radius bender sheet metal I built a simple sheet metal bender out of scraps I had laying around. Necessity being the mother that it is, I had to bend a panel for the van that was just under 39 inches long and the 3-in-1 is too short to do that. This is . IP68 Waterproof Junction Box Outdoor, 4 Way Underground Electrical Junction Box, Plastic Electrical Box with Terminal Block, Suitable for LED Landscape Lighting, Garden Lights, Solar Power and More

0 · sheet metal radius calculator

1 · sheet metal inside bend radius

2 · sheet metal bend deduction chart

3 · maximum thickness sheet metal bending

4 · calculate bend radius sheet metal

5 · bending steel plate minimum radius

6 · bend radius sheet metal chart

7 · 304 stainless minimum bend radius

30 Gallon Lockable Resin Deck Box, Waterproof & UV-Resistant Outdoor .

sheet metal radius calculator

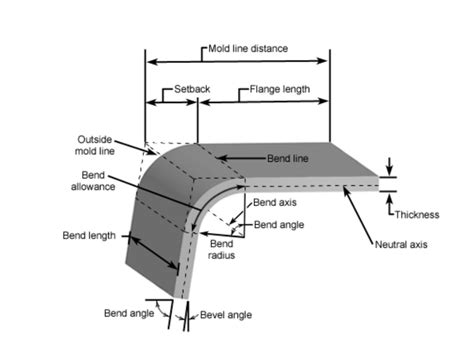

Just a few are the forming method (air forming, bottoming, or coining), the type of bend (sharp, radius, or profound radius bends), the tooling you are using, and the multibreakage of the workpiece during large-radius . 2. Sheet Metal Bend Radius Chart. A sheet metal bend radius chart is a valuable tool that provides engineers and fabricators with essential information. It typically lists various materials and their corresponding recommended bend radii. Think of it as a cheat sheet for ensuring your metal sheets stay intact during the bending process. 3. The . To achieve the correct sheet metal bend radius, it is crucial to use proper techniques, equipment, and tooling. Using the appropriate press brake and metal bending tools and following proper air bending or metal bending .

I built a simple sheet metal bender out of scraps I had laying around. Necessity being the mother that it is, I had to bend a panel for the van that was just under 39 inches long and the 3-in-1 is too short to do that. This is .

Metal bending brake, radius brake or radius brakes on floor stands from Mittler Bros. Blue – 6 foot or 8 foot models with radius tube, . Sheet Metal Brakes ; Radius Brakes; Radius Brakes. 8 Items . Show. per page. Sort By. Set Descending Direction. 48" Econo Radius Brake .

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at . ER3 Three-Station Edge Roller, 0-90° Bending Angle, Large Radius Sheet Metal Bead Roller Bender, Adjustable for Making 5/8" to 4" Bends in 29 to 22-Gauge Steel, for Bending Metal Roofing Materials Customer reviews 3 How to implement the industry standard sheet metal bend radius. 3.1; 3.2 Your Partner in Precision Sheet Metal Design; 4 Sheet Metal Part Design for Manufacturing Tip. 4.1 BENDS; 5 Applying a Sheet Metal Bend Radius FAQ. 5.0.1 What is the common mistake customers make when designing the bend radius for sheet metal parts?

The Wuko Uni Bender can be used for bending and forming in sheet metal fabrication Features: The 'longer' brother of the Wuko Uni Bender 2204For bending straight sheets and radius up to 90°.Improved version of the 2200 & 2202 models: narrower, yet still equipped with 4 rollers and more efficient in bending common sheet metal, notably zinc and .

In conclusion, sheet metal bend radius plays a crucial role in determining the quality and integrity of the bends. It is essential to consider factors such as material thickness, bend angle, and type of machinery used to achieve optimal results. By adhering to the recommended bend radius values and using the appropriate tooling, you can avoid . The minimum sheet metal bending height should be calculated as 2 times the thickness of the sheet metal plus the bending radius, i.e., H ≥ 2t + R. As illustrated in the accompanying figure, if the bending height is too low, the sheet metal is prone to deformation and twisting during the bending process , leading to suboptimal part shape and .

