sheet metal pulley manufacturing process A stamped pulley is a type of pulley that is created by stamping a flat sheet of metal into the desired pulley shape. The stamping process involves pressing the metal sheet into a mold or die that has the shape of the pulley. A CNC (Computer Numerical Control) machine is a piece of equipment that uses computer-controlled software to automate machining processes. They are used to cut, drill, and shape materials with high precision, making them ideal for the mass production of identical components and complex parts.

0 · types of pulleys and belts

1 · rubber pulley belt

2 · pulleys and belts examples

3 · pulleys and belts

4 · pulley belt diagram

5 · leather pulley belt diagram

6 · leather pulley belt

What is Sheet Metal Processing? "Sheet metal" in sheet metal processing refers to thin metal plates, which can be processed by stretching, stamping, bending, etc., and the thickness is usually less than 6mm.

types of pulleys and belts

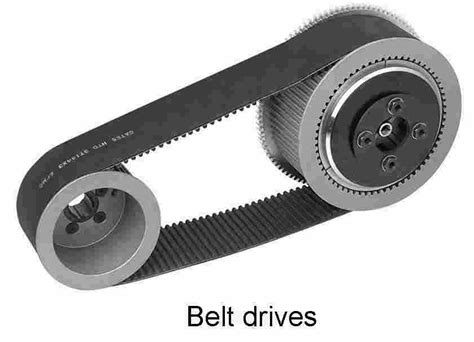

Pulleys and belts and sprocket and chain systems are common methods of power transmission in machines. They are used to transfer rotational motion and torque from one shaft to another shaft, usually with different speeds or diameters.

A method of manufacturing precise sheet metal made poly-V pulleys with poly-V grooves, being uniform in thickness of peripheral wall and free of reduction of mechanical strength, by a step.

A stamped pulley is a type of pulley that is created by stamping a flat sheet of metal into the desired pulley shape. The stamping process involves pressing the metal sheet into a mold or die that has the shape of the pulley.1. INTRODUCTION. In this, basically pulley is manufacture by using sheet metal forming process. This will be overcoming the disadvantage of Casting Pulley. By using Sheet metal forming .

Capitol Stampings offers a diverse platform of drive pulleys, sheaves, composite pulleys, and idler pulleys custom engineered for your specific application. Stamped, split steel or composite are the pulley manufacturing options .A V-pulley manufacturing process, comprising the following steps: forming a pulley by integrally forming a cylindrical pulley blank (1); machining a V-shaped belt groove, cutting the external.Summary of proven methods of production of pulleys are outlined as follows: (a) Press forming of a sheet metal for the production of a V-belt pulley [1, 7]; (b) Production of multi-stage pulley .Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques.

rubber pulley belt

The V-pulley manufacturing process includes the following steps: a. forming a cylindrical pulley body; b. machining V-belt grooves by removing certain portion of outer surface of the pulley.We are a Technologically advanced International Joint venture having experienced capabilities in the manufacturing of precision sheet metal components whether it be in Stampings, Formed or multiple component . a manufacturing method for a pulley made of sheet metal for toothed belts is disclosed in Japanese Patent Laid-Open, No. 177457/1982, which has the disadvantages that for toothed pulleys, the wall thicknesses of both shoulder sections in the pulley tooth section are extended by 60% of their material plate thickness so that a perfect tooth shape is difficult to .

Fig-1: Sheet metal Pulley Process Flow 4. CONCLUSIONS From this above research paper concluded that Spinning process is the best method for, producing the groove on sheet metal pulley. By using sheet metal it Produces Simple or Complex shapes easily & it improve RPM & load carrying capacity & also it reduces the weight & cost of pulley. 5.Process; Tooling; World of Pulleys; Contacts; . Pioneer in Sheet metal Spun Pulleys in India. Entire range of pulleys – Folded, Split and Poly “V” . (AHCPL) is an IATF 16949:2016 & ISO 9001:2015 certified company, with close to 7 .Process; Tooling; World of Pulleys; Contacts; . Pioneer in Sheet metal Spun Pulleys in India. Entire range of pulleys – Folded, Split and Poly “V” . (AHCPL) is an IATF 16949:2016 & ISO 9001:2015 certified company, with close to 7 decades of cold forming, tool design & sheet metal manufacturing expertise, aimed at providing world class .

manufacturing process sheet metal toothed belts metal pulley pulley Prior art date 1984-06-12 Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.) Expired Application number DE8585107067T Other languages .

