet deformation processes: Uni-axial tension, general .

Mechanics of Sheet Metal Forming Mechanics of Sheet Metal Forming Z. Marciniak The Technical University of Warsaw, Poland J.L. Duncan The University of Auckland, New Zealand S.J. Hu The University of Michigan, USA OXFORD AMSTERDAM BOSTON LONDON NEW YORK PARIS SAN DIEGO SAN FRANCISCO SINGAPORE SYDNEY TOKYO Butterworth .This paper deals with the Abaqus/Explicit implementation of a constitutive model for orthotropic thin sheet metals subjected to forming procedures dominated by stretching and bending effects. The metallic sheet is assumed to behave as an .Mechanics of Sheet Metal Forming This Page Intentionally Left Blank Mechanics of Sheet Metal Forming Z. Marciniak The Technical University of Warsaw, Poland J.L. Duncan The University of Auckland, New Zealand S.J. Hu The University of Michigan, USA OXFORD AMSTERDAM BOSTON LONDON NEW YORK PARIS SAN DIEGO SAN FRANCISCO SINGAPORE .There is a need to understand the mechanics part of the sheet forming processes such as deep drawing, stretch forming, bending, hydroforming, along with basic plasticity. This course will provide such details through theoretical analyses and numerical problems, along with basic concepts in metal forming.

Mechanics of Sheet Metal Forming Mechanics of Sheet Metal Forming Z. Marciniak The Technical University of Warsaw, Poland J.L. Duncan The University of Auckland, New Zealand S.J. Hu The University of Michigan, USA OXFORD AMSTERDAM BOSTON LONDON NEW YORK PARIS SAN DIEGO SAN FRANCISCO SINGAPORE SYDNEY TOKYO Butterworth .The deformation is homogeneous so plane sections remain plane. 7.1 SHEET DRAWING Figure 7.1 illustrates sheet or strip drawing. A force, F, pulls a strip through a pair of wedges. The strip width, w, is much greater than the thickness, t, so the . Mechanics of sheet metal forming Bookreader Item Preview . The basic theory of sheet metal forming in the automotive, appliance and aircraft industries is given. This fills a gap between the descriptive treatments in most manufacturing texts and the advanced numerical methods used in computer-aided-design systems. . Pdf_module_version 0.0. . PDF | Thesis (doctoral)--Luleå University of Technology, 1997. | Find, read and cite all the research you need on ResearchGate. Thesis PDF Available. Mechanics of sheet metal forming: strength .

Mechanics of Sheet Metal Forming This Page Intentionally Left Blank Mechanics of Sheet Metal Forming Z. Marciniak The Technical University of Warsaw, Poland J.L. Duncan The University of Auckland, New Zealand S.J. Hu The University of Michigan, USA OXFORD AMSTERDAM BOSTON LONDON NEW YORK PARIS SAN DIEGO SAN FRANCISCO SINGAPORE .

types of sheet metal pdf

sheet metal stamping process pdf

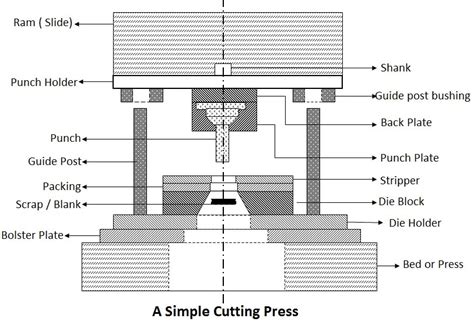

sheet metal forming.pdf - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Sheet metalworking involves cutting and forming thin metal sheets less than 6mm thick using machine presses. The three main sheet metal forming processes are cutting, bending, and drawing. Sheet metal parts can be classified into five categories including singly curved parts .

of sheet metal forming processes, there is a need to improve our knowledge of the basic mechanics of such processes and it will be necessary to check theoretical predictions against carefully controlled experiments.

Mg/Al laminate composites were prepared at 400 ℃ for 15 min through single-pass rolling with reduction ratio from 10 to 27%. The bonding mechanism of the initial bonding stage under low pressure .

Mechanics of Sheet Metal Forming This Page Intentionally Left Blank Mechanics of Sheet Metal Forming Z. Marciniak The Technical University of Warsaw, Poland J.L. Duncan The University of Auckland, New Zealand S.J. Hu The University of Michigan, USA OXFORD AMSTERDAM BOSTON LONDON NEW YORK PARIS SAN DIEGO SAN FRANCISCO SINGAPORE .