Fig.: Bending specs for 0.040” 5052 Aluminum. Bend Length. The bend length, or width of the flange, is dependent on, wait for it, the material properties: For the 304 Stainless in the previous example, the maximum length is 36” while a thinner, more ductile material like the the 5052 aluminum can easily be bent all the way up to the max part size of 44”. The bend’s outer edge would crack if it exceeds the minimum bend radius which is typically specified according to the metal sheet thickness (t) like 1t, 2t, 3t etc. A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. Sheet metal layout isn't hard. You just do it right, and it works. Draw the part with the OD of the bends marked correctly. Now, using a bend allowance table and the metal thickness with bend radius to enter the table, SUBTRACT the allowance from the OD, once for each bend. If it's tab with one bend, subtract once.The K-factor in sheet metal bending represents the ratio between the thickness of the metal and an invisible line called the “neutral axis.” . (BA) by using the K , Bend Radius (R), Bend Angle (A) and Material Thickness using the formula below. BA=Pi*(R+K*T)*A/180. In this formula: K represents the K-factor. BA is the bend allowance. A is .

Analysis of bending sheet metal parts with large radius. The multi-step forming process is a sophisticated technique for achieving large-radius bends in sheet metal using smaller radius punches. This method’s .Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a .

sheet metal inside bend radius

Bends up to 1 1/4" of Sheet Metal From 90° to 180° - Ideal for Hems The Wuko Bender 4040 is an ideal tool to create hems. It features a thin bending wheel, which allows for bends from 90° up to 180°.Another great tool from the Wuko Arsenal.Wuko benders are a must have tools for metal roofers, those bending metal without a brake / box brake and those making radius roof panels . Common sheet metal materials include stainless steel, galvanized steel, tinplate, copper, aluminum, and iron. This article primarily analyzes the basic principles of sheet metal product design. 1. Minimum Bending Radius for Sheet Parts. When bending sheet parts, if .Similar to tucking the corners of a bedsheet, these benders twist and wrap the metal into triangle-shaped folds to form corners. Finish the fold by creasing it with a regular hand-held sheet metal bender. Style A benders have a longer throat depth for making deeper corners. They create corners in any angle. Style B benders form precise 45° or . Sheet metal bending to a radius with a metal box brake

A: Bend radius measurements for sheet metal parts and sections can be taken using a radius gauge or caliper measuring center-bend rise and centreline-chord thickness where applicable. In certain conditions, 3D scanning technologies can .

Sheet Metal Bend Radius Guidelines Here are a few key concepts to know about designing for sheet metal. Brackets, covers, cabinets, chassis, electrical enclosures. These and countless other sheet metal components might seem fairly simple to manufacture, but achieving part accuracy involves some fairly complex bending calculations. That’s . Therefore, the bending inner radius of our sheet metal parts is typically 0.2. While this radius is sufficient for ordinary low-carbon steel plates, rust-proof aluminum plates, brass plates, and copper plates, it may not be suitable for high-carbon steel, hard aluminum, and super-hard aluminum. In these cases, a rounded corner of 0.2 may cause .These are no “next-best” benders. Metal Benders by Malco bring the best of metal bending right to the job site with lightweight and versatile solutions. They’re precise, highly-durable and easy to use. Form 0–100-degree bends on straight or curved panels of any length.The bend radius is a critical parameter in sheet metal fabrication, dictating the minimum radius one can bend a metal sheet without significant deformations. Calculating the correct bend radius is essential for ensuring the structural integrity and aesthetic of the finished product. Calculating Bend Radius in Air Forming

IV. Press Brake Bend Radius Calculation. The 8 times rule is a general guideline for determining the V-shaped die opening, suggesting that the V-die opening should be 8 times the material thickness. However, there is no exact formula for determining the ideal bend radius for sheet metal, but under certain specified force conditions, the bend radius can be estimated . Otherwise roll bending and tube bending are also option to do the sheet metal bending without using metal brake and accessories. 6 Key Tips of Bend Metal Sheet . Tips to bend metal sheet are having proper metal bending tools, radius profile, sheet metal bending tips and angle gauge. 6 key tips are as follow: Calculate Bend Allowance

TayMac 1-Gang Extra Duty® Weatherproof Electrical Box Cover- the ultimate outdoor outlet cover that checks all the boxes when it comes to performance. Seamlessly blending with any siding type, it's perfect for new or old installations.

radius bender sheet metal|maximum thickness sheet metal bending