In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. Sheet Metal Operations. Following are the 9 different types of sheet metal operations: Shearing Operations; Blanking OperationsUS4605388A US06/742,184 US74218485A US4605388A US 4605388 A US4605388 A US 4605388A US 74218485 A US74218485 A US 74218485A US 4605388 A US4605388 A US 4605388A Authority US United States Prior art keywords sections flange pulley section circumferential Prior art date 1984-06-12 Legal status (The legal status is an assumption and is .A sheet metal pulley having a generally circular base with an upstanding circumferential flange. The flange is formed to provide teeth for engaging a toothed belt. The outer tooth sections are separated by tooth bottom sections and these sections are interconnected by intermediate walls. Reinforcing ribs extend circumferentially on the inside of the outer tooth sections between the .

Progressive Work and Tool & Die Design. Progressive stamping is a metal forming process that uses a series of dies to create complex parts from sheet metal. The sheet metal is fed into the press by a coil or strip, and each die station performs a different operation on the metal, such as cutting, bending, punching, or drawing.US4605388A US06/742,184 US74218485A US4605388A US 4605388 A US4605388 A US 4605388A US 74218485 A US74218485 A US 74218485A US 4605388 A US4605388 A US 4605388A Authority US United States Prior art keywords sections flange pulley section circumferential Prior art date 1984-06-12 Legal status (The legal status is an assumption and is .

EP0164707B1 EP85107067A EP85107067A EP0164707B1 EP 0164707 B1 EP0164707 B1 EP 0164707B1 EP 85107067 A EP85107067 A EP 85107067A EP 85107067 A EP85107067 A EP 85107067A EP 0164707 B1 EP0164707 B1 EP 0164707B1 Authority EP European Patent Office Prior art keywords sections pulley flange section circumferential Prior art date 1984-06-12 .IT8323483A1 - "Process for manufacturing multi-grooved sheet metal pulleys and product obtained" - Google Patents "Process for manufacturing multi-grooved sheet metal pulleys and product obtained" Info Publication number . 238000004519 .

EP0164707B1 EP85107067A EP85107067A EP0164707B1 EP 0164707 B1 EP0164707 B1 EP 0164707B1 EP 85107067 A EP85107067 A EP 85107067A EP 85107067 A EP85107067 A EP 85107067A EP 0164707 B1 EP0164707 B1 EP 0164707B1 Authority EP European Patent Office Prior art keywords sections pulley flange section circumferential Prior art date 1984-06-12 .

pulleys and belts examples

manufacturing process sheet metal toothed belts metal pulley pulley Prior art date 1984-06-12 Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.) Expired Application number DE8585107067T Other languages .US4605388A US06/742,184 US74218485A US4605388A US 4605388 A US4605388 A US 4605388A US 74218485 A US74218485 A US 74218485A US 4605388 A US4605388 A US 4605388A Authority US United States Prior art keywords sections flange pulley section circumferential Prior art date 1984-06-12 Legal status (The legal status is an assumption and is .US4605388A US06/742,184 US74218485A US4605388A US 4605388 A US4605388 A US 4605388A US 74218485 A US74218485 A US 74218485A US 4605388 A US4605388 A US 4605388A Authority US United States Prior art keywords sections flange pulley section circumferential Prior art date 1984-06-12 Legal status (The legal status is an assumption and is .A method of manufacturing sheet metal made poly-V pulleys as set forth in claim 5 or 6, wherein the pressing plane of said auxiliary forming roller to press the peripheral wall is formed in an outward projecting arc plane, and the peripheral wall on which said curvature has been formed is pressed by said auxiliary forming roller to thicken the .