In sheet metal at room temperature, rate sensitivity is small, but it can affect necking as strain rates in the neck can become quite high when uniform straining ceases 66 Mechanics of Sheet Metal Forming%PDF-1.4 %âãÏÓ 663 0 obj > endobj 685 0 obj >/Filter/FlateDecode/ID[704E8A5A77AA90E0E45753C1AAABDACC>]/Index[663 39]/Info 662 0 R/Length 112/Prev 3172114/Root 664 . PDF | In the article the changes associated with construction of machines used in die and die-less sheet metal forming have been presented. . Mechanics Zeszyty Naukowe Politechniki Rzeszowskiej .The basic theory of sheet metal forming in the automotive, appliance and aircraft industries is given. This fills a gap between the descriptive treatments in most manufacturing texts and the advanced numerical methods used in computer .

It is a method of producing contours in sheet metal. Thinning and strain hardening is inherent in the process. Stretch forming is a sheet metal forming process in which the sheet metal is intentionally stretched and simultaneously bent to have the shape change. It is a type of cold drawing. Stress-induced is mainly tensile. Coining:Semantic Scholar extracted view of "The mechanics of sheet metal forming" by Z. Marciniak et al. . Has PDF. Author. More Filters. More Filters. Filters. Forming Limits of Sheet Metal. D. Banabic. Materials Science, Engineering. 2000; Besides the flow curve and plastic anisotropy, the formability of a material includes the capability to .

1. Stress and strain 2. Plasticity 3. Strain hardening 4. Plastic instability 5. Temperature and strain-rate dependence 6. Work balance 7. Slab analysis and friction 8. Friction and lubrication 9. Upper-bound analysis 10. Slip-line field analysis 11. Deformation zone geometry 12. Formability 13. Bending 14. Plastic anisotropy 15. Cupping, redrawing and ironing 16. Forming limit .Download book PDF. Mechanics of Sheet Metal Forming Download book PDF. Overview Editors: Donald P. Koistinen 0, . This volume records the proceedings of an international symposium on "ME CHANICS OF SHEET METAL FORMING: Material Behavior and Deformation Analysis." It was sponsored and held at the General Motors Research Labora tories on .Mechanics of Sheet Metal Forming Mechanics of Sheet Metal Forming Z. Marciniak The Technical University of Warsaw, Poland J.L. Duncan The University . Mechanics of Sheet Metal Forming Mechanics of Sheet Metal Forming [PDF] Related documentation. Studies on the Cretaceous Ammonites from Hokkaido and Saghalien-Ⅷ .

mechanics of sheet forming in this manner. It does, however, draw on the earlier work of, for example, Swift, Sachs, Fukui, Johnson, Mellor and Backofen although . sheet metal forming processes. Bending, stretching and drawing of simple shapes are analysed, as are certain processes for forming thin-walled tubing. Where possible, theSheet Metal Forming. p. . This book helps the engineer understand the principles of metal forming and analyze forming problems - both the mechanics of forming processes and how the properties of metals interact with the processes. The first third of the book is devoted to fundamentals of mechanics and materials; the middle to the analyses of .Metal Forming: Mechanics and Metallurgy CHAPTER 1-3 - Free download as Word Doc (.doc), PDF File (.pdf), Text File (.txt) or read online for free. Solution Manual 3rd Ed.

Deep drawing is a metal forming process where a flat sheet is pressed into a die cavity by a punch to create cylindrical or box-shaped parts like beverage cans, pots, and pans. The mechanics of deep drawing involve the sheet first being bent over the punch and die corners before metal is drawn into the die opening to form the walls. As the flange moves inward, the .In recent years, enormous progress has been made in the analysis of forming of complex shapes using finite element methods; many engineers are now using these systems to analyse forming of intricate sheet metal parts. There is, however, a wide gulf between the statement of the basic laws governing deformation in sheet metal and the application of

sheet metal fabrication drawings pdf

sheet metal fabrication book pdf

Types of CNC machines: There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters. Each machine has its own advantages and disadvantages depending on the material, shape, and complexity of the workpiece.

mechanics of sheet metal forming pdf|sheet metal fabrication drawings pdf