US4605388A US06/742,184 US74218485A US4605388A US 4605388 A US4605388 A US 4605388A US 74218485 A US74218485 A US 74218485A US 4605388 A US4605388 A US 4605388A Authority US United States Prior art keywords sections flange pulley section circumferential Prior art date 1984-06-12 Legal status (The legal status is an assumption and is .EP0164707B1 EP85107067A EP85107067A EP0164707B1 EP 0164707 B1 EP0164707 B1 EP 0164707B1 EP 85107067 A EP85107067 A EP 85107067A EP 85107067 A EP85107067 A EP 85107067A EP 0164707 B1 EP0164707 B1 EP 0164707B1 Authority EP European Patent Office Prior art keywords sections pulley flange section circumferential Prior art date 1984-06-12 .US4605388A US06/742,184 US74218485A US4605388A US 4605388 A US4605388 A US 4605388A US 74218485 A US74218485 A US 74218485A US 4605388 A US4605388 A US 4605388A Authority US United States Prior art keywords sections flange pulley section circumferential Prior art date 1984-06-12 Legal status (The legal status is an assumption and is .EP0164707B1 EP85107067A EP85107067A EP0164707B1 EP 0164707 B1 EP0164707 B1 EP 0164707B1 EP 85107067 A EP85107067 A EP 85107067A EP 85107067 A EP85107067 A EP 85107067A EP 0164707 B1 EP0164707 B1 EP 0164707B1 Authority EP European Patent Office Prior art keywords sections pulley flange section circumferential Prior art date 1984-06-12 .

US4605388A US06/742,184 US74218485A US4605388A US 4605388 A US4605388 A US 4605388A US 74218485 A US74218485 A US 74218485A US 4605388 A US4605388 A US 4605388A Authority US United States Prior art keywords sections flange pulley section circumferential Prior art date 1984-06-12 Legal status (The legal status is an assumption and is .

EP0164707B1 EP85107067A EP85107067A EP0164707B1 EP 0164707 B1 EP0164707 B1 EP 0164707B1 EP 85107067 A EP85107067 A EP 85107067A EP 85107067 A EP85107067 A EP 85107067A EP 0164707 B1 EP0164707 B1 EP 0164707B1 Authority EP European Patent Office Prior art keywords sections pulley flange section circumferential Prior art date 1984-06-12 .EP0164707B1 EP85107067A EP85107067A EP0164707B1 EP 0164707 B1 EP0164707 B1 EP 0164707B1 EP 85107067 A EP85107067 A EP 85107067A EP 85107067 A EP85107067 A EP 85107067A EP 0164707 B1 EP0164707 B1 EP 0164707B1 Authority EP European Patent Office Prior art keywords sections pulley flange section circumferential Prior art date 1984-06-12 .US4605388A US06/742,184 US74218485A US4605388A US 4605388 A US4605388 A US 4605388A US 74218485 A US74218485 A US 74218485A US 4605388 A US4605388 A US 4605388A Authority US United States Prior art keywords sections flange pulley section circumferential Prior art date 1984-06-12 Legal status (The legal status is an assumption and is .EP0164707B1 EP85107067A EP85107067A EP0164707B1 EP 0164707 B1 EP0164707 B1 EP 0164707B1 EP 85107067 A EP85107067 A EP 85107067A EP 85107067 A EP85107067 A EP 85107067A EP 0164707 B1 EP0164707 B1 EP 0164707B1 Authority EP European Patent Office Prior art keywords sections pulley flange section circumferential Prior art date 1984-06-12 .

US4605388A US06/742,184 US74218485A US4605388A US 4605388 A US4605388 A US 4605388A US 74218485 A US74218485 A US 74218485A US 4605388 A US4605388 A US 4605388A Authority US United States Prior art keywords sections flange pulley section circumferential Prior art date 1984-06-12 Legal status (The legal status is an assumption and is .

pulleys and belts

frp junction box with canopy

Metal-enclosed switchgear is typically less expensive, has a smaller footprint, and can offer a wide variety of bussing and connections options compared to metal-clad switchgear. Above is a typical outdoor, 15kV switch lineup with an incoming and bus transition section.

sheet metal pulley manufacturing process|rubber pulley belt